Unorthodox Features in Engine Design

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

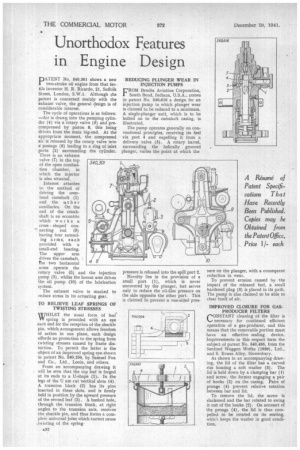

PA T EN T No. 640,301 shows a new two-stroke oil engine from that fertile inventor H. R. Ricardo, 21, Suffolk Street, London, S.W.1. Although the patent is concerned mainly with the exhaust valve, the general design is of considerable interest.

The cycle of operations is as follows: —Air is drawn into the pumping cylinder (4) via a rotary valve (5) and precompressed by piston 8, this being driven from the main big-end. At the appropriate moment, the compressed air is released by the rotary valve into a passage (6) leading to a ring of inlet ports (2) surrounding the cylinder. There is an exhaust

valve (7) in the top of of the open mbu tion chamber, in which the injector is also situated.

Interest attaches to the method of driving the overhead camshaft (1) and the fa ther auxiliaries. On the end of the crankshaft is an eccentric which works a cross shaped con' necting rod (9) having four extending arms, each provided with a small-end bearing. The upper arm drives the camshaft, the two horizontal arms operate the rotary valve (5) and the injection pump (3), whilst the lowest arm drives the oil pump (10) of the lubrication system.

The exhaust valve is masked to reduce stress in its actuating gear.

TO RELIEVE LEAF SPRINGS OF TWISTING STRESSES

vf /1-1 1 LST the usual form of leaf. VV spring is provided with an eye each end for the reception of the shackle pin, which arrangement allows freedom of action in one plane, such design affords no protection to the spring from twisting stresses caused by frame distortion. To permit the latter is the object of an improved spring eye shown in patent No, 540,194, by Samuel Fox and Co., Ltd., Leeds, and others.

From an accompanying drawing it will be seen that the top leaf is forged at its ends to a U-shape (1). In the legs of the U are cut vertical slots (4). A trunnion block (2) has its pins inserted in these slots, and is firmly held in position by the upward pressure of the second leaf (3). A bushed hole, through the trunnion block, at right angles to the trunnion axis, receives the shackle pin, and thus forms a complete universal joint which cannot cause , twisting of the spring REDUCING PLUNGER WEAR IN INJECTION PUMPS

FROM Bendix Aviation Corporation, South Bend, Indiana. U.S.A., comes in patent No. 540,616 a design for an Injection pump in which plunger wear is claimed to be reduced to a minimum. A single-plunger unit, which is to be bolted on to the camshaft casing, is illustrated.

The pump operates generally on conventional principles, receiving its fuel via port 4 and expelling it from a delivery valve (5). A rotary barrel, surrounding the helically grooved plunger, varies the point at which the sure on the plunger, with a consequent reduction in wear.

To prevent erosion caused by the impact of the released fuel, a small hardened plug (3) is placed in its path. The pump is also claimed to be able to clear itself of air.

IMPROVED CLOSURE FOR GASPRODUCER FILTERS

CONSTANT cleaning of the filter is necessary for continued efficient operation of a gas-producer, and this means that the removable portion must have an effective sealing device. Improvements in this respect form the subject of patent No. 540,495, from the Sentinel Waggon Works (1936), Ltd., and S. Evans Alley, Shrewsbury.

As shown in an accompanying drawing, the lid of the filter has a curved rim housing a soft washer (3). The lid is held down by a clamping bar (1) and screw, the former engaging a pair of hooks (2) on the casing. Pairs of prongs (4) prevent relative rotation between bar and lid.

To remove the lid, the screw is slackened and the bar rotated to swing it out of the hooks (2). On account of the prongs (4), the lid is thus compelled to be rotated on its seating, whic'i keeps the washer in good condition.