BREATHING IN POWER

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

Turbocharging is one area of automotive design with plenty of scope for development. The potential rewards include cleaner, lighter, more economical and more powerful truck engines.

• Turbochargers are taken for granted on the majority of diesel-powered trucks 01 17 tonnes GVW and above, and up at the 38-tonne limit only Mercedes-Benz lists a naturallyaspirated engine.

As a result, fleet engineers who 10 or 15 years ago had reservations about blown engines no longer lie awake at night wondering when the next turbo will self-destruct. Tremendous, though largely unsung, progress in turbo reliability and endurance has been made, most of all by the American-owned Garrett and Holset companies, but Schwitzer (also American) and KKK of Germany are not far behind.

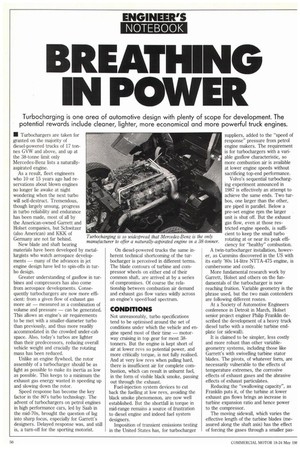

New blade and shaft bearing to offer a naturally-aspirated engine in a 38-tonner.

materials have been developed by metallurgists who watch aerospace develop ments many of the advances in jet engine design have led to spin-offs in turbo design.

Greater understanding of gasflow in turbines and compressors has also come from aerospace developments. Consequently turbochargers are now more efficient: from a given flow of exhaust gas more air — measured as a combination of volume and pressure — can be generated. This allows an engine's air requirements to be met with a smaller-diameter turbo than previously, and thus more readily accommodated in the crowded under-cab space. Also, today's turbos are lighter than their predecessors, reducing overall vehicle weight and crucially the rotating mass has been reduced.

Unlike an engine flywheel, the rotor assembly of a turbocharger should be as light as possible to make its inertia as low as possible. This keeps to a minimum the exhaust gas energy wasted in speeding up and slowing down the rotor.

Speed response has become the key factor in the 80's turbo technology. The advent of turbochargers on petrol engines in high performance cars, led by Saab in the mid-70s, brought the question of lag into sharp focus, especially for Garrett's designers. Delayed response was, and still is, a turn-off for the sporting motorist. On diesel-powered trucks the same inherent technical shortcoming of the turbocharger is perceived in different terms. The blade contours of turbine and compressor wheels on either end of their common shaft, are arrived at by a series of compromises. Of course the relationship between combustion air demand and exhaust gas flow varies wildly across an engine's speed/load spectrum.

CONDITIONS

Not unreasonably, turbo specifications tend to be optimised around the set of conditions under which the vehicle and engine spend most of their time — motorway cruising in top gear for most 38tonners. But the engine is kept short of air at lower revs so potential power, and more critically torque, is not fully realised. And at very low revs when pulling hard, there is insufficient air for complete combustion, which can result in unburnt fuel, in the form of visible black smoke, passing out through the exhaust.

Fuel-injection system devices to cut back the fuelling at low revs, avoiding the black smoke phenomenon, are now well established. But the shortfall in torque in mid-range remains a source of frustration to diesel engine and indeed fuel system designers.

Imposition of transient emissions testing in the United States has, for turbocharger suppliers, added to the "speed of response" pressure from petrol engine makers. The requirement is for turbochargers with a variable gasflow characteristic, so more combustion air is available at lower engine speeds without sacrificing top-end performance.

Volvo's sequential turbocharging experiment announced in 1987 is effectively an attempt to achieve the same ends. Two turbos, one larger than the other, are piped in parallel. Below a pre-set engine rpm the larger . unit is shut off. But the exhaust gas flow, even at those restricted engine speeds, is sufficient to keep the small turbo rotating at or near its peak efficiency for "healthy" combustion.

A twin-turbocharger installation, however, as Cummins discovered in the US with its early '80s 14-litre NTTA-475 engine, is cumbersome and costly.

More fundamental research work by Garrett, Holset and others on the fundamentals of the turbocharger is now reaching fruition. Variable geometry is the phrase used, but the two main contenders are following different routes.

At a Society of Automotive Engineers conference in Detroit in March, Holset senior project enginer Philip Franklin described the development of a heavy truck diesel turbo with a movable turbine endplate for sidewall).

It is claimed to be simpler, less costly and more robust than other variablegeometry systems, including those like Garrett's with swivelling turbine stator blades. The pivots, of whatever form, are necessarily vulnerable to the effects of temperature extremes, the corrosive effects of exhaust gases and the abrasive effects of exhaust particulates.

Reducing the "swallowing capacity", as Franklin puts it, of the turbine at lower exhaust gas flows brings an increase in turbine expansion ratio and hence power to the compressor.

The moving sidewall, which varies the effective length of the turbine blades (measured along the shaft axis) has the effect of forcing the gases through a smaller pas sage. Their speed and pressure are necessarily increased and can be more productively harnessed.

Holset has tried a number of movingsidewall configurations. The simplest was what Franklin calls a "sliding plug" — a restrictor which is moved axially to vary the throat (or nozzle) area between the turbine blades. A split seal ring had to be used to prevent gas flowing around the back of the plug. In the event, its performance was disappointing and the design proved difficult to manufacture in sufficiently robust and durable form.

The next prototype, christened the "zip fastener", used a fixed ring of blades on one side and a second axially-movable ring with its blades interspaced with those on the fixed ring. By bringing the two rings together, with falling engine speed, the blades "meshed" progressively reducing the effective throat area radially as well as axially.

Turbulence around the stub-ends of both blade rings was found to detract from the system's efficiency, but as the blade tips approached the opposite wall efficiency rose again. This implied undue complexity in the control system, whatever form of actuation was employed. Also the reduction in throat area, and hence swallowing capacity, is limited to about 50% which restricts the system's benefits in transient and part-load operation.

Undaunted, the Holset engineers tried what they called the "full shroud" concept, in which that length of the stator blades not required is enclosed on the outside and inside by an axially-movable annular ring with blade-shaped slots in it. The slots are fitted with split seals to minimise gasflow losses into the ring annulus.

An attraction of the full shroud was that it could — to use Franklin's words — be "over opened". At high engine speed and power the shroud can be withdrawn beyond the end of the turbine blades. This gives a more desirable speed/output characteristic something like that of a swivelling vane system, whereby the turbocharger is at its most efficient at smaller swallowing capacities.

Tests by Holset on the different moving-sidewall turbos and an experimental swivelling-vane unit on a Cummins L10 engine showed that turbocharger efficiency at different "swallowing" capacities could not be assessed meaningfully in isolation from the aspiration needs of the particular engine type.

At lower speeds, when swivelling-vane or full-shroud variable geometry is being implemented, engine back pressure is reduced so that for a given airflow charge air pressure need not be as high as at greater speeds. The net effect is that specific fuel consumption is likely to suffer a little at higher loads and speeds. In determining turbo specification then, a value judgement needs to be made on the relative importance of engine efficiency (as shown in performance, economy and emissions) at different horsepower and rpm levels.

Another variation on the moving sidewall theme tried by Holset was dubbed the "double-nozzle" arrangement. The turbine stator blades moved axially and incorporated a thin central dividing ring. Performance proved disappointing.

CONCLUSION

Holset's conclusion is that the full-shroud configuration is the most successful, weighted against its practicability for manufacturing. In its latest form it incorporates 1 further extrapolation of the over-opening idea. When the shroud is fully withdrawn, additional movement of the actuator pulls the stator blades out of the air stream, leaving an even bigger clearance against the opposite side wall.

Test bed trials have shown that this system matches any swivelling vane system in efficiency. Franklin readily admits that turbo development as it affects gasflow behaviour is still as much an art as a science, and that further new advances are likely to come from trial-and-error experimentation.

Just how movement of the shroud and blade are actuated is a matter for close collaboration with the engine manufacturers. The advent of electronics to control fuel-injection (CM 16-22 March) has opened the way to variable geometry turbocharging, with the same on-board microprocessor signalling inter-related "instructions" so that turbocharger and Fl characteristics achieve an optimum match.

With the continued twin impetus of emission regulations and the demand for greater power and fuel efficiency, turbocharger design will continue to evolve. Using the technology and new materials spin-offs from the aerospace industry, computer-aided designers of the future will soon be offering truck manufacturers the sort of turbocharger that will give any hard-pressed fleet engineer nothing but sweet dreams.

CI by Alan Bunting.