EQUIPMENT AND COMPONENTS

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

kDVANCE DESPITE THE WAR AT this time of the year, in normal circumstances, we would be getting worked up about the immediate prospect of a Show—in London or in Glasgow. Two years, practically, have now elapsed since there has been one. It is at these shows that progress is most manifest, that developments are disclosed, but the fact that there are no shows does not mean there is nothing new.

Truly, manufacturers have had little opportunity of research, experiment and all the rest that goes with departing from old practices and introducing improvements, and there must inevitably be less news of a technical nature than would otherwise be the cAse. Moreover, many developments, for obvious reasons, must be secret. However, let us investigate, with some semblance of method, the position as it applies to chassis equipment, seeking points of interest, new or old, as they may come to mind.

Convention commonly excludes the power unit from the class falling under the definition " equipment" and, for the purposes of the moment, we propose confining to it only proprietary parts and components.

Next in importance to the engine is the gearbox. A growing need for quietness, easy control and good performance, and the continued progress of the oil engine have led to a vigorous demand for five-speed gearboxes, As

an example of one such, coming from a leader in the fielo of gearing, we may name the David Brown, which is made ii sizes suitable, broadly, formaximum-load four,.six and eight wheelers, respectively. It differs from the orthodox tow speed box in having two pairs of constant-mesh wheel, (both with helical teeth). The driving pinion of the twit is, as usual, on the input-shaft, whilst the driven pinion of the second is free on the main shaft.

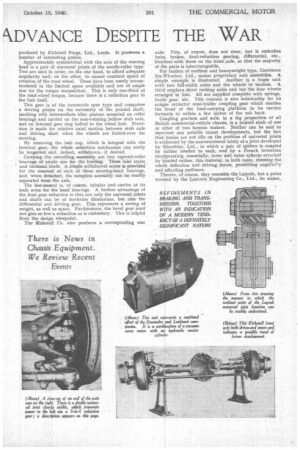

For the fifth ratio, which is an over drive, the latte pinion is engaged with its shaft by a sliding dog, the °the, side of which performs the function of giving direct drive (fourth gear). Otherwise, the layout is conventional. The unit is compact and gear changes can be easily made in customary manner, the six lever positions being fore and aft in every case for each of three lateral points. A worm-type final-drive unit is also a well-known product of David Brown and Sons (Huddersfield), Ltd., and an interesting point, in this connection, is that the practice of employing worm-drive for trolleybusesuniversal we believe in this country—is spreading overseas, this maker having supplied a considerable number for this purpose. Doubtless a feature that contributes much to the success of this unit is that it is self contained and the alignment of the moving parts in no way depends on the assembly of the axle. One of our pictures shows a dismantled unit, and from this the maker's patent form of thread and sturdy tooth shapes and proportions can be appreciated.

During the past few years there has been a definite trend towards four-wheel drive. It has, of course, been discernible more in connection with chassis built for operation on rough country or unmade roads than with those for use wholly on hard surfaces, but there seem to be indications that the movement may spread.

An example of a proprietary unit falling under the heading of this article is a front driving and steering axle produced by Kirkstall Forge, Ltd., Leeds. It possesses a number of interesting points.

Approximately symmetrical with the axis of the steering head is a pair of universal joints of the needle-roller type. Two are used in order, on the one hand, to afford adequate angularity and, on the other, to ensure constant speed of rotation of the road wheel. These have been neatly accommodated in the limited space available and are of ample size for the torque transmitted. This is only one-third of the road-wheel torque, because there is a reduction gear in the hub itself.

This gear is of the concentric spur type and comprises a driving pinion on the extremity of the jointed shaft, meshing with intermediate idler pinions mounted on roller bearings and carried on the non-rotating hollow stub axle, and an internal gear ring bolted to the wheel hub. Provision is made for relative axial motion between stub axle and driving shaft when the wheels are locked-over for steering.

By removing the hub cap, which is integral with the internal gear, the whole reduction mechanism can easily be insgected and, indeed, withdrawn,. if desired, Carrying the swivelling assembly are two tapered-roller bearings of ample size for the loading. These take static and torsional loads. A simple withdrawal screw is provided for the removal of each of these steering-head bearings, and, when detached, the complete assembly can be readily separated from the axle.

The last-named is, of course, tubular and carries at its ends arms for the head bearings. A further advantage of the final gear reduction is that not only the universal joints and shafts can be of moderate dimensions, but also the differential and driving gear. This represents a saving of weight, as well as space. Furthermore, the bevel gear need not give so low a reduction as is customary. This is helpful from the design viewpoint.

The Icirkstall Co. also produces a. corresponding rear axle. This of course, does not steer, but it embodies hubs, brakes, final-reduction gearing, differential, etc.. identical with those on the front axle, so that the majority of the parts is interchangeable, For trailers of medium and heavyweight type, Carrimore Six-Wheelers, Ltd., makes proprietary axle assemblies. A simple example is illustrated. Another is a bogie unit with two full-width axles and the wheels in tandem. A third employs short rocking axles and has the four wheels arranged in line. All are supplied complete with springs, brake gear, etc. This concern is also noteworthy for its unique retractor semi-trailer coupling gear which enables the front of the load-carrying platform to be carried forwards to within a few inches of the cab back.

Coupling gearbox and axle, in a big proportion of ail British commercial-vehicle chassis, is a jointed shaft of one or other of two famous makers. Neither can he said to represent any notable recent developments, but the fact that brains are not idle on the problem of universal joints is evidenced by the announcement lately of a joint developed by Silentbioc, Ltd., in which a pair of spiders is coupled by rubber bonded to each, and by a French invention incorporating, essentially, inner and outer spheres attached by bonded rubber, this material, in both cases, resisting the whole deflection and driving forces, permitting angularity and affording resilience.

Therein, of course, they resemble the Layrub, but a point stressed by the Laycoek Engineering Co., Ltd., its maker, is that, by employing rubber in the manner it does, variations in distance between sprung gearbox and unsprung axle are taken by the rubber without undue end thrust In the shaft produced by Hardy Spicer and Co., Ltd., these alterations in the length of the shaft are provided for by sliding splines. This concern, however, is.awake to the possibilities of rubber, and recently patented a scheme for its use in a closely associated connection, namely, to house the propeller-shaft centre bearing, thereby solving the problem of establishing and maintaining correct alignment of this unit.

Rubber is 'being employed in the construction of chassis to an increasing degree and, moving methodically, as was our original ambition, to yet another transmission component, we find an English inventor applying it to the mounting of clutch centres, with the object of eliminating judder or rough clutch engagement.

In hydraulic couplings many improvements and experimental modifications have been recently recorded, showing that interest is very much alive and progress continuing.

To the Borg and Beck Co., Ltd., however, one turns for the most widely employed proprietary orthodox mechanical device. Representative of this concern's products, for all sizes of commercial vehicle, are models of the single

dry-plate type, with graphite-lubricated release bearings and spring or rigid centres. .They are suitable for separate or unit-mounted gearboxes.

Before turning to brakes, which generally rank as next in importance after transmission units, among chassis components Or items of equipment, we should make reference to a recent patent taken out under the name of the Mechanization Experimental Establishment, dealing with a 'device for progressive four-wheel steering. This ties up with our earlier remarks about the trend towards fourwheel-driving vehicles, and this invention goes a step farther, because it applies to vehicles which steer as well as drive on all four wheels.

The patent relates to an extremely ingenious mechanism, by means of which the first part of the steering lock affects the front wheels, whilst the latter part of the movement of the steering wheel is answered by the rear wheels. From the viewpoint of the ordinary operator this is a development of more academic than practical interest, but it is by no means without significance. As an example of the converse, one may take the current products of Cam Gears, Ltd., as typifying what orthodox steering-gear manufacturers are doing. Basically, the object is to achieve precision, freedom of .action, light weight and economy, and in the well-known product of this company one finds these aims reflected. In the field of brakes, afi effort to simplify maintenance is manifested in a recent Bendix device, the essence of which is a remote control for shoe adjustment. Instead of groping about with a spanner or screwdriver to gain access to an adjuster in the hub, the driver or mechanic can operate with his hand a simple control, reasonably accessibly mounted, which actuates the adjuster through the medium of a flexible cable.

Almost without exception modern brakes are of ths internal-expanding type, but New Hudson, Ltd., the maker of the Girling brake, is interesting itself in a disc brake. We do not think that the design is sufficiently advanced, so far, for any forecast to be made as to its future prospect, but significance again attaches to this line of research. This concern's standard product is of the two-leading-shoe type, and the device is ingenious and effective.

Briefly, the scheme is to construct the trailing shoe with the facing unit on a carrier, to which it is not rigidly fixed. By this means, when the carrier is expanded in the ordinary way, the shoe itself advances with the brake drum until it comes up against a stop adjoining the expander. Then the self-energizing effect comes into operation. The expander simply brings the shoe in contact with the drum, and the shoe is so arranged that it behaves in a manner similar to the leading shoe. Two accompanying illustrations depict items of the range of Lockheed brake apparatus. One shows the transverse cylinder and bisector device, which .is well known as a first-class retardation mechanism, and the other shows a combination of the Dewandre vacuum servo and Lockheed master cylinder.

The Automotive Products Co., Ltd., also offers a telescopic device for application by makers using their own shoe assemblies and, of course, a system in which no auxiliary power is employed, brake application being solely by muscular action.

Some troubles have been experienced with compressedair brakes and other systems, through condensation of moisture, which freezes in exceptionally cold weather. As a protection against this, the Westinghouse Brake and Signal Co., Ltd., produces an anti-freezer. A sectional illustration shows this device. It comprises, briefly, a reservoir containing a wick, the top of which is exposed to the air stream. Alcohol vapour is given off and condenses with the moisture ; having a much lower freezing paint than water, the mixture prevents the formation of Trouble from freezing-up of the system has also been experienced with vacuum brakes, also through water being drawn in via the air intake, which floods the apparatus. To render it impossible for moisture to enter. Feeny and Johnson,. Ltd., recently introduced a valve, having a remote air intake, which can be mounted in a protected place. In the F. and J. system, of course, there is no other point of entry for water, the bellows being hermetically sealed.

Improvements of a detail nature have been effected to multi-stroke hand-brake levers (such as are commonly used on trailer outfits), notably the Carrimore and the Neate. In the latter case, the modification relates to the device for releasing the pawl, which prevents the return of the cable wheel.

Also produced by the Trailer Appliance Co., .Ltd., maker of the Neate brake, are items of equipment such as power and hand winches of the ordinary and .capstan types, an illustration of one of-which is included, a useful clamp for cable splicing for service in conjunction therewith and other purposes, etc.

Turning now to suspension systems, reference is merited by a new development emanating from the Firestone Tyre and Rubber Co., Ltd., which recently announced a patented pneumatic apparatus. It will be interesting to follow its fortunes. That there is scope for this principle is evidenced by the continued, indeed, widening, use of the Gniss " air spring," for example, by the military authorities.

James Woodhead and Sons, Ltd., is a big commercialvehicle spring maker, and two items from its extensive range warranting mention are the substitution for the shackle of a hardened roller, bearing on the turned-over end of the top leaf, and the use of serrated anchor plates for clamping springs to axles and thus preventing motion of the former on the latter, An accompanying picture shows another Woodhead. product—a laminated draw-bar attachment. A feature is the use of special wedge bolts holding the plates tight in the brackets, Spring repair as well as manufacture is a special line of

the Brockhouse company of which there are associated establishments, Richard Berry and Son, James Leach, J. Broelthouse and Co., Ltd., and Brockhouse Spring Service Co., in Birmingham, Leeds, Glasgow and London, respectively. "While you wait" is a 13rockhouse slogan and speedy repairing certainly appeals to commercial-motor operators.

Well known as a maker of helper springs, F. J. Evans, Ltd., offers an extremely comprehensive range for practically all popular commercial vehicles. Their application is chiefly where overloads are carried, or where lorries are habitually loaded .unevenly, such as those equipped for .transporting plate glass on a rack at the near side. While on the subject of suspension, we should include a few remarks about shock absorbers. Such devices are standardized in increasing numbers and their makers have not hem idle in respect of improving the efficiency of their functioning. As an example, there is the well-known Andre-Hartford of the friction type, which is robust, easily adjusted, and enduring, and requires practically no maintenance—not even lubrication. It incorporates friction discs of non-corrosive material, which last almost indefinitely, whilst the ingress of moisture or dirt is positively prevented. In addition to the application of shock absorbers for improving suspension, they can be used for damping the motion of many other parts, notably trailer brake gear.

Tyres dip not come within the scope of this review, but the fact that the use of large-section tyre equipment increases has led to the incorporation on a greater number of both passenger and goods chassis of power-driven inflating devices. A pump of this description has just been introduced by the Clayton Dewandre Co., Ltd. It is built in two models of the same capacity—one of which is illustrated. The other differs only in respect of the mounting of the driving pinion; there is a second bearing in the

casing at the end remote from the crank, instead of one. The construction is evident from the drawing. It will be seen that air enters the cylinder by ports in the walls. which are uncovered wh6n the piston is at the bottom of its stroke. Discharge is by a disc valve in the head. The pump is supplied with an air filter, which prevents the passage of water vapour, oil mist, or solid bodies into the tyres. A pressure gauge is also provided.