HINTS ON MAINTENANCE.

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle,. to Secure Reliability and to Avoid Trouble.

ONTRIBUTIONS are invited for this page from fleet managers, drivers, garage foremen and mechanics, works staff and draughtsmen, and will be paid for on a generous scale. Every system, make, and type of commercial motor vehicle will be dealt with, and the matter should be written with a view to the disclosure of workshop and garage 'practice in the maintenance of a vehicle—practices

which, whilst they may be quite normal, are peculiar to the particular vehicle and may not be generaily known to those responsible for its running. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, headed "Roadside and Garage." Communications should be addressed to "The Editor, The Commercial Motor, 7-15, Rosebery Avent‘e, London, E. C. 1."

101.—J. Type Thornycroft Spring Clips.

After a very long run a special examination should be made of tile nuts and clips utilized for the purpose of holding the springs to the rear axle. The nuts should be quite tight. This is most important, as when the nuts are allowed to slack off the axle tends to turn over slightly, which is very detrimental to the worm drive and to both universal joints. A trouble which was recently experienced with the latter was completely cured by attention to the spring clips.

102.—Draining Water on B35 Type Halley.

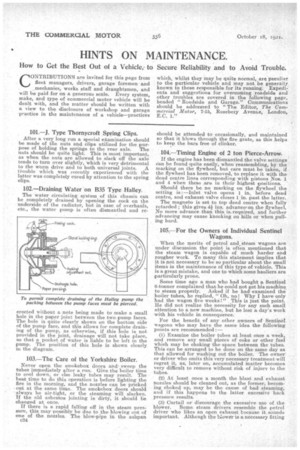

The water circulating system of this chassis can be completely drained by opening the cock on the underside of the radiator, but in case of overhauls, etc., the water pump is often dismantled and re

erected without a note being made to make a small hole in the paper joint between the two pump faces. The hole is quite clearly shown on the bottom side of the pump face, and this allows for complete draining of the pump, as otherwise, if this hole is not provided in the joint, drainage will not take place, so that a pocket of water is liable to be left in the pump. The position of this hole is shown clearly in the diagram.

103.—The Care of the Yorkshire Boiler.

Never open the smokebox doors and sweep the tubes immediately after a run. Give the boiler time to cool down, or else leaky tubes may result. The best time to do this operation is before lighting the fire in the morning, and the nozzles can be pricked out at the same 'time. The smokebox doors should • always he air-tight, or the steaming will slacken. If the old asbestos jointing is dirty, it should be changed at once.

If there is a rapid falling off in the steam pressure, this may possibly be due to the blowing out of one of the nozzles. The blow-pipe in the ashpari c34 should be attended to occasionally, and maintained so that it blows through the fire grate, as this helps to keep the bars free of clinker.

104.—Timing Engine of 2 ton Pierce-Arrow.

If the engine has been dismantled the valve settings Can be found quite easily, when reassembling, by the marking on the flywheel, but care must be taken' if the flywheel has been removed, to replace it with the dead centre lines corresponding with pistons Nos. 1 and 4 when these are in their highest positions.

Should there be no marking on the flywheel the setting is : —Inlet valve opens 1 in, before dead centre, and exhaust valve closes 1 in. past the latter.

The magneto is set to top dead centre when fully retarded ; this gives 4iins. advance.on the flywheel. No more advance than this is, required, and further advancing may cause knocking on hills or when pulling hard.

105.—For the Owners of Individual Sentinel Wagons.

When the merits of petrol and steam wagons are under discussion the point is often mentioned that the steam wagon is capable of Much harder and rougher work. To many this statement implies that it is not necessary to be so particular about the small items in the maintenance of this type of vehicle. This is a great mistake, and one to which some hauliers are particularly prone.

Some time ago a man who had bought a, Sentinel 6-tonner complained that he could not get his machine to steam properly. Asked if he had examined the boiler tubes, he replied, "Oh, no! Why I have, only had the wagon five weeks!" This is just the point. He did not realize the necessity for any such small attention to a new machine, but he lost a day's work with his vehicle in consequence.

For the benefit of any other .owners of Sentinel wagons who may have the same idea the following points are recommended :— (1) Examine the boiler tubes at least once a week, and remove any small pieces of coke or other fuel which may be choking the space between the tubes. This can be arranged to be done on the same day as that allowed for washing out the boiler. The owner or driver who omits this very necessary treatment will regret it, as, later on, accumulated matter becomes very difficult to remove without risk of injury to the tubes.

(2) At least once a month the blast and exhaust nozzles should be cleaned out, as the former, becoming choked up, may be the cause of bad steaming, and if this happens to the latter excessive back pressure results.

(3) Curtail or discourage the excessive use of the blower. Some steam drivers resemble the petrol driver. who likes an open exhaust because it sounds important. Although the blower is a necessary fitting

to a steam wagon the careful driver knows that the continual use of it is wasteful.

(4) Water should be drained from the crankcase each morning before the wagon is moved. From a Sentinel crankcase it should not be nebessary to drain off more than a cupful of water if the glands are in order. If more than this quantity passes into the crankcase and it becomes essential to remove the

piston rod packing, do not screw the gland too tight. 5) Ensure that the driver makes free and regular us4 of the grease gun provided by the makers. ) Do not worry too much about the terminal ra hanism of your wagon. Pay reasonable attentio to small items and adjustments and the engine wi I not want much worrying about, especially if there is ,La good driver at the wheel.