STOCK

Page 102

If you've noticed an error in this article please click here to report it so we can fix it.

IN TRAD

• Livestock carriers may be using foreignmade trucks but eight out of ten of them are more than satisfied with home-built bodywork.

It is true to say that many are impressed by designs from overseas but SO% are happy to continue buying UK-sourced vehicles.

Our latest survey of nearly 100 animal transporters reveals a contentment (not shared by every industry sector) that is largely self-generated.

Most of the hauliers that we spoke to run small fleets of no more than a handful of vehicles, nearly all of them with multidecking of varying types.

FRENCH FARMERS

Over half of the fleets comprise rigids, the remainder being mainly semi-trailers and drawbars, with a few containers thrown in. One quarter of those surveyed stick with just local work while nearly six out of ten operate UK-wide. The remainder are busy trading to the Continent and beyond, many of them running the gauntlet of French farmers.

Almost all of the operators interviewed are aware of BS 5750 and its implications but nearly half still take the traditionalist view and continue to work with bodybuilders with whom they have long standing relationships.

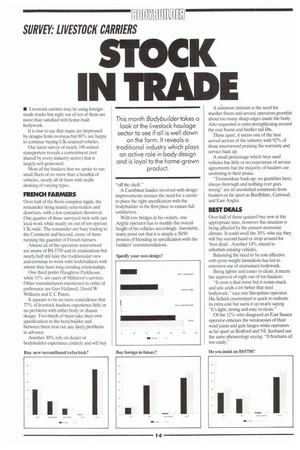

One third prefer Haughton Parkhouse while 15% are users of Millmoor's services. Other manufacturers mentioned in order of preference are Geo Halliwell, David W Williams and E C Paton.

It appears to be no mere coincidence that 77% of livestock hauliers experience little or no problems with either body or chassis design. Two-thirds of them take their own specificatiion to the bodybuilder and between them iron out any likely problems in advance.

Another 30% rely on dealer or bodybuilder experience entirely and will buy

-off the shelf."

A Cumbrian haulier involved with design improvements stresses the need for a carrier to place the right specification with the bodybuilder in the first place to ensure full satisfaction.

With low bridges in his vicinity, one Argyle operator has to modify the overall height of his vehicles accordingly. Inevitably, many point out that it is simply a 50/50 process of blending its specification with the builders' recommendations.

A co-mmon criticism is the need for sturdier floors and several operators grumble about too many sharp edges inside the body. Also requested is extra strengthening around the rear frame and beefier tail lifts.

These apart, it seems one of the best served sectors of the industry with 92% of those interviewed praising the warranty and service back up.

A small percentage which buys used vehicles has little or no experience of service agreements but the majority of hauliers are unstinting in their praise.

"Tremendous back-up; no grumbles here; always thorough and nothing ever goes wrong" are all unsolicited comments from hauliers as far apart as Banffshire, Cornwall and East Anglia.

BE DEALS

Over half of those quizzed buy new at the appropriate time, however this situation is being affected by the present economic climate. It could swell the 30% who say they will buy second hand or shop around for 'best deals'. Another 14% intend to refurbish existing vehicles.

Balancing the need to be cost effective with gross weight limitations has led to extensive use of aluminium bodywork.

Being lighter and easier to clean, it meets the approval of eight out of ten hauliers.

it costs a deal more but it resists muck and uric acids a lot better that steel bodywork," says one Shropshire operator. His Selkirk counterpart is quick to indicate its extra cost but sums it up neatly saying "It's light, strong and easy to clean."

Of the 12% who disagreed an East Sussex operator criticises the weaknesses of their weld joints and gate hinges while operators as far apart as Bedford and NE Scotland use the same phraseology saying: "It fractures all too easily."