HINTS ON MAINTENANCE.

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to

CONTRIBUTIONS are invited for this page from fleet, managers, drivers, garage foremen, and mechanics, works staff and draughtsmen, and will be paid for on a generous scale. Every system, make, and type of commercia,1 motor vehicle will be dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle—practices

Secure Reliability and to Avoid Trouble.

which,, whilst they may he quite normal, are peculiar to the particular vehicle and may not be generally known to those responsible for its running. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, dealing with letters from our driver and mechanic readers. Communications should be addressed to " The Editor, The Commercial Motor, 7-15, Rosebery Avenue, London, E.

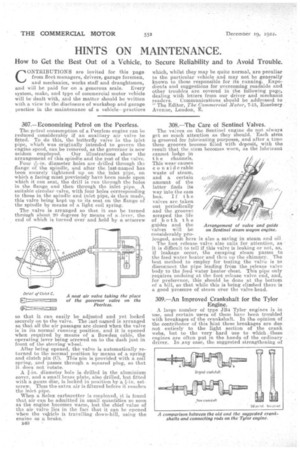

307.—Economizing Petrol on the Peerless. The petrol consumption of a Peerless engine can be reduced considerably if an auxiliary air valve be fitted. To do this, the butterfly valve in the iplet pipe, which was originally intended to govern the engine speed, can be removed, as the governor is now seldom employed. Our illustrations show the arrangement of this spindle and the rest of the valve. Four diameter holes are drilled through the flange of the spindle, and after the last-named has been securely tightened up on the inlet pipe, on which a facing must previously have been made upon which it can seat, the drill is run through the holes in the flange and then through the inlet pipe. A suitable circular valve, with four holes corresponding to those in the spindle and inlet pipe, -is then made, this valve being kept up to its seat on the flange of the spindle by means of a light coil spring. The valve is arranged so that it can be turned thrciugh about 20 degrees by means of a .lever, the end of which is turned over and held by a setscrew so that it can easily be adjusted and yet locked securely on to the valve. The last-na,med is arranged so that all the air passages are closed when the valve is in its normal running position, and it is opened when required by means of a Bowden cable, the operating lever being screwed on to the dash just in front of the steering wheel. After being opened, the valve is automatically returned to the normal position by means of a spring and clutch pin (C). This pin is provided with a coil spring, .and passes through a squared plug, so that it does not rotate.

A 2.-in. diameter hole is drilled in the aluminium cover, and a small brass plate, also drilled, but fitted with a gauze disc, is locked in position by a i-in. setscrew. Thus the extra air is filtered before it reaches the inlet pipe. When a Solex carburetter is employed, it is found that air can be admitted in small quantities so soon as the engine becomes warm, but the chief value of the, air valve • lies in the fact that it can be opened when the vellicIe is travelling down-hill, using the engine as a brake.

n40

308.—The Care of Sentinel Valves. The valves on the Sentinel engine do not always get so much attention as they should. Each stem is grooved for lubricating purposes, and after a time these grooves become filled with deposit, with the result that the stem becomes worn, as the lubricant cannot lodge in t h e channels. This wear causes considerable waste of steam, and a certain amount of the latter finds its way into the earn box. If the valves are taken out periodically and the grooves scraped the life of both the guides and the valves will be considerably pro longed, an& here is also a saving in steam and oil. The foot release valve also calls for attention, as it is difficult to tell if this valve is leaking or not, as, if leakage occur, the escaping steam passes to the feed water heater and then up the chimney. The best method to employ for testing the valve is to disconnect the pipe leading from the releas.e valve body to the feed water heater chest. This pipe only requires undoing at the foot release valve end, and, for preference, this should be done at the bottom of a hill, so that while this is being climbed there is a good pressure of steam over the valve-head.

• ,/

A

Arrangement of valve and guide on Sentinel steam wagon engine.

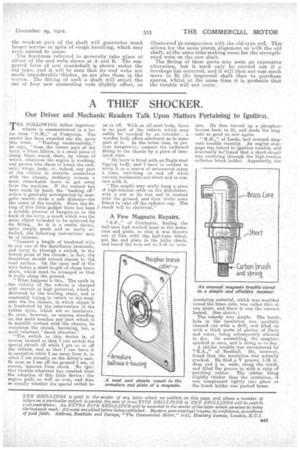

309.—An Improved Crankshaft for the Tylor

• Engine.

A large number of type JB4 Tyler engines is in use, and certain users of them have been troubled with breakages of the crankshaft. In the opinion of the contributor of this hint these breakages are due not entirely to the light section of the crank webs, but to the very hard use to which , these engines are often put in the hands of the ordinary driver. In „any case, the suggested strengthening of

the weakest part of the shaft will _guarantee much longer service in spite of rough handling, which may even extend to abuse.

The fractures referred to generally take place at either of the end webs shown at A and B. The suggested form of new crankshaft is shown under the old type, and it will he seen that its:end webs are made considerably'thicker, as are also those in the centre.: The fitting of such a shaft will entail the use of four new connecting rods slightly offset, as illustrated in.comparison with the old-type rod. This allows for the same piston alignment as with the old shaft, at the same time making room for the strengthened webs on the new shaft.

The fitting of these parts may seem an expensive alteration, but it needonly be carried out if a breakage has occurred, and it will then not cost much more to fit the improved shaft than to purchase spares, whilst at the same time it is probable that the trouble will not recur.