Petrol-feed Problems.

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

With Special Reference to the "Autovac" Petrol Feed, a System which Utilizes the Vacuum in the Induction Pipe to Draw Fuel from a Tank Anywhere in the Chassis.

The problem of suitable transference of petrol from supply tank to carburetter is not so simple as at first seems likely. Even when gravity feed, admittedly the easiest method, is employed it is not easy in every case to fix the tank so that for any likely positions of the chassis, whether ascending or descending a steep incline, there will be a minimum head of 3 ins. from the bottom of the supply tank to the top of the float chamber of the carburetter. In the old days, the position of the tank, at any rate on touring ears, was usually under the seat, and, with the high seats then in vogue, and owing to the fact that it was not at that time considered requisite that the engine induction pipe should be kept as short as possible, little difficulty was experienced in placing the carburetter so that the requisite head was available.

Refinements in the matter of body design, the fitting of deeper cushions, the lowering of the seats, 1340 and the inconvenience of having to disturb the passenger whenever additional petrol was required, resulted in its being placed at the rear end of the chassis and the use of a pressure-fed system for transferring the fuel from there to the carburetter. The requisite pressure was, as a rule, achieved either by the utilization of the exhaust gases or from a small air compressor operated either by the engine camshaft or by some similar arrangement in the gearbox. With either of these arrangements it was necessary to pump up by hand before starting the engine. Their disabilities include the existence of two long lines of small piping, and many joints under pressure, the complication of the additional air pump in the one case or back-nresmire valves in the other, both of the latter being. unfortunately, liable to occasional derangement.

In a few cases recourse was then had to placing the tAnk underneath the scuttle dash. This had the ad vantage of giving plenty of head, but was, as a general rule, an.awkward manufacturing proposition. Trouble was also experienced owing to the vibration of this rather unusual weight at such a height above the chassis frame. The rear end of the chassis as the position of the fuel tank was an attractive one, particularly for two-seater cars and also in the, case of four and five-seaters, when the back seats are unoccupied, the additional weight on the rear wheels being of considerable advantage where otherwise lack of sufficient weight for requisite adhesion might result.. For this reason, and also for reasons more particularly affecting body design, it has been found worth while, notwithstanding the known disadvantages of pressure feed, still to place the tank at the rear.

In the design of commercial vehicles these various advantages of the rear position are not SO Obvious. In the first place, the seat is generally much higher with regard to the engine than in the touring car. A long flat tank can be accommodated, lifted a considerable distance above the frame level and giving all the head likely to be required. The disadvantage of disturbing someone when the tank has to be refilled is not of any importance in this ease. There is no need for additional weight at the back, as, even when running light, there is, as a rule, quite sufficient load for adhesion on the rear axle of a commercial vehicle. Consequently, the rear end of chassis position holds no particular attraction in that respect. Further, whereas the extra care which is necessary to keep pressure-feed systems in order is not a considerable drawback on a touring car, owing to the fact that owner or driver has time to look after these minor points, it becomes a matter for serious consideration in the case of a vehicle used for commercial purposes, where time is undoubtedly money, and where any delay owing to derangement of these parts might mean the throwing out of order of a whole day's deliveries. Consequently, with one or two exceptions, gravity feed is the rule on commercial vehicles.

Oa Subsidy Models.

There are one or two instances, however, of interest to heavy enassis designers and users, where the adoption of some means other than gravity feed for the purpose in view would be of considerable advantage. The particular style of tank which is specified by the War Office for subsidy machines involves, for gravity feed, either a very high seat indeed, or the positioning of the carburetter very low down on the engine, with the inevitable increased length of induction pipe, and, what is of more importance, greater difficulty of access to the jets, etc. In chars-aabanes, also, an underseat position is to be avoided if possible, owing to the fact that with the ordinary spacing from seat to seat it considerably interferes with the comfort of the passengers in the second row, inasmuch as it occupies space which would, in other circumstances, be utilized as leg room. The objections stated to hold in the case of a touring car in the dash position for the

tank are stronger in the case of a cha,r4t-bancs, since, as a rule, the tank capacity required with these

maehines is from 25 to 30 gallons, which is nearly canal to a couple of

hundredweight of fuel alone, quite apart from the weight of a reservoir of sufficient strength to carry such a quantity.

Some other position is, therefore, advisable. It is not, of course, necessary that the tank should be placed at the extreme rear of the chassis, as this involves an excessive amount of piping, but it could very well be placed either under the step or inside the framework of the chassis. The objections to the use of pressure-feed, however, are none the less urgent in the case of chart4-bancs than in ordinary commercial vehicles, and they are of even more consequence in machines for military purposes.

,Utilizes Induction Vacuum.

More than ordinary interest is, therefore, attached to a, new system of feed which utilizes the vacuum in the engine induction pipe to draw the petrol from the tank, to a small supplementary reservoir, which may be placed in any position desired, so as to give the necessary head above the carbu retter.

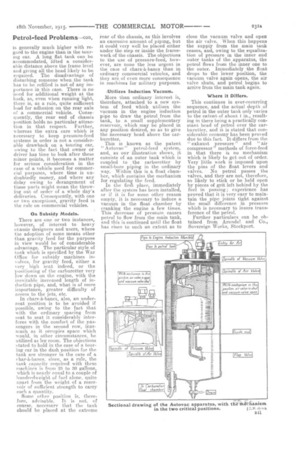

This is known as the patent " Autovac " petrol-feed system, and, as our illustration shows, it consists of an outer tank which is coupled to the carburetter by small-bore piping in the ordinary way. Within this is a float chamber, which contains the mechanism for regulating, the feed.

In the first place, immediately after the system has been installed, or if it is for some other reason empty, it is necessary to induce a vacuum in the float chamber by cranking the engine a few times. This decrease of pressure causes petrol to flow from the main tank, and this is continued until the float has risen to such an extent as to

close the vacuum valve and open the air valve. When this happens the supply from the main tan.k ceases, and, owing to the equalization of pressure in the inner and outer tanks of the apparatus, the petrol flows from the inner one to the outer. Immediately the float drops to the lower position, the vacuum valve again opens, the air valve shuts, and petrol begins to arrive from the main tank again.

Where it Differs.

This continues in ever-recurring sequence, and the actual depth of petrol in the outer tank only varies to the extent of about I in., resulting in there being a practically constant head of petrol over the carburetter, and it is stated that considerable economy has been proved due to this fact. It differs from the "exhaust pressure" and "air compressor" methods of force-feed in that there is no mechanism which is likely to get out of order. Very little work is imposed upon the pins of the float levers and valves. No petrol passes the valves, and they are not, therefore, so likely to stick or be held open by pieces of grit left behind by the fuel in passing ; experience has proved that it is very easy to maintain the pipe joints tight. against the small difference in pressure which is necessary to insure transference of the petrol.

Further particulars can be obtained from Arundel and Co., Sovereign -Works, Stockport.