F it a sliding fifth wheel and you immediately make your

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

tractive unit more versatile, reckons Mike Pinder, managing director of Eurohitch (UK). "Sliders currently account for 50% of our business," he says, "compared with a 70/30% split in favour of fixed fifth wheels a few years ago.

"Sales are dropping off a little, but that's because owner-drivers, who may have to haul a mixture of different trailers, don't seem to be in the market for new tractors at present," he adds. "They remain popular among rental fleets, though, and most rental companies take them."

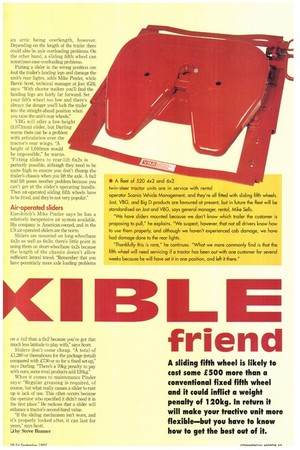

VBG sales manager Roger Darling says: "Distribution and haulage fleets running various different types of trailer favour them too, especially in the UK and Scandinavia— it's really a North European thing—and it's interesting to note that some of the oil companies are specifying two-position fifth wheels on their tractors. A slider allows an operator to cope with the short kingpins found on skeletals, the 1.6m pins found on standard triaxle trailers, and the 1.8m pins found on some older Continental trailers."

Last April VBG launched the modular 65SF sliding fifth wheel. A low-profile sliding channel allows the assembly to be bolted directly onto the tractor unit chassis with no need for a subframe.

One standard model can handle any mounting height with a simple change of fifth-wheel feet. Previous sliders had integral mounting feet, so a different model was needed for different heights. "It's been 15 years since we announced that we were going to make our fifth wheels integral with the slider," says Darling, "so it seems as though we've gone full circle."

The first operator to use the VBG 65SF sliding fifth wheel is Fergusons Transport of Sunderland, which runs 200 vehicles. Iveco Ford dealer North East Truck & Van's engineering operation fitted it to an Iveco Eurotech MF400E 381V/P mid-lift tractor.

Fergusons transports automotive parts between factories in Sunderland and Spain for Nissan, and for Ford and Rover within the UK. The company also delivers newsprint tlwoughout Britain for Metsa Serie of Sweden and UPM-Kimmene of Finland. The UK operations use high-cube trailers which are just under 4.9m tall.

North East Truck & Van technical and engineering director Norman Whittaker reckons the VBG coupling is 50kg lighter than some conventional models. VBG says that independent tests show that it's 35.5kg lighter than its closest main competitors with 57mm more travel. Its also lower.

However, a sliding fifth wheel must be used with caution, says Darling. Drivers must be carefully briefed on its use.

Operators who can predict which trailers they are likely to encounter sometimes paint white lines on the chassis as a guide. Others fit stops to ensure the slider can't be moved beyond a certain point (typically it can be slid 500mrn to 1,000nun). It makes sense to take advice from the chassis manufacturer on how much latitude can be allowed. "Depending on the trailer being pulled and the fifth wheel's positioning the balance of the unit can be affected," Darling explains. This can also have implications for its braking performance.

Drivers are often tempted to leave a slider in its rearmost position because they're worried about having a trailer bash the back of their cab, he continues This could result in

an artic being overlength, however. Depending on the length of the trailer there could also be axle overloading problems On the other hand, a sliding fifth wheel can sometimes ease overloading problems.

Putting a slider in the wrong position can foul the trailer's landing legs and damage the unit's rear lights, adds Mike Pinder, while Barrie Scott, technical manager at Jost (GB), says: "With shorter trailers you'll find the landing legs are fairly far forward. Set your fifth wheel too low and there's always the danger you'll lock the trailer into the straight-ahead position when you raise the unit's rear wheels."

VBG will offer a low-height (1,073mm) slider, but Darling warns there can be a problem with articulation over the tractor's rear wings. "A height of 1,040mm would be impossible," he warns. "Fitting sliders to rear-lift 6x2s is perfectly possible, although they need to be quite high to ensure you don't thump the trailer's chassis when you lift the axle. A 6x2 mid-lift poses another problem because you can't get at the slider's operating handle. Then air-operated sliding fifth wheels have to be fitted, and they're not very popular."

Eurohitch's Mike Pinder says he has a relatively inexpensive air system available. His company is American-owned, and in the US air-operated sliders are the norm.

Sliders are mounted on long-wheelbase 4x2s as well as 6x2s; there's little point in using them on short.wheelbase 4x2s because the length of the chassis doesn't allow sufficient lateral travel. "Remember that you have potentially more axle loading problems

on a 4x2 than a 6x2 because you've got that much less latitude to play with," says Scott.

Sliders don't come cheap. "A total of £1,280 or thereabouts for the package (retail) compared with £730 or so for a fixed set-up," says Darling. "There's a 70kg penalty to pay with ours, some rival products add 120kg."

When it comes to maintenance Pinder says: "Regular greasing is required, of course, but what really causes a slider to rust up is lack of use. This often occurs because the operator who specified it didn't need it in the first place." He reckons that a slider will enhance a tractor's second-hand value.

"If the sliding mechanism isn't worn, and it's properly looked after, it can last for years," says Scott.

0 by Steve Banner