RETURN FUEL LINES POSER

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

While fuel flow is easy to measure with a meter, accurate on-vehicle diesel fuel consumption figures are difficult to obtain. No one knows more about this than John Soltau

• Any vehicle's average fuel consumption can be established quite easily over a month or so by recording fuel intake and distance travelled. Such long-term information clearly is of no use to an operator or manufacturer who wants to find out quickly the effect on fuel consumption of such variables as road conditions and driving style.

For that, a means of measuring precisely the small quantities of fuel used by a vehicle over short distances is required. Enter fuel flow meters.

Meters which can measure the volume of liquid passing through them to an accuracy of within 1.5 per cent of the true volume are widely available. You might conclude, therefore, that there would be few problems in using one of these meters to make an accurate, on-vehicle, fuel consumption measuring system. You would be wrong, especially where diesel-engined trucks and buses are concerned.

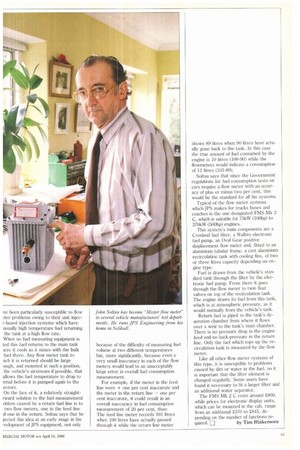

One man who is better qualified than any other we know to explain the many pitfalls liable to trap an unwary maker or user of fuel consumption measuring systems is John Soltau. A former chief engineer of Lucas's petrol injection division, Soltau set up his own development, design and instrumentation firm, JPS Engineering, in Solihull in 1974.

Now the list of names of users of JPS equipment is impressively long and includes organisations as diverse as Birds Eye Wall's and Moscow University. It is becoming increasingly common for CM road test vehicles, from car-derived vans to 38-tonners, to be supplied with fuel flow meters fitted and the name most likely to be on that equipment is JPS.

Soltau acknowledges that "to measure accurately fuel flow is relatively easy," whether the fuel is petrol or diesel. The challenge comes in doing so on diesel, petrol injection, and certain carburettor engines with return fuel lines without affecting engine performance.

"Lengthy tests carried out with vehicle manufacturers and research laboratories have shown that only one type of system can be accurate and leave the fuelling arrangements unchanged," says Soltau. This system consists of a pump which draws fuel from the vehicle's tank and delivers it via a flowmeter to a "relatively small tank/de-aerator with a float valve or valves which maintains a fixed fuel level.

"The tank/de-aerator is maintained at atmospheric pressure and the engine draws its fuel from it. Any return fuel is piped to an efficient de-aeration (de-gassing) chamber inside the tank. Provided this tank is fixed at the normal vehicle fuel tank height, the engine and its fuelling will be unaffected, so long as the fuel temperature is also kept normal. This can be achieved by finning the recirculation tank and, if necessary, by using an additional return line, ultra-low backpressure fuel cooler," he explains.

MAIN PROBLEMS

The two main problems facing any designer of a fuel consumption measuring system for compression ignition (diesel) engines are: 1 Not all the fuel pumped to the injectors is used immediately by the engine; a proportion of it is returned to the fuel tank via the leak-off or return line, and to add to the complication, this fuel is hotter than that in the feed line.

2 Diesel engines are sensitive to variations in the temperature and pressure of their fuel.

According to Soltau, the effects of fitting any fuel consumption measuring system which alters an engine's normal fuel pressure, either in the feed or return lines can be "startling, such as a 12 per cent drop in maximum power, and an increase in mid-range power with exhaust smoke or high exhaust emissions."

If the system has no adequate means, like a de-aeration tank, of allowing the butane gas which can build up in the return line to escape, then the result can be "fuel pump erosion and variable fuel injections," he warns.

There is no question that a variation in

temperature of the fuel at the injection pump will have an influence on fuel con sumption, simply because its volume varies with temperature. Indeed we ca remembers a certain simple fuel heater of a few years ago which was cheekily being marketed as a fuel-saving device, the fact that it also caused a lowering c engine power output being convenientl] ignored.

As several vehicle manufacturers har discovered, it is possible to fit a fuel cc sumption measuring system which will satisfactorily accurate when compared with tank top to tank top fills or with n ference flow measuring equipment, but which will give the vehicle significantly different fuel consumption figures from those that would be achieved if the equipment were not fitted.

Cummins and Detroit Diesel engines ve been particularly susceptible to flow !ter problems owing to their unit injecr-based injection systems which have usually high temperature fuel returning the tank at a high flow rate.

When no fuel measuring equipment is ted this fuel returns to the main tank iere it cools as it mixes with the bulk fuel there. Any flow meter tank to lich it is returned should be large Lough, and mounted in such a position, the vehicle's airstream if possible, that allows the fuel temperature to drop to ■ rmal before it is pumped again to the ectors.

On the face of it, a relatively straightrward solution to the fuel measurement oblem caused by a return fuel line is to two flow meters, one in the feed line d one in the return. So'tau says that he jected this idea at an early stage in his :velopment of JPS equipment, not only because of the difficulty of measuring fuel volume at two different temperatures but, more significantly, because even a very small inaccuracy in each of the flow meters would lead to an unacceptably large error in overall fuel consumption measurement.

For example, if the meter in the feed line were + one per cent inaccurate and the meter in the return line — one per cent inaccurate, it could result in an overall inaccuracy in fuel consumption measurement of 20 per cent, thus: The feed line meter records 101 litres when 100 litres have actually passed through it while the return line meter shows 89 litres when 90 litres have actually gone back to the tank. In this case the true amount of fuel consumed by the engine is 10 litres (100-90) while the flowmeters would indicate a consumption of 12 litres (101-89).

Soltau says that since the Government regulations for fuel consumption tests on cars require a flow meter with an accuracy of plus or minus two per cent, this would be the standard for all his systems.

Typical of the flow meter systems which JPS makes for trucks buses and coaches is the one designated FMS Mk 2 C, which is suitable for 75kW (106hp) to 370kW (500hp) engines.

This system's main components are a Crosland fuel filter, a Walbro electronic fuel pump, an Oval Gear positive displacement flow meter and, fitted to an aluminium tubular frame, a cast aluminium recirculation tank with cooling fins, of two or three litres capacity depending on engine type.

Fuel is drawn from the vehicle's standard tank through the filter by the electronic fuel pump. From there it goes through the flow meter to twin float valves on top of the recirculation tank. The engine draws its fuel from this tank, which is at atmospheric pressure, as it would normally from the vehicle's tank.

Return fuel is piped to the tank's deaeration chamber from where it flows over a weir to the tank's main chamber. There is no pressure drop in the engine feed and no back-pressure in the return line. Only the fuel which tops up the recirculation tank is measured by the flow meter.

Like all other flow meter systems of this type, it is susceptible to problems caused by dirt or water in the fuel, so it is important that the filter element is changed regularly. Some users have found it necessary to fit a larger filter and an additional water separator.

The FMS Mk 2 C costs around £800, while prices for electronic display units, which can be mounted in the cab, range from an additional £370 to £845, depending on the number of functions re quired. 0 by Tim Blakemore