LEWIS TRANSPORT SERVICES

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

Crippling rates of fuel duty and road tax are forcing many UK hauliers out of business— but for Alan Lewis, the bigger the burden the better. Emma Davies reports...

Lewis Transport

RASED Ashbourne, Derbyshire.

FOUNDED 1988.

CONTACT James Eifel, transport manager.

FLEET Volvo FH12 tractor with a four-axle extendible Goldhofer semi low-loader; Volvo FH12 drawbar; 7.5-tonne and 3.5tonne lvecos; and a Vauxhall Astravan. Buys new. Most recent purchase: Volvo FH12 tractor and Goldhofer low-loader, September 1999.

SPECIALITY Heavy haulage.

TURNOVER .£1m-plus.

Alan Lewis has been carting big things about all his working life or, to be more accurate, he has been making sure that the moves go smoothly. On leaving school he went to work as a junior clerk for Pickfords, which was

then a major player in heavy haulage. Working his way through the ranks, he became transport manager, then commercial manager. At this stage many transport professionals feel the urge to go it alone; in 1988 Lewis was given a nudge in that direction—he was made redundant.

Rather than jumping in at the deep end with his own haulage operation he set up as a consultant, managing the movement of abnormal loads from door to door throughout Europe, Scandinavia, and North Africa. After some zo years in the business he knew he had his work cut out. Before they go anywhere, abnor mal loads have to be assessed on site. Drawings are made, generally using a computer aided design and draughting (CADD) system, then a route survey is made. At its most straightforward this involves measuring the height of bridges and checking the weight tolerance of roads to establish a safe route to a destination (which in Lewis's case could be as far away as Norway or Morocco).

Then there are permits and police escorts to sort out. This can be a headache, and waiting for an escort can keep a load marooned in a port for hours. Cranes may have to be hired and heavy-lift ships and inland barges could be needed for parts of the journey.

Minimal overheads

Lewis Transport Services (LTS) grew quickly for the first four years, helped by those minimal overheads—"no vehicles or drivers around our necks", he says—then revenue started to level off. "We could have continued purely as a consultancy," Lewis remarks, "but when we started all our vehicles were hired in from other companies and, from time to time, clients would ask who we were using. We knew that we had to buy our own."

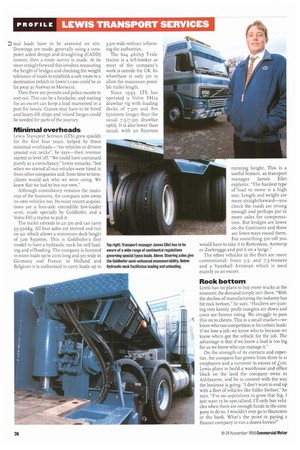

Although consultancy remains the mainstay of the business, the company now owns its own vehicles too. Its most recent acquisitions are a four-axle extendible low-loader semi, made specially by Goldhofer, and a Volvo FF112 tractor to pull it.

The trailer extends to 2o.5m and can carry 59,500kg. All four axles are steered and run on air, which allows a minimum deck height of just 890mm. This is Goldhofer's first model to have a hydraulic neck for self loading and offloading. The company is licensed to move loads up to 20M long and 3m wide in Germany and France; in Holland and Belgium it is authorised to carry loads up to

3.5m wide without informing the authorities.

The 6x4 46ohp T-ride tractor is a left-hooker as most of the company's work is outside the UK. Its wheelbase is only 3m to allow the maximum possible trailer length.

Since 1995, LTS has operated a Volvo F1-112 drawbar rig with loading decks of 7.5m and 8m (500mm longer than the usual 7.5/7.5m drawbar split). It is also lower than usual, with an 800mm

running height. This is a useful feature, as transport manager James Ellet explains: "The hardest type of load to move is a high one. Length and weight are more straightforward—you check the roads are strong enough and perhaps put in more axles for compensation. But bridges are lower on the Continent and there are fewer ways round them. For something 5m tall you would have to take it to Rotterdam, Antwerp or Zeebrugge and put it on a barge."

The other vehicles in the fleet are more conventional: lveco 3.5and 7.5-tonners and a Vauxhall Astravan which is used mainly as an escort.

Rock bottom

Lewis has no plans to buy more trucks at the moment; the demand simply isn't there. "With the decline of manufacturing the industry has hit rock bottom," he says. "Hauliers are quoting very keenly, profit margins are down and costs are forever rising. We struggle to pass this on to clients. This is a small market—we know who our competition is for certain loads. If we lose a job, we know who to because we know who's got the vehicle for the job. The advantage is that if we know a load is too big for us we know who can manage it."

On the strength of its contacts and expertise, the company has grown from three to II employees and a turnover in excess of fim. Lewis plans to build a warehouse and office block on the land the company owns in Ashbourne, and he is content with the way the business is going. "I don't want to end up with a fleet of vehicles like Eddie Stobart," he says. "I've no aspirations to grow that big. I just want to be specialised. I'll only buy vehides when there are enough funds in the company to do so. I wouldn't ever go to financiers or the bank. What's the point in paying a finance company to run a dozen lorries?"