Body fabrication techniques that cut costs

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

ANEW 5cwt. battery-operated tailboard lift and a novel type of bodywork construction, evolved by R. A. Neaverson Ltd., Abbey Lane, Leicester, are notable examples of reducing production costs by eliminating the need for skilled labour in the workshops. In the case of the tailboard lift, the maximum use is made of pre-assembled units. Features of the bodywork include a method of assembling the bolted structure that simplifies panelling, provides for easy replacement of the panels and adds to the strength of the body. The structure could readily be exported in CKD form.

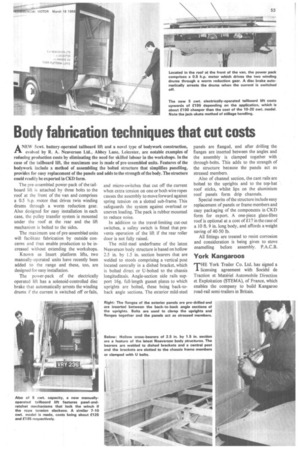

The pre-assembled power-pack of the tailboard lift is attached by three bolts to the roof at the front of the van and comprises a 0.5 h.p. motor that drives twin winding drums through a worm reduction gear. Also designed for easy installation in each case, the pulley transfer system is mounted under the roof at the rear and the lift mechanism is bolted to the sides.

The maximum use of pre-assembled units will facilitate fabrication by outside concerns and thus enable production to be increased without extending the workshops.

Known as Insert platform lifts, two manually-operated units have recently been added to the range and these, too, are designed for easy installation.

The power-pack of the electrically operated lift has a solenoid-controlled disc brake that automatically arrests the winding drums if the current is switched off or fails, and micro-switches that cut off the current when extra tension on one or both wire ropes causes the assembly to move forward against spring tension on a slotted sub-frame. This safeguards the system against overload or uneven loading. The pack is rubber mounted to reduce noise.

In addition to the travel-limiting cut-out switches, a safety switch is fitted that prevents operation of the lift if the rear roller door is not fully raised.

The mild.steel underframe of the latest Neaverson body structure is based on hollow 2.5 in. by 1.5 in. section bearers that are welded to stools comprising a vertical post located centrally in a dished bracket, which is bolted direct or U-bolted to the chassis longitudinals. Angle-section side rails support 16g. full-length gusset plates to which uprights are bolted, these being back-tohack angle sections. The exterior mild-steel panels are flanged, and after drilling the flanges are inserted between the angles and the assembly is clamped together with through-bolts. This adds to the strength of the structure because the panels act as stressed members.

Also of channel section, the cant rails are bolted to the uprights and to the top-hat roof sticks, whilst lips on the aluminium roof panels form drip channels.

Special merits of the structure include easy replacement of panels or frame members and easy packaging of the components in CKD form for export. A one-piece glass-fibre roof is optional at a cost of £17 in the case of a 10 ft. 9 in. long body, and affords a weight saving of 40-50 lb.

All fittings are treated to resist corrosion and consideration is being given to stove enamelling before assembly. P.A.C.B.