• Clues from PATENTS

Page 80

Page 81

Page 82

If you've noticed an error in this article please click here to report it so we can fix it.

• By A Special Correspondent

THERE is, perhaps, nothing analogous to a sheaf of patent specifications. Every emotion is . contained in them. A lone inventor is prey to vain imaginings, alternating— if he is lucky—with flashes of genuine inspiration. A sense of hopelessness or haplessness is a common trait of the inventive mind.

Dream's of stardom on stage or screen are as nothing compared with the dream of creating a workable mechanical symbol of the ego. Like every true romantic, the inventor is proof against ridicule. With the romantic's idealis m, his mind transcends the sordid economics of production.

How fortunate! Many outstanding inventions were a hundred years before their time. They merely could not be put into production by methods known at the time.

So the inventor is not a bad fellow after all; but to use his approach to an appraisal of recent patents with regard to future trends would be extremely confusing.

The inventor strives to create some thing without worrying overmuch whether it will benefit anyone when the job is finished. In contrast, the practical investigator bases his valua tions on the known requirements of B46 manufacturers, but, paradoxically, because he cannot have a universal knowledge of such things, it is necessary in some cases for him to judge the substance of need by the number of patents that promises to solve associated problems. This particularly applies if the patentees have importan names.

Take the case of the high-outpu turbocharged engine. It is knowt that an increase in cylinder pressun of at least 50 per cent. in the next fev years is envisaged. Injection difficul ties are expected.

Many patents in the past two year have been devoted to improved injec tion systems. Experimental engine: have given outstandingly high outputs The need for better pump-injectiot characteristics has been fairly urgen for some time, and the patents sbov that corresponding steps are beim taken to meet it.

Now consider the variety of specifi . cations dealing with hydrostatil transmissions, the basic principles o. which were, for the most part patented more than 50 years ago. Ai efficient hydrostatic . system cold( revolutionize vehicle design, but th4 need has persisted as a.vacuum for st many years without any seriou: attempt to fill it that it is no longe: recognized as such.

Significance of Names

Everything that can be said in it; favour has been said many time: before. The possibilities of the systen must, therefore, be assessed by th■ number of patents taken out and, a greater importance, the significance o the names behind them.

Specifications published since l95' show that high-level brains in th

3.M.C. and Ford organizations have ;iven a great deal of thought to tarious forms of hydrostatic transfission. .A small improvement in fficiency would give it an unassailable idvantage. (at the right price) over all )ther established forms of transnission. A well-known gearbox nanufacturer has stated that it is the titimate form of transmission. Who vill make the ultimate a reality? 3.M.C.? Ford?

Rover have also patented a hydrotatic system, in this case for frontvheel drive. Why not start by pplying it to a " secondary " drive of his type, which is used only occaionally? Efficiency would be a minor onsideration if the system were cheap nd light.

Reverting to oil engines, the basic hortcorning of compression ignition is hat air utilization is low—about per cent, in a typical unit. An acrease to around 80 per cent. would le a big help. The need is there and .o one can say that an improvement 3 impossible.

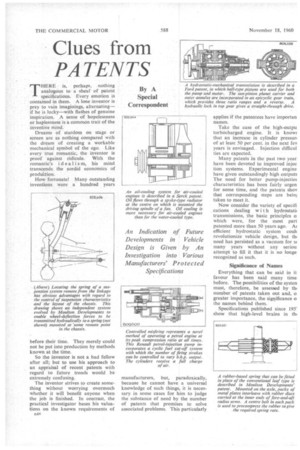

Advanced Types

A search through the patent file eveals that many advanced types of ombustion chamber and of injection ystem have lately been evolved, but o patent specifically mentions air tilization.

Reading between the lines, however, le specification of a porous combuson chamber of German origin (The 'ontinercial Motor, March 18) gives romise that a new principle will be pplied to this problem. Fuel is prayed on to the sintered lining of le chamber (located in the piston) nd is said to seep out during ombustion.

In the process it should mix with le air on the surface, and all the air -rould be burned. Maybe something etter than 80 per cent. air utilization will be achieved. The air clinging to the chamber surface and hiding in odd corners is the air that escapes burning.

Odd corners include the squish area, so it would seem appropriate to give this a porous lining, too. If it were possible to step up air consumption to 100 per cent., this would raise the output to turbocharged level without a turbocharger.

One hears that the oil companies are at their wits' end to know what to do with all the surplus petrol on their hands. Compression ratios are going up, but part-throttle fuel wastage is the main bogy of the petrol engine. It has been seriously suggested that a vehicle should be fitted with two engines, and that only one should be used for lighter loads. This is a clumsy way out of the difficulty.

Less clumsy is the proposal of the Renault company in a patent (April 17, 1959) to provide "controlled misfiring" of a six-cylindered engine with the aid of petrol injection. There would be no throttling of the air, and either the full quota of fuel would be injected into the air stream or the supply would be cut off altogether, cut-off being arranged in a planned sequence to reduce output.

For example, instead of 100 firing strokes in 200 revolutions, the number could be reduced to 12, each cylinder firing twice. Running would be rather rough at low speeds, but it should be possible to provide for normal firing below certain revolutions.

If the system gave the economy of the oil engine, there would be a queue of buyers. The General Motors Corporation also appear to recognize its possibilities, according to a patent published last year (August 21).

Petrol-injection systems are costly, but that is because they are made in small quantities. A review of associated production factors by a well-known American technician some five years ago indicates that quantity production

could reduce the cost to a few pounds.

If a reader was unaware that the use of disc brakes could create overheating problems, a glance through current patent specifications would give him the idea, Schemes for cooling disc brakes with water or other fluid show that makers are viewing the problem with great seriousness, without apparently being embarrassed by the manifold, complexities involved.

In a Dunlop patent (September 11. 1959) the features of a scheme for heavy commercial vehicles include a double-walled body jacket for circulation of the brake cooling liquid. The specification suggests that the space could he electrically heated.

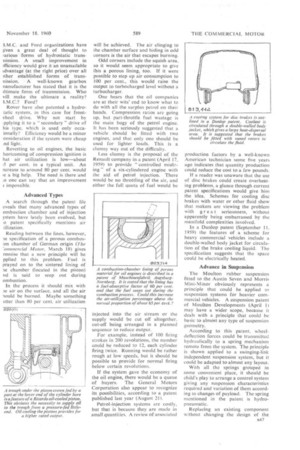

Advance in Suspension

The Moulton rubber suspension fitted to the Austin Seven and Morris Mini-Minor obviously represents a principle that could be applied to suspension systems for heavier com mercial vehicles. A suspension patent

of Moulton Developments (April 1) may have a wider scope, because it deals with a principle, that could be

basic to almost any type of suspension geometry.

According to this patent. wheel deflection forces could be transmitted hydraulically to a spring mechanism remote from the system. The principle is shown applied to a swinging-link independent suspension system, but it could be adapted to almost any layout.

With all the springs grouped in some convenient place, it should be child's play to arrange a control system giving any suspension characteristics required and variation of them according to changes of payload. The spring mentioned in the patent is hydropneumatic.

Replacing an existing component without changing the design of the chassis offers ease of adaptation that can popularize a new scheme at small cost to the vehicle maker. A relatively simple type of suspension also patented by Moulton Developments (December 25, 1959) may, therefore, have a greater significance.

In this case, the patent refers to a rubber suspension unit that has the general form of a conventional leaf spring and can be fitted in its place. Packs of rubber discs and steel plates are located At the inner ends of radius arms and are linked to the beam axle. A special feature of the sandwich pack is a central bolt with which the spring can be preloaded to change the suspension rate.

The idea of the spring wheel is as old as the car. It seemed to die a natural death, but has recently been revived, notably by a number of German companies. If an efficient, reliable and low-cost type of sprung wheel could be evolved it would have a strong appeal. It would greatly simplify chassis design.

Few patents refer to innovations in cooling systems, but a recent specification originating in Los Angeles (May 27) shows a modern version of an old idea in the form of steam cooling. This is complicated by the use of a cold header tank and a heat exchanger, as well as a radiator, but the scheme is a reminder that steam could be used to drive a low-boost turbocharger.

Perhaps the steam could be mixed with exhaust gas and thereby give more favourable temperature conditions. So long as the temperature of the intake air was not appreciably increased by steam cooling, it would tend to raise the combustion efficiency of oil engines.

Another cooling system is novel in detail (Serck Radiators, December 25, 1959) and may have wider implications, in that it is a combined oil radiator and fan unit for air-cooled engines. Oil cooling can become a major problem in an air-cooled engine (without oil-cooled pistons) and Serck offer a fairly simple way of controlling the temperature.

Air cooling is mentioned in other patents, but they do not provide enough evidence to justify the conclusion that it is being considered. So many attempts have been made to produce a controlled-slip differential for commercial applications at reasonable cost that patents covering new types can easily be overlooked. But the need is there, and it is urgent.

Just how urgent it is in the case of, say, a tipper on rough site work, is difficult to guess, but it could be more of a boon than is generally considered possible. Less bogging down and transmission troubles on site and better • vehicle control on icy roads represent big potential gains.

One patent (V. Gleasman, January 23, 1959) mentions that the number of worm wheels employed in the differential to control slip can be increased for applications to heavier vehicles, and a Rover patent (February 1, 1957) particularly mentions the use of a multiple plunger type as the third differential of a four-wheel-drive system. In this case, the housing is filled with a thick oil, or other viscous liquid, which, by inhibiting the movement of the plungers, practically locks the differential when a small difference in revolutions is exceeded.