Anti-knock Combustion

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

A CCORDING to patent No. 838,326, I—I pre-detonation in an engine cylinder can be reduced by injecting a small quantity of heated gas, accelerated to supersonic speeds, into the compressed main charge. The patent describes a way of doing this. (A. Meyer, Rocky River, Ohio, U.S.A.)

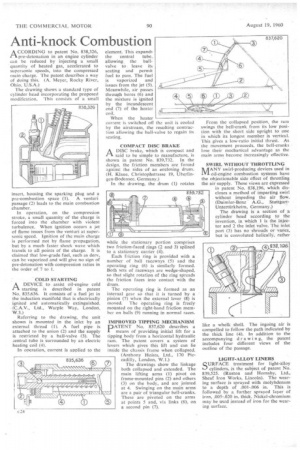

The drawing shows a standard type of cylinder head incorporating the proposed modification. This consists of a small insert, housing the sparking plug and a pre-combustion space (1). A venturi passage (2) leads to the main combustion chamber.

In operation, on the compression stroke, a small quantity of the charge is forced into the chamber with violent turbulence. When ignition occurs a jet of flame issues from the venturi at supersonic speed. Ignition of the main charge is performed not by flame propagation, but by a much faster shock wave which travels to all points of the charge. It is claimed that low-grade fuel, such as derv, can be vaporized and will give no sign of pre-detonation with compression ratios in the order of 7 to 1.

COLD STARTING

A DEVICE to assist oil-enginecold /-1 starting is described in patent No. 835,636. It consists of a fuel jet in the induction manifold that is electrically ignited and automatically extinguished. (C.A.V., Ltd., Warple Way, London, W.3.)

Referring to the drawing, the unit shown is mounted in the inlet by an external thread (1). A fuel pipe is attached to the union (2) and the supply is restricted by a ball-valve (3). The entral tube is surrounded by an electric heating coil (4).

In operation, current is applied to the element, This expands

the central tube, allowing the ballvalve to leave its seating and permit fuel to pass. The fuel is vaporized and issues from the jet (5). Meanwhile, air passes through bores (6) and the mixture is, ignited by the incandescent end (7) of the heater coil.

When the heater current is switched off the unit is cooled by the airstream, the resulting contraction allowing the ball-valve to regain its seating.

COMPACT DISC BRAKE

ADISC brake, which is compact and said to be simple to manufacture, is shown in patent No. 839,732. In the design. the friction members are forced against the sides of an enclosing drum. (H. Matte. Christophstrasse 19, Merlingen-Bodensee. Germany.)

In the drawing, the drum (1) rotates while the stationary portion comprises two friction-faced rings (2 and 3) spliried to a stationary carrier (4).

Each friction ring is provided with a number of ball raceways (5) and the operating ring (6) is similarly formed. Both sets of raceways are wedge-shaped, so that slight rotation of the ring spreads the friction faces into contact with the drum.

The operating ring is formed as an internal gear so that it is turned by a pinion (7) when the external lever (8) is moved. The operating ring is freely mounted on the right-hand friction member on balls (9) running in normal races.

IMPROVED TIPPING MECHANISM

PATENT No. 837,620 describes a means of providing initial lift for a tipping body from a horizontal hydraulic ram. The patent covers a system of levers which gives this lift and can lie inside the chassis frame when collapsed.

(Anthony Hoists, Ltd., 170 Piecadilly, London, W.1.) The drawings show the linkage both collapsed and extended. The main lifting arms (1) pivot on frame-mounted pins (2) and others (3) on the body, and are jointed at 4. Swinging on the main arms are a pair of triangular bell-cranks. These are pivoted on the arms at points 5 and, via links (6), on a second pin (7).

From the collapsed position, the ram swings the bell-crank from its low position with the short side upright to one in which its longest member is vertical. This gives a low-ratio initial thrust. As the movement proceeds, the bell-cranks • lose their mechanical advantage as the main arms become increasingly effective.

SWIRL WITHOUT THROTTLING

Jf ANY swirl-producing devices used in Lla oil-engine combustion systems have the objectionable side effect of throttling the air supply. These views are expressed in patent No. 838,196, which discloses a method of imparting swirl without impeding the air flow. (Daimler-Benz A.G., StuttgartUnterttirkheim, Germany.) The drawing is a section of -a cylinder head according to the invention, in which 1 is the injector and 2 the inlet valve. The inlet port (3) has no shrouds or vanes, but is convoluted helically, rather

like a whelk shell. The ingoing air is compelled to follow the path indicated by the thick line (4). In addition to the accompanying drawin g, the patent includes four different views of the outline of the passage.

LIGHT-ALLOY LINERS

SURFACE treatment for light-alloy cylinders, is the subject of patent No. 839,525. (Ruston and Hornsby, Ltd., Sheaf Iron Works, Lincoln). The wearing surface is sprayed with molybdenum to a depth of .001-006 in. This is followed by a further sprayed layer of iron, .005-.020 in. thick. Nickel-chromium may be used instead of iron for the wearing surface.