STRONG COMPETITION FROM VOLVO IN 1967

Page 60

Page 61

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

By A. J. P. Wilding AM1MechE MIRTE T AM now able to reveal full details of plans to market Swedish 1 Volvo trucks in the UK. Preliminary information that a company called Ailsa Trucks Ltd. had been set up in Scotland for the purpose was given in COMMERCIAL MOTOR of September 30 And now, following a visit to the Volvo headquarters in Gothenburg, I can complete the picture. While in Sweden I was able to try the one model to be exported to Britain on the Volvc test circuit.

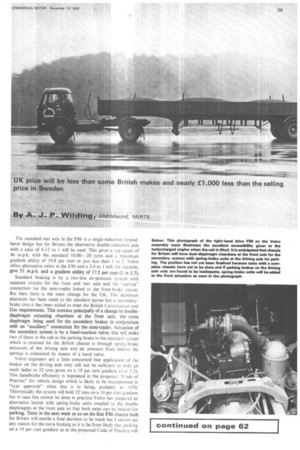

As reported in September, the model to be sold here will be the Volvo F86 tractive unit, a forward-control four-wheeler rated foi a maximum train weight of 32 tons. Basically, the design will be little changed for the UK. Wheelbase will be 3 m. (9 ft. 10 in. which is not new for the F86 although a wheelbase of 3.4 m (11 ft. 2 in.) is generally specified in Scandinavia and on the Continent. The chassis will naturally have right-hand drive whicl again is unusual for the model although it has been made in thi; form before. Main change is to the braking system which has ha: to be redesigned for Britain and there have also been small change to electrical components—lights and so on—to meet Britisl regulations.

F86 imports start next year. Three will be brought in at Oil beginning of January and 100 are expected to be available a montl later. The chassis will have a fairly rigid specification. The engin will be the Volvo TD 70 A turbocharged six-cylinder diesel with capacity of 6.7 litres. Maximum net output is 170 b.h.p. at 2,401 r.p.m. (195 b.h.p. gross) and maximum net torque is 398 lb. ft. a 1,400 r.p.m. (463 lb. ft. gross).

Transmission is through a Volvo R50 gearbox which gives eigh fully-synchronized forward ratios. This is a two-range gearbo with a four-speed front section and a two-speed rear. Ratios ar 10.18, 7.02, 5.03 and 3.78 to 1 with the low gear in the auxiliar section engaged and 2.69, 1.86, 1.23 and 1 to 1 in the high range There is only one reverse ratio-8.88 to 1—and the four-spec main section of the box is changed manually by a floor-mounte lever while the rear two-speed change is made electro-pneumaticall by a switch on the gear lever. The standard rear axle in the F86 is a single-reduction hypoidbevel design but for Britain the alternative double-reduction axle with a ratio of 6.12 to 1 will be used. This gives a top speed of

46 m.p.h. with the standard 10.00 20 tyres and a maximum gradient ability of 19.8 per cent or just less than I in 5. Volvo offers alternative ratios in the F86 and a 5.4 to 1 will. br example, give 51 m.p.h. and a gradient ability of 17.5 per cent (1 in 5.7).

Standard braking is by a two-line air-pressure system with separate circuits for the front and rear axle and the ''service" connection for the semi-trailer linked to the front-brake circuit. But here there is the main change for the UK. The minimum alteration has been made to the standard layout but a secondarybrake circuit has been added to meet the British Construction and Use requirements. This consists principally of a change to doublediaphragm actuating chambers at the front axle, the extra diaphragm being used for the secondary brakes in conjunction with an "auxiliary" connection for the semi-trailer. Actuation of the secondary system is by a hand-reaction valve; this will make two of these in the cab as the parking brake in the standard system which is retained for the British chassis is through spring-brake actuators of the driving axle and air pressure from behind the springs is exhausted by means of a hand valve.

Volvo engineers are a little concerned that application of the brakes on the driving axle only will not be sufficient to hold an outfit laden to 32 tons gross on a 19 per cent gradient I in 5.3). This handbrake efficiency is stipulated in the proposed "Code of Practice" for vehicle design which is likely to be incorporated in "type approval" when this is in being, probably in 1970. Theoretically the system will hold 32 tons on a 19 per cent gradient but in case this cannot be done in practice Volvo has prepared an alternative layout with spring-brake units coupled to the double diaphragms at the front axle so that both axles can be braked for parking. Tests in the next week or so on the first F86 chassis built for Britain will enable a final decision to be made but I cannot see any reason for the extra braking as it is far from likely that parking on a 19 per cent gradient as in the proposed Code. of Practice will

have to be demonstrated. It is more likely to be a theoretical evaluation so it is probable that the simpler system will be used by Volvo. Apart from the adding of a secondary circuit there have been only minor changes to the brake layout, including the addition of such things as low-pressure warning buzzers to comply with British regulations.

A light-laden valve is standard at the driving axle to reduce the braking effort at the rear when the outfit is partly laden or empty although Volvo does not recommend this equipment unless a similar unit is fitted at the semi-trailer axles. Brake sizes give frictional areas of 312 sq. in. at the front and 415 sq. in. at the rear axle and an exhaust brake is a standard fitting. Also standard is power steering with a ZF cam and roller box and an hydraulic ram connected to the drop arm.

I was unable to put the F86 through an extensive test in Sweden but I tried out a tractive unit coupled to a semi-trailer and grossing about 23 tons together with an empty rigid. The vehicles were very pleasant to handle and particularly praiseworthy were the very low level of engine noise in the cab and the excellent and effortless gear change. The use of two distinct ratio ranges with only one change in the auxiliary section when going up or down the gearbox was certainly an improvement on IMOspeed axle changing and the more usual splitter-type transmissions that 1 have met previously. Braking was very good and progressive although full pressure stops could not be made due to the track being very wet and causing all the tractive unit wheels to lock even on medium-pressure stops.

Power available from the engine was more than adequate for 23 tons but I would defer judgment on the situation with 32 tons gross as 170 b.h.p. is not now considered adequate in this country for this weight. Although theoretical gradient-ability is adequate, 170 b.h.p. gives less than the 6 b.h.p. per ton generally agreed as the minimum requirement.

Cab finish and fittings are to a high standard and good access is given to the engine when the cab is tilted; the effort needed foi tilting is slight and only one lever and a catch needs to be operatec before this is done.

The cab and the chassis give evety indication of being robust designed and on tours of the Volvo chassis and engine plants th( quality of the design and the workmanship put into producing th( chassis were quite obvious.

I have no doubt that the F86 will be competitive as a desigr with its British counterparts. And on the other three importan marketing factors—price, delivery and service—the chassis looks likely to be on the right side. The price being quoted is £3,50( basic, including heating, light-laden valve, power steering and s( on but with an extra £98 for the double-reduction rear axle. It i hard to see how this low total price of £3,598 can be asked fo the chassis because it has a list price in Sweden of £4,350 befor. taxes.

Delivery of the F86 should be very good and Ailsa truck Ltd. plans to ensure that adequate spares and service facilitie are available in Britain. Mr. J. McKilvie, managing director of th. company, knows what operators require as he ran the famil haulage business which was sold to the Transport Developmen Group in 1963. Negotiations with Volvo went on for about a yea before the appointment of Ailsa as concessionaires for the UK There is no financial connection between Volvo and Ailsa Trucks

Plans for Britain include the setting up of about eight depot covering the whole country and the first, in Glasgow, is alread in existence. Ailsa depots in London and Manchester are planne as the next stage and supervisory staff for these' as well as th Glasgow depot are already in Sweden undergoing special trainint Mr. McKelvie also spoke of plans to increase the range of model marketed in Britain and these include the possibility of importin long-wheelbase F86 chassis and fitting York third axles to sell a 22-ton gross six-wheelers. There is also the possibility that th larger F88 forward-control design from Volvo which has 250 b.h.p, net turbocharged diesel will be imported.