The

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

owl food' guide

THE regulation principally concerned with refrigerated transport in Europe is ATP — "Agreement on the International Carriage of Perishable Foodstuffs and on the Special Equipment to be used for Such Carriage."

The agreement defines the temperatures at which various foodstuffs. should be carried and the standards for the transport (special equipment) to be used on international traffic.

The UK is in the process of drafting the regulation to implement the agreement, and November is the target date for publication. However, the Government does not intend to implement the agreement for traffic wholly within the UK, in the foreseeable future. The possibility of introduction, here, cannot be completely ruled out, but it is not envisaged at present.

Even if such legislation was passed, it would take years to be introduced, and would probably not be retrospectively applied.

Signatory countries

The agreement means that anyone intending to transport perishable foodstuffs between signatory countries must have vehicles that meet the standards set in the agreement. Six countries have, so far, ratified: Denmark, France, Germany (West), Spain, USSR and Yugoslavia. All other member States in the _EEC intend to accede and the agreement is open to all members of the ECE who are not EEC members.

The standards for the vehicles are in two main parts, both of which must be met. The first relates to the construction of the vehicle body. The agreement allows two ,standards for this. The first is designated

ie "Normally insulated equipment,met by insulated construction equivalent to an overall K coefficient for the body of 0.6 Kcal / hour / rn2/ degrees C, or better. This coefficient is a measure of how the overall construction is achieved and includes losses from all sources which add up to an overall heat leakage of the vehicle body. The figure is then divided by the mean surface area of the body so a K coefficient is calculated which must meet the standard already mentioned. The second standard of vehicle body construction is defined as "IR" "Heavily insulated equipment" and the K coefficient for this type is 0.35 Kcal/hour/ rn'/ degrees C or better.

Careful construction The vehicle body built to meet IN standard needs to be carefully constructed; but it does not need thick insulation of the type normally used by leading insulated vehicle bodybuilders who usually use top quality polyurethane. If polystyrene or other lower grades of insulation are used, thicker insulation must be fitted to compensate for the lower thermal efficiency of. the material.

To meet the standard, careful construction, coupled with thicker insulation, must be employed. Again, using polyurethane as the material and assuming a vehicle body that includes all the usual attendant features — rear and /or side doors, meat rails, cargo restraint track, ventilator flaps, scuff rails, etc — a thickness of 75 to 100mm (3in to 4in) insulation, all round, would achieve the standard.

All these features, and more, must be taken into account when assessing vehicle design, because if they are to perform their functions properly, constructors must, inevitably, impinge on the efficiency of pure insulation.

Bodybuilder's skill

The skill of the specialist insulated and refrigerated bodybuilder lies in keeping these losses, to an absolute minimum consistent with producing a tough vehicle that will have a Icing trouble-free life.

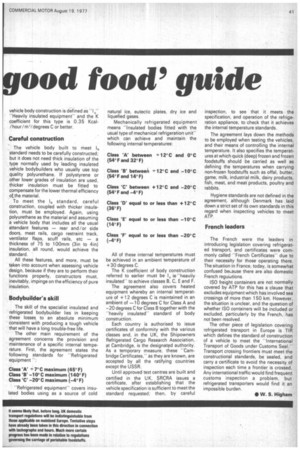

The other main requirement of the agreement concerns the provision and maintenance of a specific internal temperature. First, the agreement states the following standards for "Refrigerated equipment

Class 'A' -47°C maximum (45° F) Class 'B' —10°C maximum (140°F) Class 'C' —20°C maximum (-4° F)

"Refrigerated equipment" covers insulated bodies using as a source of cold natural ice, eutectic plates, dry ice and liquefied gases.

Mechanically refrigerated equipment means "Insulated bodies fitted with the usual type of mechanical refrigeration unit" which can achieve and maintain the following internal temperatures:

Class 'A' between -412°C and 0°C (54° F and 32°F)

Class 'B' between ± 12°C and —10° C (54°F and 14°F) Class 'C' between +12°C and —20°C (54° F and —4° F) Class 'D' equal to or less than + 12°C (36° F) Class 'E' equal to or less than —10°C (14° F) Class 'F" equal to or less than —20° C (-4° F) All of these internal temperatures must be achieved in an ambient temperature of +30 degrees C.

The K coefficient of body construction referred to earlier must be I, ie "heavily insulated" to achieve classes B, C, E and F.

The agreement also covers heated equipment whereby an internal temperature of +12 degrees C is maintained in an ambient of —10 degrees C for Class A and —20 degrees C for Class B together with the "heavily insulated" standard of body construction.

Each country is authorised to issue certificates of conformity with the various classes and, in the UK, the Shipowners Refrigerated Cargo Research Association, at Cambridge, is the designated authority. As a temporary measure, these "Cambridge Certificates," as they are known, are accepted by all the ratifying countries except the USSR.

Until approved test centres are built and certified in the UK, SRCRA issues a certificate, after establishing that the vehicle specification is sufficient to meet the standard requested; then, by careful inspection, to see that it meets the specification, and operation of the refrigeration appliance, to check that it achieves the internal temperature standards.

The agreement lays down the methods to be employed when testing the vehicles, and their means of controlling the internal temperature. It also specifies the temperatures at which quick (deep) frozen and frozen foodstuffs should be carried as well as defining the temperatures when carrying non-frozen foodstuffs such as offal, butter, game, milk, industrial milk, dairy products, fish, meat, and meat products, poultry and rabbits.

Hygiene standards are not defined in the agreement, although Denmark has laid down a strict set of its own standards in this regard when inspecting vehicles to meet ATP.

French leaders

The French were the leaders in introducing legislation covering refrigerated transport, and certificates were commonly called "French Certificates" due to their necessity for those operating there. The situation in France, today, is somewhat confused beLause there are also domestic French reguidtions.

ISO freight containers are not normally covered by ATP for this has a clause that excludes equipment which has involved sea crossings of more than 150 km. However, the situation is unclear, and the question of whether ISO containers will be included or excluded, particularly by the French, has not been resolved.

The other piece of legislation covering refrigerated transport in Europe is TIR which defines the standard of construction of a vehicle to meet the "International Transport of Goods under Customs Seal." Transport crossing frontiers must meet the constructional standards, be sealed, and carry a certificate to avoid the necessity of inspection each time a frontier is crossed. Any international traffic would find frequent customs inspection a problem, but refrigerated transporters would find it an impossible burden.

• W. S. Higham