AT THE St OF THE G

Page 42

Page 43

Page 44

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

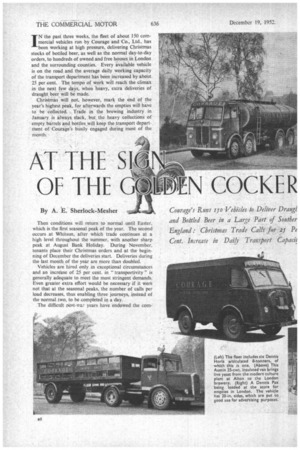

By A. E. Sherlock-Mesher Courage's Runs ijo Vehicles to Deliver Drat's) and Bottled Beer in a Large Part of Souther England.' Christmas Trade (ails for-2f Pe Cent. Increase in Daily Transport Capacil

/ N the past three weeks, the fleet of about 150 com mercial vehicles run by Courage and Co., Ltd., has been working at high pressure, delivering Christmas stocks of bottled beer, as well as the normal day-to-day orders, to hundreds of owned and free houses in London and the surrounding counties. Every available vehicle is on the road and the average daily working capacity of the transport department has been increased by about 25 per -cent. The tempo of work will reach the climax in the next few days, when "heavy, extra deliveries of draught beer will be made.

Christmas will not, however, mark the end of the year's highest peak, for afterwards the empties will have to be collected. . Trade in the brewing industry in January is always slack, but the heavy collections of empty barrels and bottles will keep the transport department of Courage's busily engaged during most of the month.

Then conditions will return to normal until Easter, which is the first seasonal peak of the year. The second occurs at Whitsun, after which trade continues at a high level throughout the summer, with another sharp peak at August Bank Holiday. During November, tenants place their Christmas orders and at the beginning of December the deliveries start. Deliveries during the last month of the year are more than doubled.

Vehicles are hired only in exceptional circumstances and an increase of 25 per cent. in " transportivity " is generally adequate to meet the most stringent demands. Even greater extra effort would be necessary if it were not that at the seasonal peaks, the number of calls per load decreases, thus enabling three journeys, instead of the normal two, to be completed in a day.

The difficult post-war years have endowed the corn: pany with a mixed fleet, which comprises 104 Dennis, Austin, Bedford and Vulcan 5-tonners, six Leyland tankers, six Dennis Horla articulated 8-tonners, nine Bedford-Scammell articulated 8-tonners, five Thornycroft 6-tonners, four Scammell 3-ton mechanical horses, ten Austin 25-cwt. 'and six miscellaneous vehicles. It is, however, being standardized on Dennis lorries, with Leyland-Butterfield 40-barrel and 80-barrel tankers. One of the attractions of the Dennis Pax normal-control 5-tonner is the comfortable three-man cab, in which two draymen sit about 6 ins, behind the driver, so that he has ample elbow-room and good all-round vision.

The 5-tonner, which is the backbone of the fleet, is the most convenient transport unit for the company. A larger vehicle would take too long to load and the two journeys a day which economic operation in London demands, might be impossible.

The road tankers have been built to match the static tanks of the breweries and their capacities are, it will, be observed, in units of 40 barrels. For technical reasons, it is desirable that the static tanks should he emptied completely and a vehicle should, therefore, be capable of taking the whole contents of either one or two of them. The tank wagons have proved to be economical to operate and, since their introduction between 1947 and 1950, have repaid their initial outlay. Eighty-barrel tankers operate between the breweries in London and Alton and '40-barrel and 80-barrel models between London and the bottling stores at Kingston.

An Austin 25-cwt. insulated van is used to carry live yeast from Alton', where there is an up-to-date culture plant, to London. Yeast is, of course, a vital ingredient of beer and its condition is extremely important. Its temperature in transit must be strictly controlled and the use of the insulated van has been most successful.

Apart from the delivery vehicles, the transport department operates vans for the advertising, maintenance and engineering departments. Because of the comparatively small mileages 'covered by the whole fleet, 87+ per cent. of the vehicles have petrol engines. The average annual mileage per vehicle is 12,000 and the total for the fleet, including travellers' cars, is in the region of 24m.

Bodywork is of two main types. Half the lorries operated in London have 20-in, drop sides, the main

purpose of which is to carry advertising matter. These vehicles handle bottled beer, much of which is contained in interlocking steel crates which can be stacked safely without relying on the body sides to steady them. The rest of fife London delivery vehicles, which are used mainly for transporting beer in casks, have rigid sides 3 ft. 6 ins, high, with tail gates.

A great deal of research has been undertaken in an effort to find an ideal body. Many of the " draught " lorries have Sparshatt light-alloy bodies to reduce the unladen weight below 3 tons. Some bodies have metal frames with wooden floors, others have wooden frames and metal floors, and some are entirely of metal. The maintenance of lorry floors is one of the brewer's biggest problems, because they have to withstand the impact of barrels weighing about 4 cwt. each and having sharp chines. In Courage's experience, metal floors are most ' suitable for lorries carrying bottles and wood for those handling casks.

Mobile Advertising

Since the war, the company has undertaken a vigorous advertising campaign, in which the transport fleet plays an important part. The vehicles themselves, with their smartly painted Panhard red bodies, gold classical lettering and vermilion wheels, are a credit to any operator. ln addition, each carries on the cab roof a splendid effigy of a golden cockerel, which is Courage's trade mark derived• from the family's original coat of arms.

Some of these sprightly birds are connected to tape-recording machines and can be induced to crow loudly --a popular diversion at horse shows, carnivals and on other festive occasions. This year's Royal Show, at Newton Abbot, Was a justifiable occasion for crowing, for a team of four Clydesdales (the company still has 16 horses) ikon the Vender award in its class. The :latest vehicles also have a moulded aluminium cockerel incorporated in the centre of each side panel, giving them a distinctive touch.

The company has two main breweries. One is at Horselydown Lane in the congested Tower Bridge area of London, where 90 -vehicles are based. The other brewery is 56 miles away at Alton, Hants, where the speciality is pale ale, and there is an interchange of the products of the two breweries. This explains the introduction of the tankers, which, incidentally, replaced rail transport.

Mixed Loads

Forty vehicles are based at Alton, most of them being 5-tonnerS, although to meet the special local conditions some 8-tonners and 12-tanners are used. • Unlike the London-based lorries, they carry mixed loads and all have high sides.

The bottling store at Kingston is new and is claimed to be one of the most up to date in the country. Twenty vehicles are based on it. Two or three vehicles are also stationed at a wine and spirit store in Windsor.

Thus, there are three main centres of distribution, the radius of each depending on its productive capacity, and the geographical layout tends towards a compact organization. The London brewery serves the Home Counties, including the Kent, Essex and Sussex coasts, and Alton deals with parts of Surrey, Hampshire, Buck

inghamshire and Berkshire. Kingston-based vehicles

• operate within a radius of 20 miles. The number of owned houses served by the fleet runs well into four figures, in addition to which a great many free houses and accounts are supplied. There are particularly heavy concentrations of houses in Dartford, London itself, parts of Hampshire, Windsor and Kingston.

a10 In both London and Kingston, separate vehicles are used for draught and bottled beer. In the congested Metropolitan area, short, quick drops are favoured and, as a rule, each house receives two deliveries of draught and one of bottled beer each week. In the country, deliveries are made once a week, as mixed loads are carried.

Policy in this connection is dictated partly by transport working conditions, which vary"widely. Many of the houses are within a short radius in the heart of London and the times.of delivery are controlled by the police. Some of the big houses occupy corner sites, where the problem of avoiding obstruction is particularly acute, and, in certain instances, the police require deliveries to be completed by 9 a.m. As the staff begins work at 7 a.m., there are nearly two hours for travelling and dropping the load.

In London, the average mileage per day is about 50, with four or five drops, depending on the size of the vehicle and the trade of the houses. By contrast,a

large proportion of the trade covered by the. Alton brewery is spread over a radius of 50-60 miles and individual daily mileages are higher than in London,. although journey times are not necessarily 'much longer.

The round trips from London to the south' and eastcoast holiday resorts are up to about 150 miles long and, making two or three deliveries en route,• they can in summer be completed comfortably in the working day.

As a rule, delivery rounds are made up on a daily basis, having regard to a combination of weight and time, rather than to a fixed routine. Each house has its pre-arranged delivery day. There is no set rota for journeys, although on the longer runs vehicles take their turn.

Apart from physical operating conditions, transport is greatly influenced by changes in public taste. Since the war, there has been a greatly increased demand, in the south of England, for bottled beer, instead of draught beer. As the weight of any given quantity of bottled beer is more than twice that of draught, a greater number of vehicles is now necessary to handle the traffic. Moreover, it is much more difficult to deliver 48 dozen half-bottles, with the corresponding empties to be returned, than a cask.

Conveyors, combined with hand trucks, enable 5 tons of bottled beer to be loaded in 20 minutes. Casks present no problem, as they are brought up to the store on a conveyor and can be rolled directly on to the loading bank and from there straight into the lorry. Administration is presided over by Mr. Edward Courage, the transport director. Mr. H. Stevens, M.1.T.A., the transport manager, is responsible through the general manager to Mr. Courage for general policy, and has in his charge the whole system of dispatch, including the order office, invoicing and routeing. Mr. J. Thorp, M.I.R.T.E., A.I.T.A., the transport engineer, is responsible for vehicle maintenance and efficiency, and for all transport labour. The depots also come under head-office guidance, the Alton brewery having its own organization which is kept in close touch with London.

Consignment procedure is simple, but efficient. The order and dispatch offices are associated and are responsible for accounting up to the stage of producing typed, priced invoices. The system works on a day-to-day basis, orders received one day generally being dispatched the next. In emergencies, orders can, however, be dispatched on the day of receipt. "We can set a 5-ton vehicle on the road, loaded, together with the necessary documents, within 20 minutes of receiving an order," Mr: Stevens said with some pride. "The system is such that we can receive and put on the road orders at the rate of 100 an hour and this, in fact, we do every Monday morning,"

Costing System Cards

In the costing system, records of mileage, fuel and nil issues and mileage per gallon arc kept on cards, there being one card, with space for 12 weeks' daily entries, for each vehicle. Repairs are recorded on the fitter's sheet, which covers a week's work and provides for a description of the work chine, time occupied and the materials used. This information is transferred to a loose-leaf ledger in which each vehicle has a separate page containing its mechanical history, cost of repairs and registration particulars. Depreciation is accounted for in a stock book and tyres have their own history sheets_ The average life of a set of tyres is 40,00048,000 miles. Retreads are used on rear wheels, but new equipment is always fitted at the front. Fairly consistent annual mileages enable a time base to be used for maintenance, but Mr. Thorp does not believe in system for system's sake. Maintenance arrangements are flexible and are made by personal consultations, rather than by rule of thumb. Indeed, the whole business, which has been in operation under the Courage family since 1787, is founded on close human relationships.

Major Overhauls Every Four Years Nevertheless, each vehicle spends at least one day a month in the garage (corresponding to an interval of about 1,000 miles) for washing, greasing, the checking of gearbox and rear-axle oil levels and for general inspection. About once a year a top overhaul is undertaken, with a complete overhaul every four years, or at about 48,000 miles. Oil consumption and engine performance determine the work to be done, but a special watch is always kept on tyres, paintwork and lorry floors. Vehicles are repainted and revarnished on an average every 18 months to two years.

During peaks, when all the commercial vehicles are out, the workshops concentrate on overhauling exchanged units and on car maintenance.

The maintenance staff in London consists of a foreman, six fitters, four labourers and two boys, who undertake all mechanical work other than cylinder reboring and crankshaft regrinding. Large body repairs and repainting are normally done by contractors, primarily because of the limited facilities in the workshops, which were severely damaged by a flying bomb towards the end of the war. Maintenance services are also operated at Kingston, where the workshop is a model, and at the Alton brewery.

In its labour relations, the company upholds the high tradition of the brewing industry. The employees are well paid and those with long service receive non-contributory pensions. Two weeks to three weeks annual holiday is granted. Perhaps even more important than immediate pecuniary advantage, however, is the personal interest which all grades of management, from the directors downwards, take in the welfare of every man.