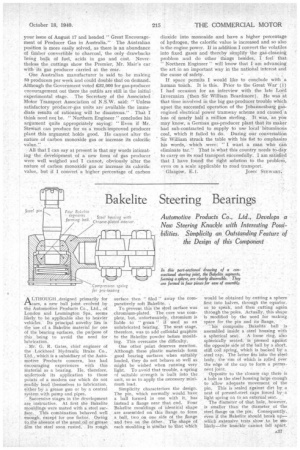

Bakelite Steering Bearings

Page 71

If you've noticed an error in this article please click here to report it so we can fix it.

Automotive Products Co., Ltd., Develops a New Steering Knuckle with Interesting Possibilities. Simplicity an Outstanding Feature of the Design of this Component

ALTHOUGH .designed primarily for . cars, a new ball joint evolved by the Automotive Products Co., Ltd„ of 1„pridon and Leamington Spa, seems likely to be applicable also, to heavier vehicles. Its principal novelty lies in the use cf a Bakelite material for one of the bearing surfaces, the purpose of this being to avoid the need for lubrication.

• Mr: G. R. Gates, chief engineer Of the -Lockheed Hydraulic Brake Co., Ltd., Which is a subsidiary of the Auto: motive Products concern, has had encouraging experiences with this Material as a bearing. He, therefore, undertook its application to those points of a modern car which do not readily lend 'themselves to lubrication, either by a grease gun or by a central system with pump and pipes.

Successive stages in the development are instriictive. At first the Bakelite mouldings were mated with a steel surface.. This combination behaved well enough, eXcept for one factor. Owing to the absence of the asuaA„oil ,Or grease film the steel soon rusted. its rough

surface then " filed " away the com

paratively soft Bakelite. •

To. prevent this the steel surface was chromiurnplated. The cure was complete, but, unfortunately, chromium is liable to " groan " if used as an unluhricated bearing:. The next stage therefore, was to add colloidal graphite -to the Bakelite powder before mould-. ing. This overcame the difficulty. One other point deserves mention. Although these plastic materials forth good bearing surfaces when suitably loaded, they do not behave sb well as might be wished when running Yery. light. To avoid that trouble, a spring of suitable strength is built into the unit, so as to apply the necessary minimum load.

Simplicity characterizes the design. The pin, which normally wOuld hava a ball formed in one with it, has instead a flange near that end. Four Bakelite mouldings of identical shape are assembled on this 'flange to form. a hall, two on one side of the flange and two on the ether, The shape of each inoUlding is •similar to that which

would be Obtained by cutting a sphere first into halves, through the equator, so to speak, and then cutting again ,through the poles. Actually, this shape is modified by the need for making. space for the pin and its flange.

-Ails composite . Bakelite • ball is assembled inside a steel housing with

a spherical seat. A loose ring, also spherically seated, is pressed against the opposite side of the ball by a Short, stiff coil spring„ which is backed by a steel cap. The latter fits into the steel body, the rim Of which is rolled over the •edge of the cap to form a permanent joint.

Opposite to the closure cap there is

hole in the steel housing large enough to allow adequate movement of the pin. This is sealed against dirt by a nest of pressed-steel caps. forced by: a light spring on to an external seat,

The diameter of that hole, hbwever, is smaller than the diameter. of 'the steel flange on the pin, Consequently, 'eVen if the Bakelite should break. up— which .extensive "tests show to be unlikelY—the knuckle cannot fall apart.