For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

Lamps Alight.

On Saturday, August 23rd, light your lamps at 9.7 in London, 9.30 in Edinburgh, 9.21 in Newcastle, 9.24 in Liverpool, 9.15 in Birmingham, 9.17 in, Bristol, and 9.37 in Dublin.

Getting Home with a Loose Driving Wheel.

The sender of the following communication has been

awarded the 10s. prize this week.

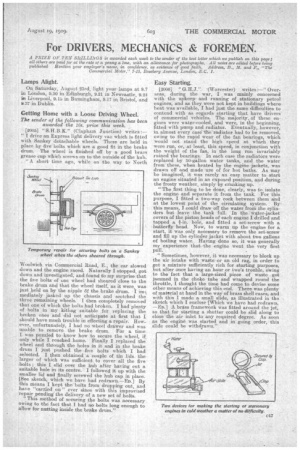

[2905] "S.H.B.K." (Clapham Junction) writes :— " I drive an Express light delivery van which is fitted , with Sankey detachable wheels. •These are held in place by ...five bolts which are a good fit in the brake drum. The wheel is finished off by a good brass grease cup which screws on to the outside of the hub. "A short time ago, while on the way to North Woolwich via Commercial Road, E., the ear slowed down and the engine raced. Naturally I stopped, got down and investigated, and. found to my surprise that the five bolts of one wheel had sheared close to the brake drum and that the wheel itself, as it were, was just held on by the nipple df the brake drum. I

mediately jaeked up the chassis and scotched the three remaining wheels. I then completely removed that one of which the bolts had broken. I had plenty of bolts in my kitbag suitable for replacing the broken ones and did not anticipate at first that I should have much trouble in effecting a repair. However, unfortunately, I had no wheel drawer and was unable to remove the brake drum. FM' a time I was puzzled to know how to secure the wheel, if only while I reached home. Finally I replaced the wheel and through the holes in it and in the brake drum I just pushed the five bolts which I had .,selected. I then obtained a couple of tin lids_ the larger of which was sufficient to cover all the five bolts ; this I slid over the hub after having cut a suitable hole in its centre. I followed it up with the smaller lid and finally screwed the hub cap in place. [See sketch, which wa have had redrawn.—En.] By this means I kept the bolts from dropping out, and have "carried on" ever since with this improvised repair.pendinithe delivery of a new set of bolts.

This method of securing the bolts was necessary owing to the fact that I had no bolts long enough to allow for nutting inside the brake driim."

Easy Starting.

12006] " G. H. J. " .(Worcester) writes :—" Overseas, during the war, I was mainly concerned with the upkeep and running of stationary petrol engines, and as they were not kept in buildings where heat was available, I had just the same difficulties to contend with as regards starting that have drivers of commercial vehicles. The majority, of these engines were water-cooled, and were, in the beginning, fitted with pump and radiator. Eventually, however, in, almost every case the radiator had to be removed, owing to the rapid wear of the fan bearings, which would not stand the high speed at which they were run, or, atleast, this speed, in conjunction with the weight of the fan, in the long run invariably ruined the bearings. In each case the radiators were replaced by 50-gallon water tanks, and the water from these, when heated by the engine jackets, was drawn off and made use of for hot baths. As may be imagined, it was rarely an easy matter to start an engine situated in an exposed position, and during the frosty weather, simply by cranking up.

"The first thing to be done, clearly, was to isolate the engine and separate it from the tank. For this purpose, I fitted a two-way cock between them and at the lowest point of the circulating system. By this means, I could draw off the water from the cylinders but leave the tank full. In the water-jacket covers of the piston heads of each engine I drilled and tapped a fin, hole, and fitted a set-screw with a butterfly head. Now, to warm up the engine for a start, it was only necessary to remove the set-screw and fill up the cylinder jacket with about two gallons of boiling water. Having done so, it was generally my experience that the engine went the very first pull. •

"Sometimes, however, it was necessary to block up the air intake with waste or an old rag, in order to get a mixture sufficiently rich for starting purposes, but after once having an hour or two's trouble, owing to the fact that a large-sized piece of waste got jammed in the choke tube and wrapped round the throttle, I thought the time had come to devise some other means of achieving this end. There was plenty of material at hand in the way of brass shell cases, and with this I made a small slide, as illustrated in the sketch which I enclose [Which we have had redrawn. —ED.] A brass framework was fitted around the jet, so that for starting a shutter could be slid along to close the air inlet to any required degree. As soon as the engine was started and in going order, this slide could be withdrawn."