Passing Comments

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Transport Engineers Essential

'TAKING place on the first night of the great fog, a few of the 350 members and guests of the Institute of Road Transport Engineers were unable to attend its annual dinner-dance. Mr. Harold Elliott, chief traffic officer of the Road Haulage Executive and formerly general manager of Pickfords, Ltd., responded for "The Guests," proposed by the president, Mr. G. Mackenzie Junner.

Mr. Elliott said he was an operator and as such could not satisfy customers without the assistance of the engineering side of the industry. Those in road transport deserved more sympathy; transport was A24 taken too much for granted. It was institutions like the I.R.T.E. which gave the industry the most help. All the operators asked for was that the engineers should give them the efficiency standard of the RollsRoyce without bothering about gold stars!

The president referred to the many friends that the Institute had made. It was itself a remarkably friendly body and had brought into the lives of many, opportunities of co-operation and camaraderie formerly missing.

Mr. Kenneth Home proposed the toast of the chairman and referred to the remarkable growth of the Institute.

Cross-member Used for Oil

TN the design of its twin-axled bogie, R. A. Dyson land Co., Ltd., has eliminated many wearing parts, there being no spring shackles or spring bolts. The two tubular high-tensile-steel axles are connected by two inverted laminated springs • with their ends clamped in rubber-lined boxes. The trunnions at the spring centres are lubricated under a slight gravity head by two flexible hoses supplied from a tubular cross-member which is partly filled with oil.

Expedient Becomes Practice

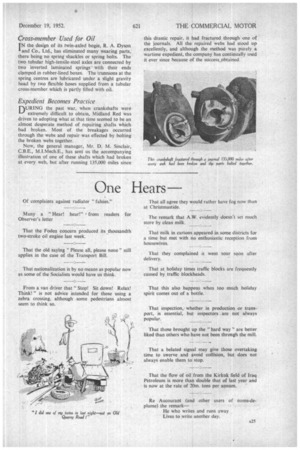

DURING the past war, when crankshafts were

extremely difficult to obtain, Midland Red was driven to adopting what at that time seemed to be an almost desperate method of repairing shafts which had broken. Most of the breakages occurred through the webs and repair was effected by bolting the broken webs together.

Now, the general manager, Mr. D. M. Sinclair, C.B.E., M.I.Mech.E., has sent us the accompanying illustration of one of these shafts which had broken at every web, but after running 135,000 miles since this drastic repair, it had fractured through one of the journals. All the repaired webs had stood up excellently, and although the method was purely a wartime expedient, the company has continually used it ever since because of the success obtained.