Don't Be FRIGHTENED By BIG JOBS

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

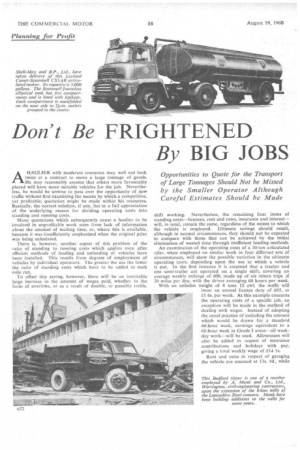

Opportunities to Quote for the Transport of Large Tonnages Should Not be Missed by the Smaller Operator Although Careful Estimates Should be Made

AHAULIER with moderate resources may well not look twice at a contract to move a large tonnage of goods. He may reasonably assume that others more favourably placed will have more suitable vehicles for the job. Nevertheless, he would be unwise to pass over the opportunity of new traffic without first examining the means by which a competitive, yet profitable, quotation might be made within his resources. Basically, the correct solution, if any, lies in a full appreciation of the underlying reason for dividing operating costs into standing and running costs.

Many quotations which subsequently cause a haulier to be involved in unprofitable work stem from lack of information about the amount of waiting time, or, where this is available, because it was insufficiently emphasized when the original price was being calculated.

There is, however, another aspect of this problem of the ratio of standing to running costs which applies even after efficient methods of loading and unloading of vehicles have been installed. This results from degrees of employment of vehicles by individual operators. The greater the use the lower the ratio of standing costs which have to be added to each mile run.

To offset this saving, however, there will be an inevitable large increase in the amount of wages paid, whether in the form of overtime. or as a result of double, or possible treble,

shift working. Nevertheless, the remaining four items of standing costs—licences, rent and rates, insurance and interest-will, in total, remain the same, regardless of the extent to which the vehicle is employed. Ultimate savings should result, although in normal circumstances, they should not be expected to compare with those that can be achieved by the initial elimination of wasted time through inefficient loading methods.

An examination of the operating costs of a 10-ton articulated oiler, when employed on similar work in four different sets of circumstances, will show the possible variation in the ultimate operating costs, depending upon the use to which a vehicle is put. In the first instance it is assumed that a tractor and one semi-trailer are operated on a single shift, covering an average weekly mileage of 600, made up of six return trips if 20 miles per day, with the driver averaging 60 hours per week.

With an unladen weight of 4 tons 12 cwt. the outfit will incur an annual licence duty of f65, or El 6s. per week. As this example concerns the operating costs of a specific job, an exception will be made in the method of dealing with wages. Instead of adopting the usual practice of including the amount which would be drawn for a standard 44-hour week, earnings equivalent to a 60-hour week in Grade I areas—all week'day work—will be used. Allowances will also be added in respect of insurance contrihations and holidays with pay, giving a total weekly wage of £14 Is.

Rent and rates in respect of garaging the vehicle are assessed at 13s. 4d., while

the annual premium for vehicle insurance is reckoned at £62 2s., or £1 4s. 10d. per week. Interest charged at a nominal rate of 3 per cent, on the initial outlay of £2,312 adds a further £1 7s. 9d., making the total for these five items of standing cost £18 12s. 11d. At 600 miles per week the standing cost per mile would be 7.46d.

With the rate of fuel consumption averaging 11 m.p.g., fuel cost per mile would amount to 4.2541., assuming that oil fuel was purchased in bulk at 3s. 10101, per gallon. Lubricants are estimated at 0.2741. per mile. With a set of tyres costing £289, and an estimated life of 30,000 miles, tyre costs per mile would amount to 2.0841. Maintenance is reckoned at 2.58d. per mile.

Depreciation is calculated by first deducting the cost of the initial set of tyres from the price of the vehicle, with a further deduction for loss on resale, a slightly higher percentage value being allowed in respect of the semi-trailer. Assuming a mileage life of 150,000 for the outfit, depreciation cost per mile would amount to 2.4841. Total running costs would be 11.66d. per mile and total operating costs 19.12d. With an average weekly mileage of 600, the operating cost per week would be £47 15s, 11d.

Working Double Shifts

Now assume that the outfit is engaged on similar work, but on double shift, resulting in an average weekly mileage of 1.200. Wages will be the only item of standing cost to be increased; they will be doubled and will total £28 2s. This would result in a total standing cost per week on double-shift working of £32 13s. lid., or 6.54d. per mile.

Four items of running costs—fuel, lubricants, tyres and depreciation—will remain the same for the second shift. There would, however, be a slight reduction in respect of maintenance, because it would be reasonable to assume that some of the minor servicing tasks, as well as washing, would be performed on a time, rather than a mileage, basis.

The total running cost per mile. when 1,200 miles per week are averaged, will he reckoned at 11.55d. and the total operating cost at 18.09d. The total operating cost per week of 1,200 miles would be £90 8s. 11d.

Although I have assumed throughout this example that efficient methods of handling at both ends have eliminated unnecessary loading delays, greater utilization could probably be obtained by employing one or more snare semi-trailers to each tractor unit. Whilst one additional semi-trailer would confer substantial benefits, particularly for long-distance work, maximum advantage on shuttle-service working, such as is envisaged here, could be obtained only by having a spare semi-trailer at both terminals, plus a third semi-trailer coupled to the vehicle en route.

Let us apply these circumstances to single-shift working.

With an average cost of £750 per additional semi-trailer, the total capital outlay will be £3,812. There should be no variation in the unladen weight, or the resulting licence duty. Wages will also be assumed to remain the same, despite the addition of two further trips per day resulting from the substantial reduction in turn-round time at both terminals.

Rent and rates will be nominally increased to £1 6s. 8d., whilst there will also be a slight addition to the weekly cost of insurance, bringing this amount to £1 12s. Because of the additional outlay, the interest charge now becomes £2 5s. 8d., giving a total standing cost per week of £20 its. 4d. The extra trips will raise the average weekly mileage per single shift to 800, resulting in a standing cost per mile of 6.17d.

Running costs will be similar to those previously given, although slight additions will be made to the items of maintenance and depreciation. Theoretically, the total mileage of all three semi-trailers would be the same as that of a single semi-trailer in the first example. But because of the additional coupling and uncoupling, extra maintenance will probably be required. Also, because of the greater outlay, depreciation will be slightly increased, to 2.53d., giving a total running cost per mile of 11.96d.

Tractor With Three Units

When the 10-ton tractor unit was operated with three semitrailers, and averaged 800 miles per week, the total operating cost would be 18.13c1. per mile, or £60 8s. 8d. per week.

Applying the same variations, as before, to double-shift working the total standing costs per week, inclusive of two men's wages, would be £34 12s. 441., or 5.19d. per mile. Total running costs would be slightly lower at 11.85d. per mile, resulting in a total operating cost per mile of 17.04d. When averaging 1,600 miles for the double shift, the total operating cost per week would he £113 12s.

To draw a comparison of the effect of these variations in operating costs, it will be assumed that the vehicle is working between buffer depots, carrying 10 tons per trip in one direction only. Where only one semi-trailer was employed and 30 trips per shift per week were made, the total tonnage carried per week would be 300. As the total operating cost per week in this instance is 147 16s., the resulting cost per ton would be 3s. 2i41. When two shifts were worked, but still with only one semi-trailer, 600 tons per week would be moved at a cost of £90 8s. 11d., or 3s. 03d. per ton.

The employment of three semi-trailers permits eight trips per day per shift to be worked, the equivalent of 400 tons per week. At a weekly cost of £60 8s. 8d., this again gives

a rate per ton of 3s. 04.d. When vehicle and three semitrailers are employed on double shift, 800 tons per week are moved at a cost of 1113 12s., or 2s. 10d. per ton.

The significance of these calculations lies in the extent of variation between the various tonnage rates rather than in the amounts, because they have been derived from a notional set of conditions. Application of the same principle of calculation to actual conditions would naturally result in differing rates per ton being obtained, but the ratio of variation would probably be found to be comparable.

In specific instances, consideration would also have to be given to the alternative; of extended overtime or shift working. S. B. c21