THE SIX-WHEELER WI] UR DRIVEN WHEELS.

Page 18

Page 19

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

DURING a recent, visit to the works of the Four Wheel Drive Lorry Co., Ltd., whose head office is at 44-46, Kingsw ay, London, W.C. 2, we w ere interested to note the great progress which has been made in the organization of the works for the really satisfactory and thorough rebuilding of F.W.D. vehicles • and the production of new types. The works manager is Mr. C. F. Cleaver, A.M.I.C.E., M.I.A.E., who is also a director of the company. Mr. Cleaver appears to be a genius at the work which he has undertaken. The stores, shops, and offices are all laid out so that each step in the production of a vehicle can be followed minutely, both by those. who superintend tho work and even by the casual visitor.

The rebuilding of the large numbers of used vehicles which have been bought up by the company has been brought to a fine art, and no weaknesses could possibly escape observation. The body of each vehicle is removed, the chassis cleaned down, the engine and gearbox lifted out, and the springs and axles taken off. After this, the engineand gearbox and other units are completely stripped, the engine parts washed in a soda bath, and the gearbox and axle parts cleaned with paraffin. The cylinder water-jackets are tested hydraulically to 25 lb. pressure, and complete sets of parts are then sent to the gangs dealing with the different units. Meanwhile, the frame goes to the smithy, where it is carefully tested for loose rivets, the existence of cracks, etc., . after which it is thoroughly cleaned down and painted. All fitting is done as carefully as in the erection of new vehicles. Any defective parts are relegated to the scrap-heap, for the company have enormous stocks of new parts on which to draw, and the resulting product is, in every way, as satisfactory as a new vehicle and bears a six months' guarantee of a most comprehensive nature. A large proportion of the sales is to meet repeat orders—a sure indication of what users think of the rebuilt machines.

Great attention is paid to the matter of service after the vehicle is sold, and requests for spare parts are attended to with the utmost expedition, every part being replaceable from stock. When reassembling the vehicle, as a rule, the original -engine and other units go into the frame, this being chiefly for the mike of the records, although, as a matter of fact, units and frames have proved to be interchangeable.

All the springs are stripped and greased, and if necessary set up, and, in cases where the chassis is required to carry a tipping body, the springs are suitably reinforced.

The company have not remained content with the mere production of rebuilt vehicles, and they are now engaged in converting the standard F.W.D. chassis into different types of vehicles for specific uses.

Pritnarily, we would mention the F.W.D.-BartleWatson six-wheeled tractor-lorry to carry 8-10 tons. This should make a most satisfactory combination owing to the four-wheel-drive principle utilized in the F.W.D. vehicle, which should assist materially in the efficient transport of such heavy loads. In fact, the builders consider that it will not be long before four-wheel-drive will be applied to a larger number of tractor-lorries.

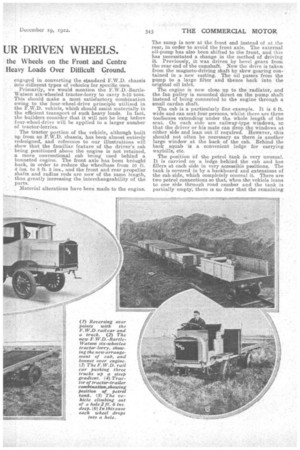

• The tractor portion of the vehicle, although built up from an F.W.D. chassis, has been almost entirely redesigned, and reference to our illustrations will show that the familiar feature of the driver's cab being positioned above the engine is not retained, a more conventional cab being used behind a bonneted engine. The front axle has been brought back, in order to reduce the wheelbase from 10 ft. 4 ins. to 8 ft. 5 ins., and the front and rear propeller shafts and radius rods are now of the Same. length, thus greatly increasing the interchangeability of the parts.

Material alterations have been made to the engine.

The sump is now at the front end instead of at the rear, in order to avoid the front axle. The external oil-pump has also been shifted to the front, and this has necessitated a change in the method of driving it. Previously, it was driven by bevel gears from the rear end of the camshaft. Now the drive is taken from the magneto-driving shaft by skew gearing con• tained in a new casting. The oil passes from the pump to a large filter and thence back into the original oil inlet.

The engine is now close up to the radiator, and the fan pulley is mounted direct on the pump shaft instead of being connected to the engine through a small cardan shaft.

The cab is a particularly fine example. It is 6 ft. wide and can seat four persons, whilst there are three toolboxes extending under the whole length of the seat. On oach side are railway-type windows, so that the driver or his mate can drop the windows at either side and lean out if required. However, this should not often be necessary as there is another large window at the back of the cab. Behind the back squab is a convenient ledge for carrying waybills, etc.

The position of the petrol tank is very unusual. It is carried on a ledge behind the cab and has fillers at each side in very accessible positions. The tank is covered in by a backboard and extensions of the cabside, which completely conceal it. There are two petrol connections so that, when the vehicle leans to one side through road camber and the tank is partially empty, there is no fear that the remaining

petrol will not be able to flow to the carburetter. The capacity of the tank is 35 gallons, and to prevent rattling and damage by vibration it rests on ten strips of thick felt.

The centre toolbox under the seat has a false bottom so that access to the gearbox can easily he obtained through the space provided by its removal. Arrangements have been made by which more power is exerted on the trailer brakes than on those acting on the centre pair of wheels. This is to -prevent the throwing forward of the weight of the load when both brakes are suddenly applied during an emergency. The company are also building an overtype model with an 8--ft. 5-in, wheelbase, instead of the present 10 ft. 4 ins. In this vehicle the 'steering is mounted, forward and the driver is seated beside the engine. This vehicle is designed particularly for municipal work, where the small turning circle will prove a considerable advantage.

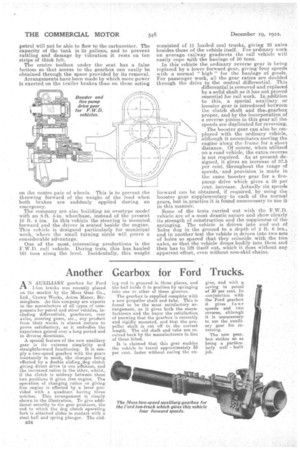

One of the most, interesting productions is the F.W.D. rail vehicle. During tests, this has hauled 161 tons along the level. Incidentally, this weight consisted of 11 loaded coal trucks, giving 22 axles besides those of the vehicle itself. For ordinary work on average railway gradients the rail vehicle will easily cope with the haulage of 50 tons.

In this vehicle the ordinary reverse gear is being replaced by a lower forward gear, giving four speeds with a normal " high " for the haulage of goods. For passenger work, all the gear ratios are doubled through the drive to the central differential: This differential is removed and replaced by a solid shaft as it has not proved essential for rail work. In addition to this, a special auxiliary or booster gear is introduced between the clutch shaft and the. gearbox proper, and by the incorporation of a reverse pinion in this gear all the speeds are duplicated for reversing.

The booster gear can also be employed with the ordinary vehicle, although it necessitates moving the engine along the frame for a short distance. Of course, when utilised on a road vehicle, the extra reverse is not required. As at present designed, it gives an increase of 37.5 per cent, throughout the range of speeds, and provision is made in the same bdoster gear for a firepump drive which gives a 50 per cent, increase. Actually six speeds forward can be obtained, if required, by using the booster gear supplementary to each of the normal gears, but ia practice it is found unnecessary to Use itin this manner.

Some of the tests carried out with the F.W.D. vehicle are of a most drastic nature and show clearly its strength of construction and the suppleness of the springing. The vehicle is driven into and out of holes dug in the ground to a depth of 2 ft, 6 ins., and in another test the vehicle is driyen into two sets of holes so spaced that they coincide with the two axles, so that the vehicle drops bodily into them and then has to lift itself out, which it does without any apparent effort, even without non-skid -chains.