8 Tons 8 Hours 199Miles

Page 36

Page 37

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

By Laurence J. Cotton, m.i.R.T.E.

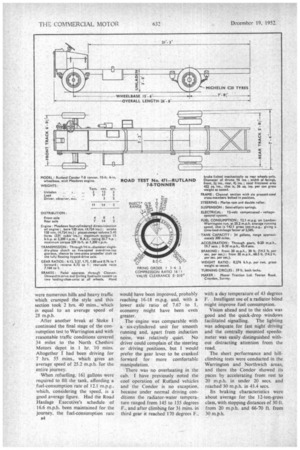

Meadows Four-cylindered Oil Engine in Rutland Condor Provides Good Pulling, Power Combined with Smooth Operation. Fuel-consumption Trial Staged Over a Normal Trunk Route II would take a lively vehicle to match the performance of the Rutland Condor 7-8-tormer in hill climbing or in its ability to maintain a high average speed over a long run. On a fuel-consumption test from London to Warrington, delivering the vehicle to North Cheshire Motors, Ltd., it climbed all hills, with one exception, in direct drive or third gear, and the 199-mile journey was accomplished in under eight hours' running time. The vehicle cruised comfortably at 45 m.p.h. for long spells.

Although a high-performance machine, it has a relatively small engine and is the only current production chassis in which the Meadows 5.43-litre unit is the standard power unit. The Condor is, apart from the make and type of engine, similar to the forward-control Eagle, Albatross and Stuka chassis built. by Motor Traction, Ltd., Croydon. The frame is basically similar and so are the running components.

"Square" Engine The Meadows four-cylindered direct-injection oil engine has a " square " bore-to-stroke ratio and is set to give 85 b.h.p. at 2,200 r.p.m. and 239 lb.-ft. torque is delivered at 1,200 r.p.m. An unusual feature is that out-of-balance secondary forces are counterbalanced by contrarotating weights driven at double engine speed by two shafts mounted below the crankshaft. These shafts are geared to the auxiliary train and transmit the drive to the weights below the centre main bearing.

Of integral design, the crankcase and cylinder block are made of cast iron, and wet-type cylinder liners are 0 used. Two cast-iron cylinder heads are fitted and renewable valve seats are provided for both inlet and exhaust valves. Other outstanding details include auxiliary drive gears at the flywheel end of the engine and a single belt at the front to drive the fan, water impeller, dynamo and exhauster.

The Simms fuel-injection pump. centrifugal governor and pumpoperating levers are contained in special assembly in the gear case. The Meadows device for automatic advance or retard of the fuel-injection point is installed.

A 14-in.-diameter single-dry-plate clutch and Meadows five-speed overdrive-top gearbox figure in the specification. This gearbox was designed for use with the fourcylindered unit and the ratios are nicely spaced for the varying work in trunk haulage. With constantmesh for four ratios, it is quiet in operation and the gear lever is light to manipulate.

Metallic Tyres

The vehicle tested was a longwheelbase model with a three-piece propeller shaft and Michelin Metallic C.20 tyres. It has a hypoid ax/e and Clayton Dewandre vacuumservo braking system, with Girling hydraulic operation.

A straight frame is employed, with bolted channel-section cross-members and a rear extension. The test chassis was intended for use with a special cattle-truck body which required an unusually long frame, provided by the 15-ft. 6-in, wheelbase and 7-ft. 5-in, rear overhang.

The standard bonnet affords ample space around the power unit to promote cooling and the electrical control panel and speedometer head are attached centrally at the front. where they are more accessible The engine oil pressure and brake vacuum gauges are attached to a panel at the head of the steeringcolumn tube.

The test chassis, lent by North Cheshire Motors, Ltd., Warrington, was equipped with a Bowyer threeseat, three-door cab. The single seats on the near side of the bonnet are arranged above, and in front of, the wheel-arch, with an individual door to each seat. When all the seats were occupied I noticed that the driver's vision was not obstructed by the front passenger.

There was sufficient leg room to the two seats to avoid cramp, but the angle of the backs was not comfortable for a long journey. On the driver's side of the cab there is ample space for comfortable long-distance work.

In chassis and cab form the Condor weighed 3 tons 134 cwt. Allowing that the extended wheelbase, longer frame, special cab and Metallic tyres accounted for 34 cwt., the standard 13-ft. 6-in, wheelbase model should weigh approximately 31 tons. When equipped with a platform body, the payload rating of the standard vehicle is 8 tons solo or 6-7 tons when pulling a 4-ton trailer.

Concrete blocks, representing

a 71-ton payload and platform body, were carried, making a gross weight, with crew, of II tons. I collected the chassis from the Croydon works and after filling the 'fuel tank to overflowing point, started the journey to Warrington. Avoiding the morning traffic in London, 1 made a detour by the South and North Circular roads, making fair headway apart frOm occasional periods when fog was encountered.

The sequence of gear-lever positions in the gate seemed at first to be awkward, and as this was my first test of a Meadows engine, I needed' time to become accustomed to its characteristics. My first impressions were good. It pulled well at moderate speeds and was smoothrunning. With automatic advance and retard of the fuel-injection point, operation at low speed was quiet and steady, and at the top end of the governed range the performance was lively.

It took two hours to cover the first 40 miles, but when the fog lifted and less traffic was encountered, I soon found that the Condor could keep pace with the fast medium-range commercial traffic. After testing the brakes and finding that there was adequate power I drove without reserve.

The brake pedals on other types in the Motor Traction range are light in action, but the linkage in the Condor has been adjusted and more effort from the driver is required. At first this tended to give an impression of insufficient braking power, but experience proved that there was adequate retardation if the pedal was pressed hard enough.

After driving for three hours I stopped for half an hour's break. The 100-mile mark was reached in 4 hrs. 5 mins., and up to this point second gear had been used only once when baulked on a long gradient.

The Condor maintained a steady 45 m.p.h. on reasonably level ground, but direct drive was brought into use when inclines reduced speed to 30 m.p.h.

The vehicle has ideal ratios for overseas, where there is no speed limit, but for general trunk haulage in Britain a lower-ratio axle might be preferred. This would probably give greater economy of fuel by improving hill-climbing performance.

Between Dunstable and the Rugby wireless station the gradients were generally favourable and, driving fast, the average speed between these two points was over 30 m.p.h. During the next 65 miles, to Stoke, there

were numerous hills and heavy traffic which cramped the style and this section took 2 hrs. 40 mins., which is equal to an average speed of 28 m.p.h.

After another break at Stoke I continued the final stage of the consumption test to Warrington and with reasonable traffic conditions covered 34 miles to the North Cheshire Motors depot in 1 hr. 10 mins. Altogether I had been driving for 7 hrs. 55 mins., which gives an average speed of 25.2 m.p.h. for the entire journey.

When refuelling, 169 gallons were required to fill the tank, affording a fuel-consumption rate of 12.1 m.p.g., which, considering the speed, is a good Average figure. Had the Road Haulage Executive's schedule of 16.6 m.p.h been maintained for the journey, the fuel-consumption rate a4 would have been improved, probably reaching 16-18 m.p.g. and, with a lower axle ratio of 7.67 to 1, economy might have been even greater.

, The engine was comparable with a six-cylindered unit for smooth running and, apart from induction noise, was .relatively quiet. No driver could complain of the steering or driving positions, but I 'would prefer the gear lever to be cranked forward for more comfortable manipulation.

There was no overheating in the cab. I have previously noted the cool operation of Rutland vehicles and the Condor is no exception, because under normal driving conditions the radiator-water temperature ranged from 145 to 155 degrees F., and after climbing for 31 mins. in third gear it reached'170 degrees F., with a day temperature of 43 degrees F. Intelligent use of a radiator blind might improve fuel consumption.

Vision ahead and to the sides was good and the quick-drop windows facilitated signalling. The lighting was adequate for fast night driving and the centrally mounted speedometer was easily distinguished without distracting attention from the road.

The short performance and hillclimbing tests were conducted in the Warrington and Northwich areas, and there the Condor showed its paces by accelerating from rest to 20 m.p.h. in under 20 secs. and reached 30 m.p.h. in 43.4 secs.

Its braking characteristics were about average for the 12-ton-gross class, with stopping distances of 30 ft. from 20 m.p.h. and 66-70 ft. from 30 m.p.h. Hill-climbing performance, having regard to the axle ratio, was good and light work was made of the steep gradients from the Bull Ring in Northwich, and of the long Bamton Hill from the I.C.I. works. The steepest gradient locally was the short, but sharp, Acton Cliff, which has a maximum incline of I in 61, and here, in a stop-start trial, the lowest ratio was employed for the first time.

Although the vehicle is geared for fast long-distance work, there is an alternative direct-drive gearbox available for tipping-lorry operation or for use in hilly areas. The overdrive gearbox makes for comfortable driving at 30-35 m.p.h., but if the legal maximum speed is to be regarded, it would be more practical to employ the lower-ratio axle so as to obtain better top-end torque characteristics of the engine.