The speedy we

Page 186

Page 187

Page 188

If you've noticed an error in this article please click here to report it so we can fix it.

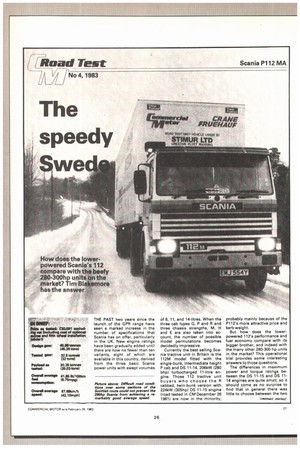

THE PAST two years since the launch of the GPR range have seen a marked increase in the number of specifications that Scania has on offer, particularly in the UK. New engine ratings have been gradually added until there are now no fewer than ten variants, eight of which are available in this country, derived from the three basic Scenia power units with swept volumes of 8, 11, and 14-litres. When the three cab types G. P and R and three chassis strengths, M. H and E are also taken into account, the number of possible model permutations becomes decidedly impressive.

Currently the best selling Scania tractive unit in Britain is the 112M model fitted with the single-bunk, intermediate height P cab and DS 11-14, 206kW (280 bhp) turbocharged 11-litre engine, Those 112 tractive unit buyers who choose the R cabbed, twin-bunk version with 224kW (305hp) DS 11-15 engine (road tested in CM December 26 1981) are now in the minority, probably mainly because of the P112's more attractive price and kerb weight.

But how does the lowerpowered 112's performance and fuel economy compare with its bigger brother, and indeed with the many other 280-300 hp units in the market? This operational trial provides some interesting answers to those questions.

The differences in maximum power and torque ratings between the OS 11-15 and DS 1114 engines are quite small, so it should come as no surprise to find that in general there was little to choose between the two Scanias' performances over CM's Scottish test route.

Both vehicles are fitted with Scania's own synchromesh gearboxes but the 280hp engine is matched to the GS770 splitter model while the more powerful, higher torque engine is coupled with the more robust GR870 range-change transmission, Which is offered as an option on the P112.

Both these gearboxes have direct top ratios and all UK spec 112s have the 3.88:1 ratio in the single reduction rear-axle as standard (though any one of seven alternative ratios is available for customers who are prepared to wait).

Operators whose vehicles frequently have to restart on steep gradients would be well advised to choose the range change gearbox in preference to the splitter model, whichever engine variant is specified simply because the GR870 has a much deeper first gear ratio, 13.15:1 compared with the GS770's 9.89:1. That gives the standard P112 only a modest restart capability at 32.5 tonnes of 1 in 5.6.

The advantages of the 0S770 are that it has no awkward-to-engage mid-range gear like the GR870's sixth, and for motorway work fourth high and fifth low are more useful ratios than the GR870's second highest (ninth).

Even over the 1 in 7 to 1 in 6 gradients of the A68 section of the Scottish route the lowest ratio needed to keep the P112 rolling was second low, and this gear could be used for moving off from rest on the level, though not when facing uphill.

The P112 shares the R112's impressive ability to maintain high average speeds over all kinds of terrain. Despite some snow showers making the road between Dalkeith and Jedburgh call for a lithe more caution than usual, which must therefore have increased the journey time slightly, the P112's overall average speed surprisingly was a mite faster than that of the R112.

Unusually light traffic in Edinburgh helped to keep the second day's journey time :short on this trial but nothing should detract from the P112's performance on the third day when, for example, over the demanding motorway section of the route between Darrington and MIRA, this Sca nia's average speed matched exactly that of the very swift 330hp Daf FT 3300 DKX.

The histograms on page 31 of this report show how the P112M compares in three important areas, with three others of its most serious 290hp competitors in Britain. With an overall average fuel consumption over the Scottish route marginally worse than the R112's, this Scania could not match the fuel economy of the Leyland, Ivaco or Seddon Atkinson models with which I have compared it, but both the hill climb table and the average speed histogram show that it can more than hold its own when journey times are critical.

As for payload, no more than a few kilograms separate this Scania from the Cummins-engined Roadtrain and Iveco 190.29 (both twin-bunk sleepers) but the Seddon Atkinson 401 stands out by virtue of its lightweight Rolls Royce engine and Americansourced lightweight chassis components.

The winter is a good season in which to road test a Scania if all its qualities are to be appreciated. In weather conditions that were sometimes not very different from those one would expect in this vehicle's country of origin, I was frequently conscious of the many features which the Swedish manufacturer considers essential to keep drivers contented.

The electrically-heated driver's seat made the first few miles after each frosty early morning start much more comfortable than they would otherwise have been and, once the engine was warmed up, which happened quite quickly thanks to the optional thermo-viscous fan fitted to the test vehicle, Scania's excellent heating and ventilation system allowed a comfortable temperature to be maintained inside the cab at all times.

The GPR range's headlights with powerful 75/70W halogen bulbs are a vast improvement over the weak lights of earlier models and the extremely useful, hydraulically operated beam height adjuster is a feature with which Scania now leads the field (though Iveco does fit a similar system to its tractive units).

For the rather slippery surfaces on some parts of the Scottish route I would have preferred to have a little more "feelthan that provided by this Scania's low-geared, power-assisted steering. The degree of power assistance, together with the low gearing (six turns from lock to lock) makes the Scania's steering rather fussy and anything but the lightest of touches causes the wheel to see-saw about the straight-ahead position.

However, it is perhaps understandable that Scania should choose to fit such light steering when it is clear that the manufacturer's general philosophy is to make all the driver's tasks as easy as possible.

Two aspects of this Scania's braking performance were disappointing though, and are not so excusable. As the results page shows, the drive axle's braking efficiency was unacceptably low and the brakes on this axle also had to be adjusted to correct an imbalance which caused premature locking on the nearside rear-wheel during our track tests. Then, on the third day of the test, on the tong descent into Corbridge the Scania's gauges began to warn of falling air pressure. By the lime I brought the vehicle to a halt the low-air warning buzzer and light were on, and no amount of engine revving would build up the air pressure.

The cause of the problem was found to be a missing bolt and broken gasket on the flange which connects the compressor to its outlet pipe. These Alienheaded bolts have a habit of working loose (one fell out on an earlier CM Scania road test) but Scania GB thought it had solved the problem by advising that the threads should be smeared with Loctite and then tightened with a torque wrench. It is clear that even this action is not enough. Perhaps it is time the bolts were wired together.

On this occasion, the replacement bolt and gasket were brought to us and fitted by Union Trucks Ltd, the Scania dealer at Darlington, and we were grateful for their prompt response.

But it was not only mechanical failures that delayed us during this operational trial — the unpredictable British weather seemed determined to play its part. At Jedburgh we were advised that the road south over Carter Bar was impassible owing to heavy snow. When we saw that even a 6x4 snowplough had a certain amount of difficulty in reaching the summit we were bound to accept the soundness of this advice. The P112 was parked up at the Scottish border town until the road was cleared and the trial could be completed.

Like every other GRP Scania I have driven, this P112 tractive unit left me unfired at the end of each working day and impressed me greatly with the attention paid by its manufacturer to comfort and safety.

Still, if I were an owner-driver of a 112, behind its wheel every day, there are some minor modifications I should wish to make.

First I would throw away the astonishingly feeble sounding standard Scania horn and replace it with a much more effective warning instrument.

Then I would wish to rewire the windscreen washer pump so that it could operate independently of the wipers and thereby lessen the risk of the windscreen being scratched simply because the wipers go through an operating cycle every time the pump is switched on even if the washer bottle be empty. And, of course I would be sure to fix securely those compressor bolts.

But would I choose the P112 in preference to the R112? That would depend on the type of operation the vehicle was to be used for but it is not difficult to see why the majority of Scania buyers in the UK favour this model.