The

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

Morris -Commercial 1-tonner

Fully Described

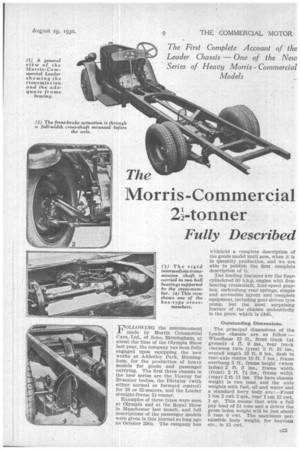

VIOLLOWING the announcement

made by Morris Commercial Cars, Ltd., of Soho, Birmingham, at about the time of the Olympia Show last year, the company has been fully engaged upon equipping the new works at Adderley Park, Birmingham, for the production of heavy models for goods and passenger carrying. The first three chassis in the new series are the Viceroy for 20-seater bodies, the Dictator (with either normal or forward control) for 28 or 32-seaters, and the Leader straight-frame 2i-tonner.

Examples of these types were seen at Olympia and at the Royal Show in Manchester last month, and full descriptions of the passenger models were given in this journal so long ago as October 29th. The company has withheld a complete description of the goods model until now, when it is in quantity production, and we are able to publish the first complete description of it.

The leading features are the fourcylindered 60 b.h.p. engine with fivebearing crankshaft, four-speed gearbox, unclerslung rear springs, simple and accessible layout and complete equipment, including gear-driven tyre pump, but the most surprising feature of the chassis undoubtedly is the price, which is £445.

Outstanding Dimensions.

The principal dimensions of the Leader chassis are as follow :— Wheelbase 13 ft., front track (at ground) 4 it 9 ins., rear track (between twin tyres) 5 ft. 3i ins., overall length 19 ft. 6 ins., dash to rear-axle centre 10 ft. 7 ins.; frame overhang 5 ft., frame height (when laden) 2 ft. 3 ins., frame width (front) 2 ft. 7i ins., frame width (rear) 2 ft. 11 ins. The bare chassis weight is two tons, and the axle weights with fuel, oil and water and a standard lorry body are :—Front 1 ton 2 cwt. 2 qrs., rear 1 ton 12 cwt. 1 qr. This means that with a full pay load of 2i, tons and a driver the gross laden weight will be just about 5 tons 6 cwt. The maximum permissible body weight, for boxvans etc., is 15 cwt.

The frame is of the pressed-steel channel-sectioned type, reinforced longitudinally at the rear, the main members being straight in elevation and parallel in plan. Their maximum depth is 64 ins., the flange width being 24 ins, The employment Df steel pressings, which is a marked feature throughout the machine, is particularly noticeable in the case of the transverse bracings, there being two box-type' cross-members opposite the anchorages for the rear springs, another pressed-steel cross-member in the overhang, and one carrying the rigid centre bearing of the propeller shaft.

In addition, there is a stout tubular member supporting the front end of the engine-gearbox unit, the rear end of which-is fixed to the frame members at two points, rubber buffers being interposed. The engine front mounting is of the trunnion type.

Good Springing a Feature.

The front springs are semi-elliptic and of very slight camber ; they are mounted under the frame members and shackled at the rear considerably lower than the front spring eyes. Their length is 3 ft. 24 ins. and their width 24 ins., and each comprises nine leaves 4 in. thick. The rear springs are mounted on stout brackets fixed to extensions of the pressed-steel cross-members, the axle case being underslung. The rear-spring length is 4 ft. 8 ins., and the width 24 ins., each spring consisting of 16 leaves of silico-manganese steel in. thick.

Steel-disc wheels with detachable outer-rim flanges carry 32-in. by 3-in, pneumatic tyres, with twin tyres at the rear, and the spare wheel and tyre are carried in a sub-frame under the frame overhang.

. Turning now to the engine, this isa simply designed and well-built four-cylindered unit with a single casting of chrome-nickel iron for the cylinder block and the top of the crankcase, this carrying the five main journals, which are 24 ins. in diameter.

c26 We noticed that the crankshaft has hollow crankpins and that the webs are drilled diagonally, copper pipes being inserted to ensure a free flow of oil under centrifugal force, direct to the big-end bearings.

The cylinder bore is 95 mm. and' the stroke 125 ram., the capacity being 3,544 c.c. Silchrome-steel valves of the side-by-side type are fitted, and duralumin connecting rods are employed in conjunction with three-ring pistons of a hard aluminium alloy. The camshaft-driven gear pump delivers oil under pressure to all main bearings, and an Auto-Klean oil filter is accessibly located on the off side of the crankcase.

The front end of the engine is extremely neat, three helical gears being empleyed for the drive of the camshaft, .dynamo and magneto. The dynamo is of the Lucas 1AT' type and charges a 12-volt battery Of the same make having a 63-amp.-hour capacity. The fan is belt-driven, the fan pulley having an adjustable flange. The. fan shaft is extended and carries the water impeller.

The electric starter is mounted on the off side, its shaft projecting forward with a squared end, which is useful in the event of the Bendix pinion sticking; this engages with an externally toothed ring pressed on and bolted to the flywheel. An S.U. horizontal-type carburetter is standardized, this having a 35 mm. flange.

. The single-plate dry clutch has an aggregate friction area, taking both sides of the driven disc, of 131.6 sq. ins. The gearbox and clutch are housed in separate casings, these being mounted to form a unit with . the engine. The indirect gear ratios are: 1.79, 2.68 and 4.99 to 1 forward, and 4.03 to 1 reverse, and the gearchange lever is centrally located, being Of the ball-mounted selective type. For a vehicle of this type, likely to be overloaded in actual service, it is of interest to mention that the gearbox mainshaft has a diameter of 2. ins., the layshaft diameter being 24 ins. The constantmesh gears have a face width of in., the other gears being 1 in. wide.

Transmission Details.

The transmission is through a fabric-type universal joint and a solid shaft of 14 in. diameter and 184 ins, long, to a cross-pin-type

universal joint of Special design at the front end of a short steadying shaft carried rigidly in a massive cross-member. This intermediate shaft is 2 ins, in diameter and Si ins. long and is carried in a ball bearing at each end. Behind it is another cross-pin universal, from which the rear portion of the propeller shaft, which is a 3-in. tube, 4 ft. 9-116

long, extends to a similar universal joint before the overhead-worm axle.

The final-drive ratio is 29 to 4 or 7.25 to 1, the worm having a pitch diameter of 24 ins., and the worm wheel, which is 2 ins, wide, a. pitch diameter of 11 ins. The differential gear is of the four-star bevel-pinion type. The driving-axle case is of sturdy design and carries fully floating axle shafts 2 ft. 101 ins, long and 11 in. in diameter, these being of 100-ton steel. The rear-wheel hubs are mounted on ball and roller bearings: The torque and drive are, of course, taken by the rear springs.

As regards the steering, this is of the worm-and-worm-wheel type 1.;vitkr adjustable roller bearings, and it

affords a turning circle of approximately 60-ft. diameter.

The Braking Layout.

The brakes have Orthodox mechanical operation, the pedal actuating expanding shoes in drums on all wheels, and the hand lever operating separate shoes in the rear drums. The front drums are 15 ins. and the rear drums 17 ins, in diameter, the front-brake shoes_ being 11 in. in effective width, whilst in the rear drums the hand-operated shoes are 1i in. and the foot-operated shoes 1i in. in width. • The foot-brake system provides an aggregate friction area of 208 sq. ins. and the hand-brake system 97 sq. ins.; thus a total brake-friction area of 305 sq. ins. is available, this amounting to 57.5 sq. ins, per ton of gross laden weight. Considering that the drums are of good thickness and diameter, the braking should be quite satisfactory, although, of course, we have not carried out exhaustive road tests in this respect.

Actuation of the front brakes is through the medium of a full-width cross-shaft carried before the axle, a lever at each end of this shaft pressing upon a similar lever on the short camshaft, which, of course, is universally jointed. Chassis lubrication is on the grouped-nipple system, a special feature being the lubrication for the cross-pin universal joints. These are made in halves and incorporate peripheral oil channels by which the lubricant is flung around to the four bearings. This strikes us as being of sound design and likely to give long life and satisfaction in service, We referred earlier on to the free use of pressed steel in the construction of this chassis, and would mention that the dashboard is a nickelsteel pressing, as is the instrument board. A particularly good feature in connection with the latter is that by undoing two screws and disconnecting the oil-gauge pipe, it can be hinged downwards to give access to the wiring at the back, the pivotin point being where a pressed-ste( support is fixed to a cross-tub( which acts as a strengthener for th pressed-Steel petrol-tank support.

Good Road Speed Possible.

We hope, a little later on, to b publishing a road-test report in cor nection with this chassis, and, in th

meantime, would conclude by sayiru that it appears to be a straightfor ward and simple machine calculate( to give the minimum of problems b users. The engine has an output o. 1.5 • b.h.p. per cwt. of bare chassii weight, or 0.566 b.h.p. per cwt. o gross laden weight. This meam that with a full load road speed; of 45 m.p.h. should be possible.