THE COMMER CAR PROGRAMME FOR 1920.

Page 23

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

The First of the New Models to be Delivered will be the Worm-driven 3P Type

Char-a-bancs.

AMONGST THE MANY British commercialmotor vehicles the name of Commer Car has always been well to the fore. Commercial Cars, Ltd., of Luton, did a considerable amount of pioneer work and from their beginning have concentrated entirely on vehicles designed lot commercial work. The unique experience Which the company have thus acquired by specializing in the problems, of heavy haulage, is a valuable asset which gives a good hart-off fir any new vehicles which may be produced by them. • ' •

During the war practically the whole outputof Commercial Cars was taken by the War Office, and many testirbonials were received as to the fine services which were rendered. by these vehicles -on the

-various fronts. Considering the .popularity which has been attained by Commer Cars, it is not surprising to learn that the present demand far exceeds the supply, in spite of an increased production.

An important feature is the close attention that the company has always devoted to the Overseas trade. In the designing of the Commer chassis particalar care has been paid to the requirements of the Colonial and foreign markets, with the result that Commer Cars are to be found in every country oT the globe where road conditions make motor transport at all possible.

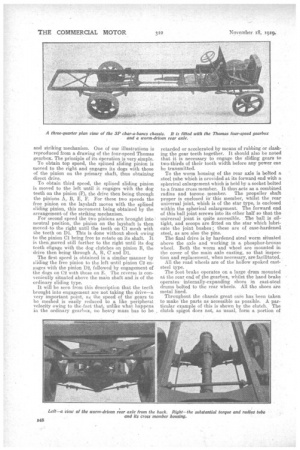

Towards the end of February delivery will commence of the new passenger 3P type, which has been designed to carry a 30-seated charsh-ba,ncs body. An experimental 3P type has been running on test for the past four years as a stares lorry ; thus it is under the direct observation of the designers, and it has been examined periodically in order to detect signs of wear, or any faults which may have developed. It has now run a distance of over 30,000 miles at a total cost for repairs of under £10. The work inEludes many long runs to the Black Country for stores, such as iron and steel. A description of the 3P. chassis may prove of interest to our reader a as it departs in many ways from Comrner. Car orthodox design. The frame is of pressed channel steel with stout cross members.

The engine has four cylinders, 115 mm. bore by 140 mm. stroke, cast in pairs: Lubrication is by pump, the big-ends dipping into oil troughs which are kept filled to a eimstant level. The operation of the pump is indicated by a telltale on the dashboard.

The principle of including the engine bearing cross members ,,as part of, the.. engine is adhered to. By this method the rear member actually carries the weight of the flywheel and thus relieves the aluminium crankcase from any risk of distortion caused by its weight. The front of the engine is held in a trunnion bearing on the front cross member, thereby obtaining a true three-point suspension through the trunnion bearing passes the starting handle with its bush.

The radiator is of the usual built-up, cast aluminium type provided with straight gilled tubes.

The clutch is of pressed steel construction, lined with leather, and is of large diameter, and the drive from the clutch to the gearbox is through a shaft fitted with a flexible steel disc universal joint.

The gearbox is, perhaps, the most interesting part of the chassis. It is a development of the Linley, which was used on previous models. It retains the principle of engaging the gears by means of dog clutches and at the same time keeps the minimum number of wheels in mesh for the different speeds, of which it has four forward and one reverse. It is very compact, only one splined shaft and sleeve being employed, and even on this shaft the splined portion is quite short.

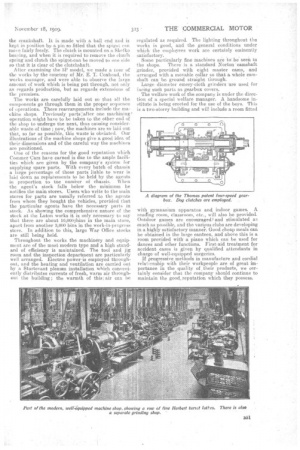

The length between the ball bearings of a fourspeed box to transmit 50 h.p. is only 121 ins., which is considerably shorter -than the majority of the ordinary sliding gear type gearboxes. The gearbox was designed and patented by MrThomas, the chief engineer at. the Comrner Car factory, and his patent also includes the simple locking and striking mechanism. One of our illustrations is reproduced from a drawing of the four-speed Thomas gearbox. The principle of its operation is very simple. To obtain top speed, the splined sliding pinion is moved to the right and engages its dogs with those of the pinion on the primary shaft, thus obtaining direct drive.

To obtain third speed, the splined sliding pinion is moved to the left until it engages with the dog teeth on the pinion (F), the drive then being through the pinions A, B, E, F. For these two speeds the free pinion on the layshaft moves with the splined sliding Pinion, this movement. being obtained by the arrangementof the striking mechanism.

For second speed the two pinions are brought into neutral position, the pinion on the layshaft is then moved. to the right until the teeth on 01 mesh with the teeth on Di. This is done without shock owing to the pinion 01 being free to rotate on its shaft. It is then,moved still further to the right until its dog teeth ofigage with the dog clutches on pinion B, the drive then being through A, B, C and Dl.

The first speed is obtained in a similar manner by sliding the free pinion to the left until pinion 02 engages with the pinion D2, followed by engagement of the dogs on 02 with those on E. The reverse is conveniently situated above the main shaft and is of the ordinary sliding type.

It will be seen from this description that the teeth brought into engagement are not taking the drive—a very important point, as. the speed of the gears to be meshed is easily reduced to a like peripheral velocity owing to the-fact that, unlike what happens in the ordinary gearbox, no heavy mass has to be. retarded or accelerated by means of rubbing or clashing the gear teeth together. It should also be noted that it is necessary to engage the sliding gears to two-thirds of their tooth width before any power can be transmitted.

To the worm housing of the rear axle is bolted a steel tube Which is provided at its forward end with a spherical enlargement which is held by a socket bolted to a frame cross member. It thus acts as a combined radius and throne, member. The propeller shaft proper is enclosed inthis member, whilst the rear universal joint, which is of the star type, is enclosed within the spherical enlargement. The forward end of this ball joint screws into its other half so that the universal joint is quite accessible. The ball is oiltight, and scoops are fitted on the star which lubricate the joint bushes ; these are of case-hardened steel, as are also the pins.

The final drive is by hardened steel worm situated above the axle and working in a phosphor-bronze wheel. Both the worm and wheel are mounte,d in the cover of the main axle casting, so that inspection and replacement, when necessary, are facilitated.

All the road wheels are of the hollow spoked eaststeel type.

The foot brake operates on a large drum mounted at the rear end of the gearbox, whilst the hand brake operates internally-expanding shoes in cast-steel drums bolted to the rear wheels. All the shoes are metal lined.

Throughout the chassis great care has been taken to make the parts as accessible as possible. A particular example of this is shown by the clutch. The clutch spigot does not, as usual, form a portion of the crankshaft. It is made with a hall end and is kept in position bya pin so fitted that the spigot can move fairly freely. The clutch is mounted on. a Skellto bearing, and when it is required to remove the clutch spring and clutch the spigot...can be moved to one aide so that it is clear of the clutchs,haft.

After exarhining.the 3P model, we made a tour of the works by the courtesy of Mr. E. T. Coxhead, the works manager, and were able to observe the large amount of work which is being put through, not only as regards PrOdu•ction, but as regards extensions of the premises.

The works are carefully laid out so that all the components go through them in the proper sequence of operations. These rearrangements include the machine shops. Previously partsafter one machining operation might have to be taken to the other end of the shop to undergo the next, thus causing considerable waste of time ; now, the machines are so laid out that, so far as possible, this waste is obviated.. Our illustrations of the machine shops give a good idea of their dimensions and of the careful way the machines are positioned. One of the reasons for the good reputation which Comnier -Cars have earned is due to the ample facilities which are given by the company-s system for supplying spare parts. With every batch of chassis a large percentage of those parts liable to wear is laid down as replacements tro be held by the agents in proportion to the number of chassis. When the agent's stock falls below the minimum he notifies the main stores. Users who wiite to the main stores for parts are usually referred to the agents from whom they bought the vehicles, provided that the particular agents have the necessary parts in stock. As showing the comprehensive nature of the stock at the Luton works it is only necessary to say that there •are about 10,000Nns in the main store, apart from another 3,000 bins in the work-in-progress store. In addition to this, large War Office stocks are still being held.

Throughout the, works the machinery and equipment are of the most modern type and a high standard of efficiency is maintained. The tool and jig room and the inspection department are particularly well arranged. Electric power 'is employed throughout, and Lae heating and ventilation are carried out by a Sturtevant plenum installation which conveniently distributes currents of fresh, warm air throughout the building ; the warmth of this air can he

regulated as required. The lighting throughout the works is good, and the general conditions under which the employees work are certainly eminently satisfactory.

Some particularly fine machines are to. be seen in the shops. There is a standard Norton camshaft grinder, provided with eight master cams, and arranged with a movable collar so that a whole cam

shaft can be ground straight through: • ' Large diameter emery-cloth grinder a 'are used for facing such parts as gearbox covers.

The welfare work of the company is under the direction of a special welfare manager. A handsome institute is being erected for the use of the boys. This is a two-storey building and will include a room fitted with gymnasium apparatus and indoor games. A reading room, classroom, etc., will also be provided. Outdoor games aro encouraged t and stimulated as much as possible, and the various clubs are developing in a highly satisfactory manner. Good cheap meals can be obtained in the large canteen, and above this is a room provided with a piano which can be used for dances and other functions. First-aid treatment for accident cases is given by qualified attendants in charge ofwell-equipped surgeries.

If progressive methods in manufacture and cordial relationship with their workpeople are of great importance in the quality of _their products, we certainly consider that the company should continue to maintain the good, reputation which they possess.