Barker barking

Page 56

Page 57

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

he right tree

ONE haulage activity which appears to be suffering less than most from the trade recession is the reefer business.

Once a predominantly seasonal traffic, the transport of perishable foodstuffs has been revolutionised by the sophistication of quick-freezing processes and the subsequent increase in the number of cold stores in which foodstuffs and produce, formerly on the markets only for a limited period, can be stored indefinitely.

The controlled release of :traffic from these cold stores could, possibly, involve a number of opportunities to carry the same traffic, perhaps two or three times: imported frozen food from docks to cold stores; transport between cold stores throughout the country; conveyance from cold store to point of sale — and even back again, if prices do not reach anticipated levels.

No 'easy touch'

This is not to say that the reefer trade is an "easy touch" for the tyro. Investment in equipment is substantially higher than for the general haulage activity and the risks are that much greater.

The cost of a 40ft refrigerated box semi-trailer, already high, is increasing disproportionately and maintenance costs, increased by the need for careful maintenance of the refrigeration unit, are that much more onerous.

In addition, the standards already applied by some EEC member States for the international carriage of perishable foodstuffs (APT), and being considered for adoption by the UK, could add further costly factors to the vehicle specification. One of these could be the addition of a thermograph which records the temperature inside the box, throughout the journey, rather like a tachograph.

The hazards of late or non-delivery are further increased because some contracts for the carriage of frozen food, particularly meat, involve financial penalty clauses.

Running reefers is, therefore, essentially a specialist business built on confidence between cold store owners and vehicle operators and dependent on the expertise that established frozen food transporters bring to their operation.

One company which has been growing in stature for the past 14 or 15 years is Geort Barker Ltd.

Very much a family firm, Barker was based originally South London but moved to

'resent Barking depot several ears ago. Specialising in the -ansport of frozen meat, the rm operates 12 tractive units latched with about 28

refrigerated semi-trailers between 26ft and 40ft in length.

The tractive unit fleet is of mixed manufacture. Though nearly all have Gardner engines — the firm made a point of specifying these engines until recently — the latest acquisition is a Seddon-Atkinson with a Cummins power unit. This has been performing with great satisfaction and recording an economical fuel consumption now that it has been run in.

As for the trailer fleet, the smaller units are gradually being phased out in favour of the 40ft box to give greater flexibility. Most of the trailers are fitted with Thermo King refrigeration units, but as a matter of policy, the Hubbard diesel-electric unit is being preferred for the future.

Maintenance

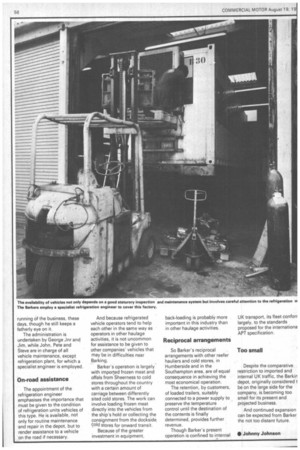

The company's administration and much of its maintenance function is divided between five of the brothers of the Barker family; George Barker Snr is less active in the running of the business, these days, though he still keeps a fatherly eye on it.

The administration is undertaken by George Jnr and Jim, while John, Pete and Steve are in charge of all vehicle maintenance, except refrigeration plant, for which a specialist engineer is employed.

On-road assistance

The appointment of the refrigeration engineer emphasises the importance that must be given to the condition of refrigeration units vehicles of this type. He is available, not only for routine maintenance and repair in the depot, but to render assistance to a vehicle on the road if necessary. And because refrigerated vehicle operators tend to help each other in the same way as operators in other haulage activities, it is not uncommon for assistance to be given to other companies' vehicles that may be in difficulties near Barking.

Barker's operation is largely with imported frozen meat and offals from Sheerness to cold stores throughout the country with a certain amount of carriage between differently sited cold stores. The work can involve loading frozen meat directly into the vehicles from the ship's hold or collecting the consignment from the dockside cold stores for onward transit.

Because of the greater investment in equipment, back-loading is probably more important in this industry than in other haulage activities.

Reciprocal arrangements

So Barker's reciprocal arrangements with other reefer hauliers and cold stores, in Humberside and in the Southampton area, are of equal consequence in achieving the most economical operation.

The retention, by customers, of loaded trailers, suitably connected to a power supply to preserve the temperature control until the destination of the contents is finally determined, provides further revenue.

Though Barker's present operation is confined to internal UK transport, its fleet conforr largely, to the standards proposed for the internationa APT specification.

Too small

Despite the comparative restriction to imported and internal UK traffic, the Barkir depot, originally considered t be on the large side for the company, is becoming too small for its present and projected business.

And continued expansion can be expected from Barker the not too distant future • Johnny Johnson