OUTSTANDING CH.A.

Page 58

Page 59

Page 60

Page 61

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

;IS TECHNICALITIES

at the Scc

ish Show

A Critique of Modern Design as Exemplified by the Exhibits at Glasgow. The Numbers in Brackets Indicate the Stands on which Exhibits may be Found Transmission Developments the Predominant Feature. Braking and Lubrication Simplified. Better Engine Mountings. Maintenance Problems Solved

UNDOUBTEDLY transmission developments provide the subject of greatest interest at this year's Scottish Shaw. All Daimler vehicles shown (90) incorporate the Daimler fluid flywheel and epicyclic gearbox. A variation, as compared with the Daimler layout, in the use of the Wilson epicyclic gearbox is shown by Crossley Motors, Ltd. (86), on a six-wheeled oil-engined double-decker chassis, in which this gearbox is positively coupled to the engine, without a clutch, the friction bands of the gearbox being relied upon to transmit the torque, even for starting from rest.

This is the principle adopted in certain private motorcars, and it will be interesting to see from subsequent experience whether it will prove successful with vehicles weighing over 10 tons when fully laden. The effort required to operate the gear-change pedal (taking the place of the normal clutch pedal) is, in this instance, provided by means of a vacuum cylinder.

The Dennis easy-gear-change system is shown as a separate exhibit (73). In this mechanism, fully described in The Commercial Motor on October 28, the gearbox is isolated from both engine and road wheels at the time when gear changes are made. A vacuum cylinder is provided which withdraws the clutch, at the same time disengaging a dog coupling behind the gearbox.

In order to get quick action, a solenoid is used to bring the vacuum device into operation. The driver depresses the solenoid button and the clutch pedal is pushed down for him. If the mechanism should fail in any way, he is left with the ordinary operation.

The adoption of the Salerni fluid clutch before the gearbox, in conjunction with the Salerni coupling behind the gearbox, is an interesting development of T.S. Motors, Ltd. (80). In this case, as the pedal is depressed, its first movement closes a ring valve in the fluid clutch, so that torque ceases to be transmitted to the gearbox. Further travel of the pedal separates the dogs of the Salerni coupling, and still further movement applies a brake to the clutch shaft. With the gears practically at rest rapid changes are made.

As the pedal is released, the reverse action takes' place, except that, unless the engine be accelerated so that the speeds of the dogs synchronize, the Salerni coupling does not engage; but, due to the provision of an interrupter ring, the dogs do not meanwhile override each other, and subsequent engagement is silent. Until this engagement occurs freewheeling takes place. This means that deliberate freewheeling is available at any time, the driver simply depressing the pedal and releasing it again without accelerating the engine. Automatic replenishment of oil to the fluid clutch is a useful provision, and the fact that the company's welltried Express gearbox can be used is advantageous.

It seems inevitable that definite aids to gear changing, such as these, obtained without undue complication, must receive greater attention in the future.

On certain Thornycroft models the Millam free wheel is offered as a standard extra, and this deVice, as well as its separate components, is available for close inspection (88). The free wheel is fitted behind The gearbox, and, in its latest form, has been made more compact for accommodation beneath the floorboards. The model offered by the maker, Sir W. G. Armstrong Whitworth and Co. (Engineers), Ltd., Newcastle, for all commercial vehicles, weighs 11 cwt.

Freewheeling or fixed drive is available by movement of a lever, without first bringing the vehicle to rest, and there is a sprag which conies into operation at speeds below 2 m.p.h. This sprag does not act, of course, when the drive is fixed. A point about the Millam gear is that there is pump lubrication to the splines, free-wheel pads, etc. Apart from giving improved fuel economy, an important thing with the present high price of petrol, the free wheel eliminates reversal stresses in the transmission.

The Maybach pre-selective easy-change auxiliary gearbox, with constant-mesh helical gems, deserves favourable mention, as it gives the driver security and comfort on a hilly journey, as well as keeping down engine speed and fuel consumption, particularly wheA travelling on the level. As fitted to the Armstrong-Saurer vehicles it gives eight forward speeds. These vehicles, incidentally, would hardly be improved by a free-wheel device, because their highly efficient compressed-aii brakes render coasting a safe procedure.

A more orthodox eight-speed gearbox is seen on the Foden Gardner-engined chassis (92), and the Scammell five-speed gearbox with but two shafts is another type produced for accommodation of the oil engine (109).

Constant-mesh third gears, engaged by positive clutches, are seen on several chassis, including Albion (72), Commer (74), etc.

This year's Show affords many illustrations of the use of rubber for universal joints. The only exposed universal joint on the Armstrong-Saurer Diligent chassis (79), for example, has Silentbloe bushes, whilst another ease is that of certain Commer chassis (74).

With regard to chassis design, efforts made to obtain wide frames are, we th nk, always justified by resultant lateral stability. As the Crossley six-wheeled double-decker chassis is shown without bodywork (86), the width of the frarae between the four single-tyred rear wheels (4 ft. 7 ins.' is noticeable ; the springs actually come beneath the frame members. Another chassis on which the springs are mounted in line vertically with the frame longitudinals is the Foden four-wheeler (92), the overall frame width in this case being 3 ft. 2 ins.

Box-type frame strengthening is illustrated by the Halley Clansman chassis (84), the engine sub-frame acting as a downward arch, level with the clutch, whilst in the same place an upward-arched cross-member completes the extremely stiff box effect.

The employment of welding processes becomes more common, a remarkable .case being afforded by the three-piece final-drive housing of the Armstrong-Sewer Dominant sixwheeler (79), the whole of which is made from hot pressings and other sections welded together. The use of light metals is common in connection with gearboxes, crankcases, etc., the Daimler chassis (90), in particular, incorporating many light-metal parts, including the fluid flywheel, the worm casing of the axle, etc.

Unorthodox chassis layout, is, at this Exhibition, illustrated in the T.S. Motors 2-tonner (80), intended for refuse collection, local deliveries and the transport of container or lift-van bodies. In this case, the frame is down-swept at the front, affording a very low full-width driver's platform, the engine being mounted between and beloiw the frame mom B34 hers amidships. it is a vity that the A.E.C. side-engine motorbus could not be exhibited, although, of course, the company regards this at present as an experimental machine.

The avoidance of unnecessary chassis weight is emphasized-in the case of the Commer maximum-load four-wheeler, shown by Wylie anl Lockheed, Ltd. (83). According to the maker, this chassis can legally take a pay-load of seven tons. Another case is the Albion heavy-duty four-wheeler (72), which can carry over six tons, together with a fullweight body.

The bold use of really large springs is evidenced by the

Armstrong-Saurer six-wheeler (79), the driving bogie of which supports the frame through a pair of semi-elliptic springs, 9 ft. 5 ins, long and 41 ins., wide, each comprising five leaves 1-pg in. thick.

The chassis, as well as many others, employs rubber bushes of the Silentbloc type for spring eyes and shackles, and it should be understood that these not only eliminate need for lubrication, but also z‘bsorb small shocks, protecting the springs and chassis.

Rubber bushes are being incraasingIy used for universal joints, notable examples being the Commer 3-tonner (74) and the Armstrong-Saurer 4-5-tonner (79). In the latter case the only exposed joint in the propeller shaft has rubber bushes, the joints at the shaft extremities being housed respectively within the gearbox and the axle case, so that they are automatically lubricated.

Where there are many chassis points requiring lubrication, the grouped-nipple system seems now to afford the solution, good examples of the Tecalemit equipment being seen on the Leyland Bull (110) and the Daimler chassis. (DO).

Low-pressure tyres for double-deckers are a promising development, illustrated by at least two new models in this class. The Albion Venturer -(72) has 10.50-in. by 20-in. front tyres and 9.00-in. by 20-in. rear tyres, whilst the Gilford Zeus (P9) has 9.75-in. by 22-in. tyres on all wheels. In both these cases twin tyres are 'fitted to the rear wheels, but we cannot help thinking that, before long, single rear tyres of larger section will become popular. Apart from giving better insulation, single tyres permit a wider ,frame, which means increased stabilitz.and permits the use of more resilient springs.

Engine developments are principally of a detail nature. Oil engines are offered as standard or optional equipment in practically every make of chassis, but no exhibitor as yet displays a petrol engine converted for burning creosote. Some success is being obtained in this direction, but mainly by operators.

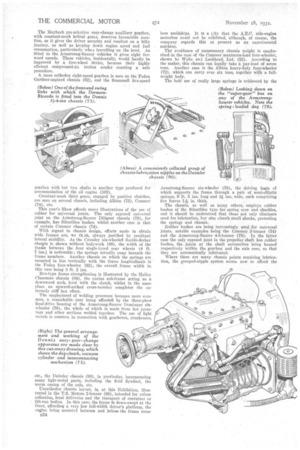

As regards oil engines, one of the most interesting developments is seen in the new fuel-injection pump on the Beardmore engine (100). In this the plunger is drilled so that the helix controlling the commencement and finish of Injection mates with apertures some distance from thc top of the plunger. Side thrust on the plunger is thus practically eliminated. A full account of this pump appears in a separate article in this issue on page 465.

The latest C.A.V.-Bosch governor, already described in this paper, apart from being commendably simple and efficient in design, is particularly compact, being entirely enclosed in a small light-alloy housing forming an extension of the fuel-pump body. It is seen on ArmstrongSaurer, Leyland and Thornyeroft vehicles (79, 110 and 88).

The Leyland engine., it may be noted, has a cavity in the piston crown into which injection takes place, it being claimed that the spray is thus kept from the cylinder walls (110).

The Armstrong-Saurer concern is experimenting with new combustion systems, the latest at present available in this country being that incorporated in the Diligent vehicle, recently road-tested by us, and in all models displayed at Kelvin Hall (79).

As to petrol engines, examples of the high-camshaft type, giving efficiency with easy maintenance are seen in the new Albion Venturer (72) and the Morris-Commercial Courier (75). Oil coolers are fitted on several engines, including the Halley Clansman (84) and the Thornycroft (88), whilst accessible oil filters are now common. The Crossley oil engine (86) has a neatly mounted Tecalemit oil cleaner.

Two features of the Reo Gold Crown petrol engine (82) merit ref erence„although they are not new, The first is that nickel-chrome iron is employed for the cylinder-block casting, giving long life between periods when reboring becomes necessary. The second is that baffle plates are incorporated in the water jackets to cause the water to flow in such a way that an equal temperature is preserved between the individual cylinders. The practice was adopted after prolonged tests, demonstrating the increased efficiency obtained. Engine mountings designed to insulate vibration and torque reaction from the chassis frame are seen on probably the majority of the new models, good examples being the swing-link arrangement on the Dennis 3i-tonner and Lancet passenger chassis (73), the Commer light vans and the larger Commer models (74), also the Leyland Cob (85).

An ingenious face gland of graphite is used in the water pump on AEC. engines (91), in which, by the way, steel shells are used for the white-metal bearings. Another A.E.C. idea is to permit the self-starter current circuit to be completed only when the ignition is retarded. The accessibility of the magneto is emphasized in the high transverse mountings on Halley Clansman (84)! and Gilford Zeus (99) chassis.

An advanced type of biake equipment is seen on Arm, strong-Saurer vehicles (79), all of which incorporate the Knorr compressed-air brake, with application cylinders (fixed to the axles) of comparatively small bore and large stroke, enabling brake-shoe wear to be automatically provided for by a negligible increase in the amount of air used. The pressure available,adjustable while driving, is 100 lb. per sq. in. or more, giving great retardation power. The point about adjusting the air-reservoir pressure while travelling is that it enables skidding on slippery roads ..ro be avoided.

A combination of vacuum braking power and hydraulic transmission to the shoes is seen on the Dennis Lancet and 31-4-tonner (73) and, if desired, can be fitted to the T.S.M. Express chassis (80), which, in standard form, has only the hydraulic transmission. The mounting of Dewandre cylinders on the front-wheel brake assemblies is now common, typical examples being the Albion Venturer (72) and Daimler (90). Time lag in the operation of vacuum brakes is largely overcome by htting pipes of suitable diameter.

Ingenuity in brake-shoe design is displayed by the separate exhibit showing the brake assembly of the Dennis models mentioned above (73). Four quarter-circular shoes of width work in a 17-in, drum, which may be taken

off (by removing five countersunk screws) without disturbing the wheel bearing. Rigidity of the drum mounting is obtained by registering it on the hub, as well as on the 10 wheel studs. For refacing the shoes the shoe pivot pins can be driven through, after releasing set-screws ; and, so that no ribs may form in the pins where the edges of the shoes come, the pins arc recessed at the joints of the shoe binges.

On the Morris-Contmercial Courier (75) outside brake

shoe springs are employed, so as to permit easy removal of the shoes without detaching the hubs, whilst on the Leader 8-tonner of the same make .(93) brake adjustment is ob

B313 tamed in a clever way by using shoe-end plates, threaded on to the axial extensions of short worm wheels, these being engaged with transverse warms, which may be turned by Walls of a key inserted through the hack plate.

Flexibly enclosed cables for the final stage of brake application, i.e., from the chassis frame to the torque-reaction plate, as evidenced on the Commer 3-tonner (74) have established themselves as a satisfactory means for overcoming brake interference due to spring flexing. The systerd is particularly advantageous with rigid six-wheelers. Couplings of this kind are most useful also for the brake connections of detachable semi-trailers forming part of articulated vehicles. The Neate coupling incorporates the flexibly enclosed cable.

Hand-operated brakes which afford good leverage because the driver is able to make two or more pulls or pushes on the hand lever, are to be commended, provided that great effort is not required to effect release. A good example is seen in the case of the Leyland Bull (110), the brake lever of which acts on a double-ratchet wheel, this being turned through the medium of a fabric Band, tightened about the drum as the lever is thrust forward. It will be seen that with a band easy release is obtained without the driver experiencing any severe shock.

A good example of non-compensated linkage with a vacuum brake system is seen on the same chassis, the main cross-shaft being turned by a Dewandre vacuum cylinder at each end, so that the torque on the shaft is equalized. On the Gilford double-decker chassis (99) a very short first cross-shaft is employed and it is carried in ball bearings, as is the full-width cross-shaft behind it, the latter having three such bearings. Gifford vehicles have always been noted for easy brake action.

Steering gear to-day is usually a proprietary unit of welltried design and, even with most of the heaviest vehicles, lightness of action is obtained, as well as insulation from the shocks caused by road-surface irregularities. An interesting case of a well-arranged worm-and-nut gear is that of the Dennis, fitted on the Arrow, Lance and 3i-4-ton models (72). A long nut is employed, the length being no less than 6eins., and the thread is actually lined with whitemetal. Oil ways lead to this nut and, as the worm forces the nut downward, so oil is automatically forced into the bearing surface. The mild-steel drop arm employed in Armstrong-Saurer steering gears protects the other parts of the gear from damage in the event of an accident, and is capable of being reset (79).

Little need be said on this occasion concerning driving axles and final-drive units, except that the common practice now is to make the crown wheel and differential, together with the worm or bevel pinion, easily withdrawable. Fully floating axles are common, even on the smaller models, such as the Bedford 2-tonner (78), in the ease of which, incidentally, the axle assembly, cut away to reveal the manner in which the half-shafts and final-drive unit may be withdrawn from the banjo-type casing, is displayed as a separate exhibit.