American-type Semi-traill British Users

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

MORE than half of North American longdistance road haulage is carried out by articulated vehicles incorporating frameless semi-trailer vans. Now the York Trailer Co., Ltd., Corby, Northants, employing their experience of build

ing integrally constructed semi-trailer vans in Canada,

are producing units of this type for operation in Britain. To be known as the Freightmaster range, the vans are offered in body lengths of from 22 ft.-28 ft., heights

from 6 ft.-9 ft. and widths of 7 ft. 6 in. and 8 ft. They can be fitted with York singleor tandem-axle running gear, and, for export, body lengths up to 40 ft. may be supplied.

It is felt that there is an expanding market for semitrailers of this type here as York contend that the pattern of British road haulage is beginning to parallel the development which has taken place in North America during the past 15 years. There, the increasing production and carriage by road of friable consumer goods, such as washing machines, spindryers and television sets, coupled with more haulage of foodstuffs, have demanded large-capacity vehicles giving adequate load protection.

Wooden packing cases are being 'replaced by cardboard containers and articles so protected cannot be roped and sheeted down on an open vehicle. Therefore these commodities can be carried satisfactcirily only in an enclosed vehicle.

For the high speeds which will be permitted on the new motorways, sheeted vehicles are likely to run into trouble. A flapping tarpaulin at 30 m.p.h. is different from the same thing at 50 m.p.h., when it would probably tear itself to pieces while acting as a brake on the vehicle. The York Freightmaster range of semi trailer vans employs integral construction using a high proportion of light-alloy components to reduce weight. Construction is on the stressed-skin principle.

Many Advantages Thus the van has many advantages but the penalty which is incurred immediately with a bodied vehicle is the reduction in payload because of the increased unladen weight. Adoption of frameless design is intended to counteract this. A 27-ft.-long tandem axle Freightnaaster weighs 3 tons 15 cwt. complete to standard specification. This is only 9 cwt. more than the standard York flat platform vehicle, and probably about 10 cwt. less than a conventional van semi-trailer with a lightalloy body on a platform chassis.

This tow weight is achieved by making the side walls of the van body the main longitudinal load-carrying members for the structure, dispensing with the chassis side members employed in conventional construction. A large number of crossmembers is still employed, but these act merely as floor supports transferring the load directly into the body side panels which are designed on the stressed-skin principle.

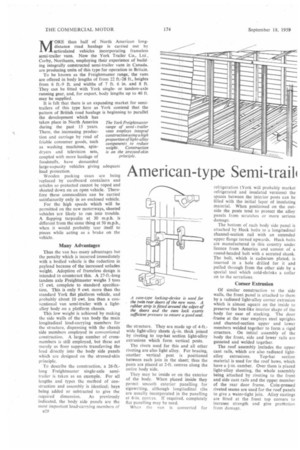

To describe the construction, a 26-ft.long Freightmaster single-axle semitrailer is taken as an example. For all lengths and types the method of construction and assembly is identical; bays being added or subtracted to give the required dimension. As previously indicated, the body side panels are the most important load-carrying members of B28 the structure. They are made up of 4-ft.

wide light-alloy sheets thick joined by riveting to top-bat section light-alloy extrusions which form vertical posts.

The rivets used for this and all other riveting are also light alloy. For bracing, another vertical post is positioned between each join in the sheet; thus the posts are placed at 2-ft. centres along the entire body side.

They may be inside or on the exterior of the body. When placed inside they permit smooth exterior panelling for signwriting, although longitudinal ribs are usually incorporated in the panelling at 6-in. centres. If required, completely flat panelling may be used.

When the van is converted for refrigeration (York will probably market refrigerated and insulated versions) the spaces between the interior posts can be filled with the initial layer of insulating material. When positioned on the outside the posts tend to protect the alloy panels from scratches or more serious damage.

The bottom of each body side panel is attached by Huck bolts to a longitudinal channel-section rail with an extended upper flange turned upwards. Huck bolts are manufactured in this country under licence from America and consist of a round-headed bolt with a serrated shank. The bolt, which is cadmium plated, is inserted in a hole drilled for it and pulled through from the other side by a special tool which cold-shrinks a collar on to the serrations.

Corner Extrusion Of similar construction to the side walls, the front panel is attached to them by a radiused light-alloy corner extrusion which is almost square on the inside to preserve the box-like interior shape of the body for ease of stacking. The door 'frame at the rear employs steel uprights and channel-section upper and lower members welded together to form a rigid structure. On initial assembly of the body the front, side and lower rails are gusseted and welded together.

The roof assembly includes the upper cant rails, which are also radiused lightalloy extrusions. Top-hat section material is used for the roof bows. which have a fin. camber. Over them is placed light-alloy sheeting, the whole assembly being attached by riveting to the front and side cant rails and the upper member of the rear door frame. Coin-pressed riveted seams are used for the roof panels to give a water-tight join. Alloy castings are fitted at the front top corners to increase strength and give protection from damage. the front of the upper body are is attached the pick-up plate ng thb king-pin for fifth-wheel trig. This is a welded fabrication i. thick steel plate incorporating two channel-section cross-members and

stiffening members of similar n. The rubbing plate extends ; almost the full width of the semi and is secured to the front and rails by huck bolts and high-tensile bolts.

,m the rear of the pick-up plate to :nd of the semi-trailer transverse supports are placed at approxiy 1-ft. centres, although there arc variations in this dimension to imodate the landing and running Moving rearwards, the first three members are made up of 4-in.-deep Lel section welded back-to-back to 1-section members. The fourth and cross-members are 1 ft. deep with York vertical-lift landing gear ed between them.

Bogie Sub-frame Le 8-in.-deep cross-members are :d between the rear landing-gear la and the 14-in, deep member to t the forward end of the sub-frame ie single-axle rear bogie is attached. >ogie sub-frame is made up of two .udinal channel-section members d to the 1-ft. 2-in.-deep cross:er and to another deep cross)er at the extreme rear of the te. Over the bogie are a further 4-in-deep cross-members.

:h cross-member is tapered at each to fit into the side rails and is led with welded-on flanges which against the rails and are Huck1 to them. The flanges of the crosser also are Huck-bolted to the • and lower flanges of the side rail. the standard specification semir, the cross-members are steel, but it is possible that for future special models they will be replaced by lightalloy components for further weight saving. Where steel and alloy are bolted together, priming and jointing compound is interposed to prevent electrolytic corrosion.

Diagonal stability for the structure is given by cross bracing between the pickup plate and the landing gear, and between the landing gear and the forward bogie mounting.

At the rear of the semi-trailer two posts dropped from the final crossmember -carry a bar parallel to and about 1 ft. from the road surface. This acts both as a step and as a barrier to prevent cars running under the rear. The standard floor is in wood of I in. nominal

thickness, but light-allay flooring can he provided if required.

The twin rear doors have light-gauge steel frames, panelled in light alloy. "flack opening is only 11 in. less in total than the interior cross section which is, in itself, only 31 in. less than the overall dimension. The interior length is 41 in. less than the outside measurement. The doors may be folded back against the body sides and are each mounted on three hinges. A rubber sealing strip is fitted around the door edges and a cam lever-type door lock exerts sufficient pressure to make a tight seal.

A side door can be fitted to the van. This has an opening of 3 ft, 6 in. and is slightly lower than the rear door to allow a deep upper frame to be incorporated to offset the effect of breaking the side panel. It has a flush handle in order to keep within the statutory overall width.

The basic 22-ft.-van with single-axle running gear costs £1,550. Each foot of extra length costs an additional £25, whilst choice of the tandem-axle bogie adds a further £650. York have a novel method of quoting cost of carrying capacity. Floor space in the single-axle van costs £1 1s. per sq. ft. and cubic capacity 6s. per cu. ft.