euro truck test

Page 27

Page 28

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

By Graham Montgomerie

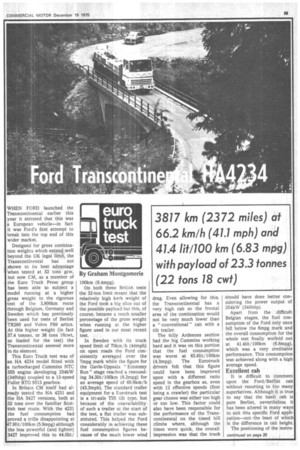

WHEN FORD launched the Transcontinental earlier this year it stressed that this was a European vehicle—in fact it was Ford's first attempt to break into the top end of this wider market.

Designed for gross combination weights which extend well beyond the UK legal limit, the Transcontinental has not shown to its best advantage when tested at 32 tons gcw, but now CM, as a member of the Euro Truck Press group has been able to subject a model running at a higher gross weight to the rigorous test of the 3,800km route through Belgium, Germany and Sweden which has previously been used for tests of Berliet TR280 and Volvo F89 artics. At this higher weight (in fact 37.4 tonnes, or 36 tons 16cwt, as lOaded for the test) the Transcontinental seemed more in its element.

This Euro Truck test was of an HA 4234 model fitted with a turbocharged Cummins NTC 355 engine developing 254kW (340bhp) coupled to a 13-speed Fuller RTO 9513 gearbox.

In Britain CM itself had already tested the HA 4231 and the HA 3427 versions, both at 32 tons over the familiar Scottish test route. With the 4231 the fuel consumption had proved a trifle disappointing at 47.91it/100km (5.9mpg) although the less powerful (and lighter) 3427 improved this to 44.01it/ 100km (6.4mpg).

On both these British tests the 32-ton limit meant that the relatively high kerb weight of the Ford took a big slice out of the possible payload but this, of course, became a much smaller percentage of the gross weight when running at the higher figure used in our most recent test.

In Sweden with its truck speed limit of 70km/h (44mph) on open roads the Ford consistently averaged over the 7mpg mark while the figure for the Gavle-Uppsala "Economy Run" stage reached a resounding 34.31it/100km (8.2mpg) for an average speed of 69.9km/h (43.3mph). The standard trailer equipment for a Eurotruck test is a tri-a.xle Tut tilt type, but because of the unavailability of such a trailer at the start of the test, a flat trailer was substituted. This helped the Ford considerably in achieving these fuel consumption figures because of the much lower wind drag. Even allowing for this, the Transcontinental has a very high cab so the frontal area of the combination would not be very much lower than a " conventional " cab with a tilt trailer.

The hilly Ardennes section had the big Cummins working hard and it was on this portion that the fuel consumption was worst at 65.81111100km (4.3mpg), The Eurotruck drivers felt that this figure could have been improved upon with a different ratio speed in the gearbox as, even with 12 effective speeds (first being a crawler) the particular gear chosen was either too high or too low. This factor could also have been responsible for the performance of the Transcontinental on the timed hill climbs where, although the times were quick, the overall impression was that the truck should have done better considering the power output of 254kW (340bhp).

Apart from the difficult Belgian stages, the fuel consumption of the Ford only once fell below the 6mpg mark and the overall consumption for the whole test finally worked out at 41.41it/100km (6.8mpg), which was a very creditable performance. This consumption was achieved along with a high average speed.

Excellent cab

It is difficult to comment upon the Ford/Berliet cab without resorting to too many superlatives. Although it is true to say that the basic cab is pure Berliet, nevertheless it has been altered in many ways to suit this specific Ford application—not 'the least of which is the difference in cab height.

The positioning of the instru merits has been well thought out and I particularly like the "three O'clock" direction for the gauge needles when all systems are functioning correctly. The swivel vents for cab ventilation are situated in a panel above the top of the windscreen, which means that the driver can adjust them to blow on to his face rather than up his sleeve as invariably happens when •the vents are mounted on the dash.

The Eurotruck group were, in the main, rather disappointed by the ride of the Ford, feeling that it was on the soft side. Although the set up gave an extremely comfortable ride we all felt that it detracted from the driver's confidence when cornering— a situation probably aggravated by the relatively high cab.

On straight roads, whatever the surface, the combined suspension systems of the truck, cab and seat eliminated most of the bounces although if the surface was very bad, the motion took a long time to die down.

The steering also came in for some criticism as being oo vague in the straight-ahead position, but this is a complaint which could be levelled at many other heavy trucks. On the twisty stages of the route the steering could not be faulted, being both light and accurate, which made the Transcontinental very easy to handle. It was a pity that the straightline precision was not of the same standard.

Test summary

The Transcontinental is an extremely well thought-out piece of engineering—all the more creditable as it is Ford's first attempt at the heavy end of the European market.

In terms of driver comfort it almost goes too far with its soft ride, but this is a matter of individual driver opinion. Fuel consumption is not a matter of opinion, it concerns indisputable figures and, in this area, the performance of the Ford was excellent with an averail figure of 41.41it/100km (6.83mpg).

The main selling points which Ford is stressing for the Transcontinental — durability and reliability — can be ,ascertained only when the first customer units start clocking ip the miles in service.

Discussion with Ford

THE Transcontinental discussion was held between the Eurotruck group and representatives from both Ford and Cummins. On the engineering side were Mr Walter Manning (manager, chassis and transmission engineering) and Mr Colin Bunting (vehicle evaluation engineer) from Ford of England. Mr Nick Ludwig (manager, heavy truck plans) of Ford of Europe covered the marketing aspects. Mr George Allen (manager, application accounts — Europe) was on hand Ito represent Cummins.

A lot of discussion took place on the transmission specification of the Transcontinental as the two Eurotruck professional drivers—their usual mounts are Volvos — thought that the Fuller gearbox had a baulky change in the lower gears. Mr Manning thought that this was probably due to the driver's initial unfamiliarity with the box. This was a situation aggravated by the clutch brake on the Fuller gearbox. Although it could be used to great advantage when selecting a, gear from rest or for single fast upchanges it made the change more difficult if the driver pressed the pedal too far on a normal change (the clutch brake only coming in to operation at the very bottom of the pedal travel).

Commenting on the fact that several times the split change had activated itself before the driver had intended, Mr Manning said that, because the Fuller went from direct to overdrive and vice versa by a change in the applied torque, it was possible for a bump in the road to produce a big enough torque change via the tyres for the system to change gear. In effect it was possible to use the split change like an Eaton axle without using the clutch, so it was important not to preselect too early.

When asked about the reasons for specifying the Fuller gearbox, the Ford reply was that the other choices fall short of the durability requirements. Mr Manning said : "With a synchro box the thermal loading of the synchromesh cones, especially in the lower gears, means that they go out too early. It is therefore a cost of ownership problem balanced against the necessity for driver training on the constant-mesh gearbox."

The Cummins engine had required topping up with oil on a couple of occasions and when this was brought up Mr Allen said that this was completely out of character for this particular unit. Asked if the change to a lower oil rating had had any effect, the Cum mins reply was that the oil specification depended upon the ambient temperature (about 4°C or 40°F being the dividing line) but that this change in SAE rating should not affect the oil consumption. The only recognisable difference would be when starting from cold.

The subject of the cooling system brought out some questions on the radiator size and inbuilt safety margins. The radiators throughout the Transcontinental range are the same size owing to rationalisation and, answering the query on safety margins, MT Allen said that it should be possible to lose about 11 litres (2.4gal) from the 46-litre (10.1gal) circuit without the need to shut down.

The larger part of the discussion was taken up with the suspension and steering Characteristics of the Transcontinental. Although the Eurotruck members thought that the ride was comfortable enough, they were all in agreement that perhaps it was a little too soft, with the high cab aggravating the effect as far as the driver was concerned. MT Manning explained : "The suspension was designed to cater for all surface conditions, but also laden and unladen conditions. I think we can claim that the gap between laden and unladen ride has been narrowed considerably although, in lowering the frequencies over bad roads, a sacrifice had to be made when fully laden on good roads— but we still believe it is a good ride.

"The Berliet system, we found, gave an unacceptable ride in the unladen condition. If it had worked it would have saved us a lot of money and engineering " Elaborating on the laden/unladen relationship, Mr Manning commented that with tankers especially, which spend 50 per cent of 'their running time empty, the unladen ride was a very important point. Ford had moved away from a harsh, taut suspension which gave the driver confidence. But he thought that driver familiarity would improve the situation.

I asked if it was possible to arrive at a condition where, for example, the seat suspension could get out of phase with the cab suspension. Mr Manning replied that while it was theoretically possible to find a surface condition which would cause this "we haven't found it yet I " The steering system was criticised mildly by the Eurotruck members who felt that the steering was rather vague. The Ford reply was that the steering box needed to be run in to give its best performance. The torsion-bar control of the steering valve was influenced by the build-up in friction of the various components and, as the friction gradually disappeared during running in, the torsion bar could react as it was designed to.

"We think we have the right torsion bar for the job. When a truck veers slightly from its true path, the situation can get worse as the driver overcorrects. It is the first diversion that we have to cure."

To get the required durability from the power steering layout, the Ford designers had set themselves the target of getting the pressure in the system below 8275kNisqm (1200psi). "The seal manufacturers say they can give this durability but we don't think so. Hence th::, auxiliary ram layout."