Unit Construction

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

Brought

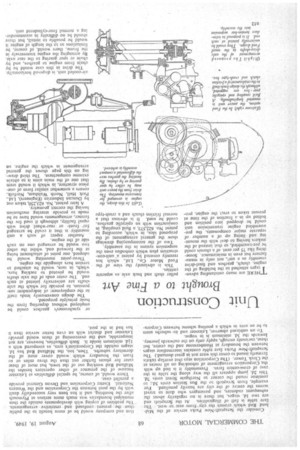

to a Fine Art TTHERE are many outstanding advantages attached to the building of the engine, clutch, gearbox and final-drive assembly as a unit, not only in manufacture hut even in maintenance. Something like 75 per cent. of a chassis could he pre-assembled, so that instead of the makers having to deal with the mounting and lining up of a number -of separate major components, the preassemble(' engine transmission unit could be dropped into position and bolted up in a fraction of the time at present taken to erect the engine, pro

peller shaft and back axle as separate entities, This is obviously the view of the Ford Motor Co., Ltd., which has recently covered by patent a' unit-con • struction plan which embodies even the suspension system in the assembly.

Two of the accompanying drawings show the general arrangement of the proposed idea, in which, according to patent No. 622,579, a fluid coupling, in conjunction with an epicyclic gearbox. could be used. It is obvious that a normal friction clutch and a crash-type or synchromesh gearbox could be employed without departing from the basic principle proposed.

The design conveniently lends itself to the employment of independent suspension, to provide for which the axle shafts are universally jointed at each end. The outer ends of the axle shafts would be pivoted to rocking bars. which, in turn, would be attached to torsion bars alongside the engine.

Three-point mounting would be adopted, one point of attachment being at the forward end, whilst the other two would be arranged one on each side of the engine.

Another aspect of such a unit assembly is that it could be arranged forfrontor -rear-wheel drive with equal facility, although it used for the. former, arrangements would have to be made to provide steering mechanism having the correct geometry.

A later patent, No. 623,250, taken out by Duncan Industries (Engineers), Ltd., Park Hall, North Walsham, Norfolk, covers a somewhat similar form of onepiece structure, in which it would seem that one of the main aims is to obtain extreme compactness. The third drawing on this page shows the general arrangement in which the engine, an air-cooled unit, is disposed horizontally.

The drive in this case would be by chain from engine to gearbox, and by chain or spur gearing w the rear axle. By arranging the engine transversely in the frame, there would, of course, be limitations as to the length of engine it would be possible to install, but there should be no difficulty in accommodating a normal four-cylindered unit.