For DRIVERS, MECHANICS & FOREMEN.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

P.RIZE 013' TEN SHILLIAG8 is awarded each week, to the sender of the best letter which we publish on this page ; all others are paid for at the rate of a penny a tine, with an allowance for photographs, All notes are edited oejore being published. Mention your employer's name, in confidence, as evidence of good faith. Address, D., M. and F., "The Commercial Illotor," 7-15, Rosebery Avenue, London, E,C, 1.

Lamps Alight.

On Saturday, November 22nd, light your lamps at a:32 in London, 4.24 in Edinburgh, 4.22 in Newcastle, d.36 in Liverpool,. 4.35 in Birmingham, 4.42 in Bristol, and 5.19 in Dublin.

An Unusual Engine Trouble.

The sender of the following communication has been awarded the 108. prize this week.

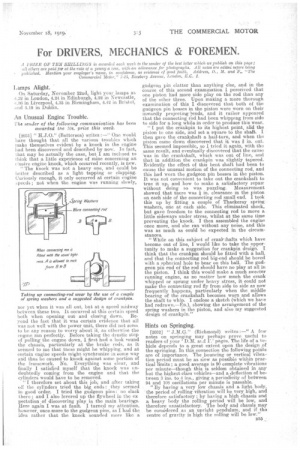

[2031] " H.J.0." (Battersea) writes;—" One would have thought that all the various treuble which make themselves evident by a knock in the engine had been discovered and described by now. In fact, that may be actually the case, but I am inclined to think that a little experience of mine concerning an elusive engine knock, which occurred recently, is new. "The knock was not a heavy one, and could be better described as a light tapping or clapping. Curiously enough, it only occurred at certain engine speeds; not when the engine was running slowly, nor yet when it was all out, but at a speed midway between these two. It occurred at this certain speed both when opening out and closing down. Beyond the fact that it was certain evidence that all was not well with the power unit, there did not seem to be any reason to worry about it. as otherwise the engine ran perfectly. Before taking the drastic step of pulling the engine down, I first had a look round the chassis, particularly at the brake rods, a-s it seemed to use that these might be whipping, and at certain engine speeds might synchronize in come way and thus be caused to knock against some portion of the framework. No. Everything was clear, and finally I satisfied myself that the knock was undoubtedly earning from the engine and that the cylinders would have to be removed.

"I therefore set about this job, and after taking off the cylinders tried the big ends: they seemed in good order. I tried the gudgeon pins: no slack there • and I also levered up the flywheel in the ex pectation of discovering play in the main bearings. Here again I was at fault. I turned my attention, however, once-more to the gudgeon-pins, as I had the idea miller that the knock sounded more like a

gudgeon pin clatter than anything else, and in the course of this second examination I perceived that one piston had more side play on the rod than any of the other three. Upon making a more thorough examination of this I discovered that both of the gudgeon pin bosses in the piston were worn on their inwardly projecting-ltends, and it rather appeared that the connecting rod had been whipping from side to side for a long while in order to produce this wear.

"I put the crankpin to its highest point, slid the piston to one side, and set a square to the shaft. I then gave the crankshaft a hail-turn, and when the piston came down discovered that it was in. -out. This seemed impossible, so I tried it again, with the same result, and eventually discovered that the cause 'was in the crankshaft, which was out of line, and that in addition the crankpin was slightly tapered. Evidently the effect of this bent shaft had been to cause the unusual motion of the connecting rod, and this had worn the gudgeon pin bosses in the piston. It was not convenient to take out the crankshaft to true it up, and how to make a satisfactory repair without doing so was puzzling. Measurement showed that there was t in. clearance in the piston

• on each side of the connecting rod small end. I took this up by fitting a couple of Thackeray spring washers, one at each side. This eliminated shock, but gave freedom to the connecting rod to move a little sideways under stress, whilst at the same time preventing the knock. I then assembled the engine once more, and she ran without any noise, and this was as much as could be expected in the circumstances.

"While on this subject of crankshafts which have become out of line, I would like to take the opportunity to make a suggestion for crankpin design. I think that the crankpin should be fitted with a ball. and that the connecting rod big-end should be bored with a spherical hole to bear on this ball. The gudgeon pin end of the rod should have no play at all in the piston. I think this would make a much sweeter running engine, as no matter how much the crank whipped or sprung under heavy stress, it could not make the connecting rod fly from side to side as now frequently happens, particularly when the middle bearing of the crankshaft becomes worn and allows the shaft to whip. I enclose a sketch (which we have had redrawn.—En.), showing the arrangement of the spring washers in the piston, and also my suggested design of crankpin."

Hints on Springing.

[2032] " J.M.G." (Richmond) writes :—" A few notes on springing may perhaps prove useful to readers of your D.M. and. P.' pages. The life of a Vehicle depends to a great extent upon the design of the springing. In this connection the following points are of importance. The bouncing or vertical vibration period must be as slow as possible within practical limits ; a good average is 90 complete vibrations per minute—though this is seldom obtained in any but the highest-class vehicles—and a deflection of between 3 ins. to 4 ins., giving a periodicity of between 94 and 108 oscillations per minute is passable. "By having a very low chassis and a light body.

• the period of rolling vibration will be very high, and therefore satisfactory ; by having a high chassis and a heavy body the rolling period will be low, and therefore unsatisfactory. The body and chassis may be considered as an upright pendulum, and if the centre of gravity is high the rolling will be low."