THE TEST OF A NEW PARAFFIN VAPORIZER.

Page 19

Page 20

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A 50-mile Road Run Using a Low-grade Paraffin Fuel.

1X/rANY MORE or less successful ..L.Y.Lattempts have been made to induce an orthodox petrol engine to run on heavy fuels, such as cheap paraffins and the lighter gas oils. Such fuels can now be purchased in bulk at prices ranging from 7d. to Pd. per gallon, representing a considerable saving upon the present price of petrol. This saving may, to some extent, be discounted by the inferior miming of the engine and decrease in efficiency when a heavy fuel is used, but this decrease need not be great if the fuel is properly vaporized.

The production of a. dry vapour under all running conditions is really the whole battle, the troubles usually met with when paraffin is used being almost wholly due to liquid fuel entering the cylinders. When the vaporization is correct lubrication troubles are not encountered, tho engine does not evidence the same tendency to knocking, and the cylinders will he as clean internally as when running on petrol.

An exhaust-heated vaporizer cannot be expected to function perfectly, for the simple reason that, when the engine is running light, the heat in the exhanst will be insufficient. to provide for correct vaporization when the throttle is once again opened. For this reason the patentees of the Saunt vaporizer under review have broken away from the idea of exhaust heating' and provide a paraffin burner to heat, their vaporizer.

At first sight this might be considered a retrograde step, but when it is pointed out that the provision of a burner enables the vaporizer to supply the correct amount of heat for all conditions of load and speed, and that no petrel whatever need be carried on the car, it will be seen that there is much to be said for this. solution to the problem. Duplicate tanks carrying petrol and paraffin are not very satisfactory, because there

will always be a tendency for the driver to use more petrol than he should, so that it is a distinct advantage. to carry heavy fuel only, which is used both in the engine and the burner. Incidentally, the burner consumes from one or two pints per hour, according to the i,everity of the running conditions. We are not at. present permitted to describe the internal construction of the vaporizer, as the patents are not yet completed. It will be seen, however, that it consists of a casing -with the burner at the bottom, vaporizer in the middle and throttle and float chamber at the top, where the inlet pipe is also connected. The engine suction draws the heavy fuel from the float chamber through the vaporizer, and also draws a spray of water from a second float chamber into the inlet pipe. The engine can be run without water, but it is advisable to maintain the suPply, as this prevents harsh running and improves the power available. In addition, it is well known that water preserves tbe valves from burning anti reduces carbon deposit.

Ivor the purpose of demonstration

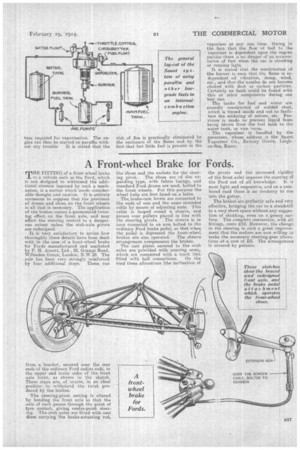

• the vaporizer is fitted to an old 25 h.p. Berliet car, which has a four-cylinder aide-by-side-valve engine of 4 ins, bore by 5 ins. stroke. The compression pressure is 80 lb. per sq. in., and the engine has not been altered. but for the new arrangement of the inlet pipe and the discarding of the petrol carburetter. The car has been running for over two years on low-grade paraffin, and no trouble with lubrication has been experienced.

X36 Our road test consisted of a run from London to Basingstoke, on the Southampton Road. The roads from Marble Arch through Kensington and Hammersmith were, as usual, congested with traffic, and formed a good test of the flexibility of the engine. The pick-up, power and slow running left nothing to be desired, and there. was practically no vapour discernible from the exhaust. Furthermore, the characteristic smell of paraffin was entirely absent, these facts showing that the vaporization was perfectly 'satisfactory.

Speed and Hilt-climbing Power Satisfactory.

The run was continued through Staines, a good speed being maintained on the clear road, 45 m.p.h. being exceeded during several periods. The engine proved adequately powerful on paraffin, pulling extremely well considering that the ear and its load weighed over 2itons. On Egbam Hill a stop was made for the purposes of a photograph, and the restart on the steepest, section presented no difficulties whatever. Previously, the car had been left standing for over an hour while lunch was obtained at Staines, and the engine started at the first pull-up, although it had become almost cold.

The run was continued so far as Basingstoke, and confirmed the impressions previously formed as to the qualities of the vaporizer. A consumption test was not carried out for two reasons —firstly, the car was not fitted with special testing tanks, so that any test would not have been really accurate; and, secondly, the total weight was not accurately known, and the engine did not really correspond to the power unit of a modern commercial chassis. We were told that on the car in question the m.p.g obtained was about 16. At a later date we hope to carry out a test on a lorry fitted with this vaporizer, and will then be able to give the details of its construction.

The. writer drove the car over a por,

tion of the run and found that the engine was as flexible and easy to handle as although it were running on petrol. There was never any trace of knocking or harshness. A sample of the fuel was drawn off at the conclusion of the run, and was found to consist of low-grade paraffin with a 'small proportion of light gas-oil.

Air pressure is relied upon to -force the water and fuel from the tanks to. the float chambers, 2 lb. to 3 lb.' per sq. in. being sufficient for this purpose. The fuel for the burner requires a higher pressure, ranging from 5 lb. to 15 lb. per sq, in., according to the load on the engine. Whilst mechanical air pumps could easily he provided if required,the inventors consider that hand-operated plunger pumps are satisfactory, and on the car in question only a few strokes every half-hour or so were required to maintain the pressure. When running on full load the noise of the burner could just be heard above the hum of the engine, but was not at all objectionable.

When the burner is lighted in the morning with the engine dead Cold a few minutes suffice to attain the tempera titre required for vaporization. The engine can then be started on paraffin with out. any trouble. It is stated that the risk of fire is practically eliminated by the enclosure of the flame and by the fact that but little fuel is present in the vaporizer at any one time. Owing to the fact that the flow of fuel to the vaporizer is dependent upon the engine suction there is no danger of an accumulation of fuel when the car is standing or running light.

It is stated that the construction of the burner is such that the flame is independent of vibration, damp, wind, etc., and that the nozzles do not become choked with dust or carbon particles. Certainly no fault could be found with this or other components during our test. run.

The tanks for fuel and water are soundly constructed of welded steel, which is tinned inside and out to facilitate the soldering of unions, etc. Provision' is made to, prevent liquid from being blown from the fuel tank to the water tank, or vice versa.

The vaporizer is handled by the patentees, whose address is the Sannt Vaporizer Co., Rectory Grove, Leighon-Sea, Essex.