DoE BLOCKBUSTER

Page 41

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

The Department has published a Reading University report arguing the case for allowing double bottoms on British roads. It is a document which could influence transport patterns all aver Europe in the next decade.

by John Darker AMBIM :N the run-up to the General Election he Department of the Environment )ublished a blockbuster of a report uhich could be immensely influential in ihaping the freight transport pattern of 3ritain and Europe in the next decade. Politicians of all parties agree that the :ountry's parlous economy demands ;ustained and intelligent thought to ivert unmentionable disasters. Since listribution efficiency is at least as mportant as industrial productivity, we nust hope that decision-makers study he arguments of Mr P. W. Reed and Vliss F. J. Rees so well deployed in 'Economic Potential of Long-Distance .oad Haulage: An Operational and -.7nvironmental Study", The Road Traffic Act 1974, yet to be implemented by Statutory Instrument, contains provisions which remove the effect of Section 65 of the Road Traffic Act 1972 (Restriction on number of trailers drawn). It is understood that these powers are to be transferred to the Motor Vehicles (Construction and Use) Regulations 1973 with the idea of regularizing the use of double bottoms on certain British roads.

Rail protest

The authors, orReading University, were commissioned by the DoE to examine the economic prospects for possible new types of vehicle and the modes of operating them in the light of associated environmental effects. At the outset the aim was to consider the case for relaxing the Construction and Use Regulations; in particular to examine the case for using double-trailer and double-bottom vehicles as well as other very heavy vehicles, all in the context of public — especially railway — investment decisions.

It is a near-certainty that the rail lobby as is their right — will splutter vehethent protests at the very thought of road trains and extensive marshalling yards abutting British motorways. It is paradoxical that developing road haulage technology, as evidenced by the massive increases in the use of double and treble-bottom outfits in America, has developed almost as a parallel concept, with railways. Indeed, if the authors had chosen to weave into their thesis some of the likely accompani ments of road-trains electronic gear for accurate station-keeping on motorways, even driver-less lorry-trains — the parallel would have been even more striking.

The present 32-ton-gross weight limit for heavy lorries engaged in general operations in Britain bears harshly on consignors and operators who would wish to carry heavier or more bulky loads. A socially optimal maximum vehicle capacity must balance operational convenience and economy with environmental considerations not always capable of assessment in money terms.

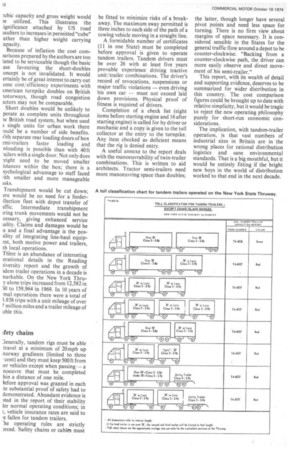

The authors believe that the vehicle types most worth testing are: 1. The "short-double" twin-trailer combination, restricted to "nominated" routes; 2. The "short-double" twin-trailer combination, not so restricted (though not necessarily permitted to operate on all roads); and 3. The "turnpike-double" twin-trailer combination, not only restricted to nominated routes but also subjected to elements of "track" and terminal control to some extent resembling those of a railway system.

Other developments such as a 44 tons gross single-semi-trailer and a 56 tons gross rigid plus drawbar combination are considered in the report, but its main stress is on doubles.

Interchange points

The authors were influenced by a 1970 Civic Trust Report "Heavy Lorries" which urged the possibility of interchange points outside town centres, where goods could be transferred from large lorries to smaller delivery Vans. The twin-trailer combination put forward by the Reading University study holds that this solution offers most of the benefits and few, if any, of the disadvantages associated with physical transhipment. There is little doubt that most road hauliers will agree, since transhipment involves such unwelcome cost and time penalties.

A "turnpike-double" in the United States consists of a tractive unit plus two semi-trailers forming a train 98 to 108 ft long. Such rigs are permitted and operated only on toll road/ systems. Combinations, consisting of two 40ft semi-trailers connected by a "dolly", and drawn by an ultra-powerful tractive unit, are assembled and broken up in marshalling yards close to junctions with State and Federal roads, upon which the big outfits are not allowed. One case was noted by the authors of the use of the hard shoulder for assembly but most marshalling yards appear to be any suitable level piece of land owned by or available to the turnpike authorities. No charge is made for use of marshalling areas. It might have been sensible for such areas to comprise extensive sites equipped with parking, warehousing, vehicle maintenance, refuelling, hotel accommodation and traffic exchange facilities, but in fact the authorities dis courage the use of yards for storage o maintenance and little development o facilities was envisaged when the repor was compiled over two years ago. Soml large haulage undertakings operatim turnpike dodbles have moved wholi depots to sites alongside the turnpikes so that they provide their own marshalling facilities.

There is little doubt that if what may be described as "transport trading estates" were sanctioned in Britain with access — perhaps via motorway service stations — , to motorways, that American-type double-bottom operations would be attractive to some operators.

For turnpike doubles to be economic in this country substantial traffic volumes would be necessary. There would be problems of operational flexibility in the making up of "trains" and the need to "balance-up" from each end of the transit. Keeping track of equipment, especially the driver and the dolly, would call for highly disciplined control procedures and realtime computers, or at least teletype systems, to monitor equipment.

Given operations spanning Europe, traffic controllers could doubtless learn initially from major container service operators, who have similar problems keeping track of "boxes" and ensuring containers are in the right place at the right time.

There are successful turnpike double operations in the USA over Britishlength mileages, although America is clearly better suited than Britain to deploy such equipment to the best advantage.

Given turnpike doubles where the individual semi-trailers each carry 20 tons, the authors imagine their use between Watford and seven other centres ranging from Birmingham (95 miles) to Glasgow (377 miles). Given favourable conditions costs are broadly in line with those of a 32-ton gcw single artic even for the 95-mile trip, though costs are appreciably higher given unfavourable circumstances.

Positive at 144 miles The authors say that turnpike doubles increase in advantage until this becomes positive at 144 miles (favourable) and at 227 miles (unfavourable). For practical purposes the break-even points are broadly 100 to 200 miles, depending on circumstances. Everything depends on the precise location of marshalling yards in relation to traffic origins and destinations. Costs are magnified with increased logistic/shunting mileage. Long distance "shuttle" trunk services between sites connected to motorways are another story.

Such large doubles, assuming a break-even point of 200 miles, would "tap" a substantial amount of traffic and would interest many specialist operators, particularly if the EEC countries allowed their widespread use on a unified motorway network.

Extensively used, such turnpike doubles would be obvious competitors of long-distance rail movements. The political difficulties in encouraging this development speak for themselves but quality of service factors, speed, reliability and control, could make road freight movement attractive even when costs exceed those by rail. Many American road freight services are significantly more expensive than rail, but they are well patronized. One turnpike double stage run in the United States of 440 miles is covered in 11 hours, including a 30-mile stretch of the relatively congested New Jersey highway, two refreshment stops and an unhooking in a marshalling yard. A 504mile trip is scheduled to take 12 hours, including stops, with one driver. Speed limits 55 mph on the New York Thruway — are strictly enforced. A more typical mileage per shift for a line-haul driver would be 300-350. Long-distance drivers in America are paid chiefly according to distance travelled, with time allowances for certain elements of the operation. The short-double twin-traile combinations range in length from 55 t 65ft with single trailers of 25-28f Compared with a 40 ft trailer (box) tt two shorter trailers of a 65ft rig provid a third more carrying capacity, 3,600 cuft against 2,700 cu ft. At th capacity, the present rnaximui permitted gross weight in America — c average, 32 tons can be achieved wil merchandise of little more than 12 lb pi cu ft.

Lightweight materials

There is a trend towards me chandise with a higher commodi bulk/ weight ratio. Some freight a most sensibly be carried on a 40ft trail but it appears the increasing use of HO weight materials for goods and packa ing -plastic, fibreglass, aluminitu expanded polystyrene, etc — h provided the main rationale for t short-twin trailer combination in Nor America. At the bulk/weight ral (1 cu ft: 17.51b) both trailers' potent :ubic capacity and gross weight would )e utilized. This illustrates the ignificance attached by US road iauliers to increases in permitted "cube" ather than higher weight carrying .apacity.

Because of inflation the cost comiarisons prepared by the authors are too Fated to be serviceable though the basic ase favouring the short-doubles oncept is not invalidated. It would ertainly be of great interest to carry out ome cost; efficiency experiments with ■ merican turnpike doubles on British iotorways, though road congestion ictors may not be comparable.

Short doubles would be unlikely to perate as complete units throughout le British road system, but when used s single units for urban work there rould be a number of side benefits. iith separate rear loading doors of box 2mi-trailers faster loading and nloading is possible than with 40 ft -ailers with a single door. Not only does -eight need to be moved smaller istances within the box; there is a sychological advantage to staff faced ,ith smaller and more manageable tsks.

Transhipment would be cut down; ere would be no need for a feederillection fleet with depot transfer of iffic. Intermediate transhipment [ring trunk movements would not be cessary, giving enhanced service Lality. Claims and damages would be is and a final advantage is the pos)ility of integrating line-haul equipmt, both motive power and trailers, th local operations.

There is an abundance of interesting erational details in the Reading iiversity report and the growth of idem trailer operations in a decade is narkable. On the New York Thruy alone trips increased from 12,582 in 50 to 159,964 in 1969. In 10 years of .mal operations there were a total of 5.938 trips with a unit mileage of over 7 million miles and a trailer mileage of able this.

Sety chains

Ilenerally, tandem rigs must be able travel at a minimum of 20 mph up itorway gradients (limited to three • cent) and they must keep 500 ft from [er vehicles except when passing — a noeuvre that must be completed hin a distance of one mile.

3efore approval was granted in each te substantial proof of safety had to demonstrated. Abundant evidence is )ted in the report of their stability ler normal operating conditions; in 1, vehicle insurance rates are said to 'e fallen for tandem trailers.

'he operating rules are strictly arced. Safety chains or cables must be fitted to minimize risks of a breakaway. The maximum sway permitted is three inches to each side of the path of a towing vehicle moving in a straight line.

A formidable number of certificates (11 in one State) must be completed before approval is given to operate tandem trailers. Tandem drivers must be over 26 with at least five years provable experience driving tractive unit trailer combinations. The driver's record of revocations, suspensions or major traffic violations — even driving his own car — must not exceed laid down provisions. Physical proof of fitness is required of drivers.

Completion of a check list (eight items before starting engine and 16 after starting engine) is called for by driver or mechanic and a copy is given to the toll collector at the entry to the turnpike. Any item checked as deficient means that the rig is denied entry.

A useful annexe to the report deals with the manoeuvrability of twin-trailer combinations. This is written to aid architects. Tractor semi-trailers need more manoeuvring space than doubles; the latter, though longer have several pivot points and need less space for turning. There is no firm view about margins of space necessary. It is considered sensible in the States for the general traffic flow around a depot to be counter-clockwise. "Backing from a counter-clockwise path, the driver can more easily observe and direct movement of his semi-trailer."

This report, with its wealth of detail and supporting evidence, deserves to be summarized for wider distribution in this country. The cost comparison figures could be brought up to date with relative simplicity, but it would be tragic to reject the new operating philosophy purely for short-run economic considerations.

The implication, with tandem-trailer operation, is that vast numbers of industrial sites in Britain are in the wrong places for rational distribution logistics and sane environmental standards. That is a big mouthful, but it would be entirely fitting if the bright new boys in the world of distribution worked to that end in the next decade.