An Opposed-piston Two-stroke Engine

Page 200

If you've noticed an error in this article please click here to report it so we can fix it.

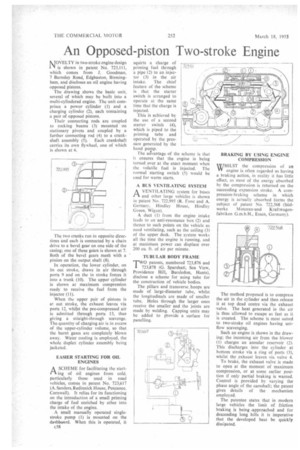

MOVELTY in two-stroke engine design I is shown in patent No. 723,111, which comes from J. Goodman, 7 Barnsley Road, Edgbaston, Birmingham, and discloses an oil engine having opposed pistons.

The drawing shows the basic unit, several of which may be built into a multi-cylindered engine. The unit cornprises a power cylinder (1) and a charging cylinder (2), each containing a pair of opposed pistons.

Their connecting rods arc coupled to rocking beams (3) mounted on stationary pivots and coupled by a further connecting rod (4) to a crankshaft assembly (5). Each crankshaft carries its own flywheel, one of which is shown at 6.

The two cranks run in opposite threedons and and each is connected by a chain drive to a bevel gear on one side of the casing; one of these gears is shown at 7. Both of the bevel gears mesh with a pinion on the output shaft (8).

In operation, the lower cylinder, on its out stroke, draws in air through ports 9 and on the in stroke forces it into a trunk (10). The upper cylinder is shown at maximum compression ready to receive the fuel from the injector (11).

When the upper pair of pistons is at out stroke, the exhaust leaves via ports 12, whilst the pre-compressed air is admitted through ports 13, thus giving a straight-through scavenge. The quantity of charging air is in excess of the upper-cylinder volume, so that the burnt gases are completely blown away. Water cooling is employed, the whole duplex cylinder assembly being jacketed.

EASIER STARTING FOR OIL ENGINES

A SCHEME for facilitating the starting of oil engines from cold. particularly those used in road vehicles, comes in patent No. 723,617 (A. Sanders, Redinnick House, Penzance, Cornwall). It relies for its functioning on the introduction of a small priming charge of fuel enriched by ether into the intake of the engine.

A small manually operated singlestroke pump (1) is mounted on the dashboard. When this is operated, it c58 squirts a charge of priming fuel through a pipe (2) to an injector (3) in the air intake. The chief feature of the scheme is that the starter switch is arranged to operate at the same time that the charge is injected.

This is achieved by the use of a second starter switch (4), which is piped to the priming tube and operated by the pressure generated by the hand pump. The acrvantage of the scheme is that it ensures that the engine is being turned over at the exact moment when the volatile fuel is injected. The normal starting switch (5) would be used for warm starts.

A BUS VENTILATING SYSTEM

AVENTILATING system for buses and other large vehicles is shown in patent No. 722,995 (R. Fone and A. Gernacy. HindleyHouse, Hindley Green. Wigan).

A duct (I) from the engine intake leads to an anti-resonance box (2) and thence to such points on the vehicle as need ventilating, such as the ceiling (3) of the upper deck. The system works all the time the engine is running, and at maximum power can displace over 200 Cu, ft. of air per minute.

TW723TUBULAR BODY FRAME ,878 (G. Sparshatt, Sea View, 0 patents, numbered 723,876 and

Providence Hill, Bursledon, Hants), disclose a scheme for using tube for the construction of vehicle bodies.

The pillars and transverse, hoops are made of large-diameter tube, whilst the longitudinals are made of smaller tube. Holes through the larger ones receive the smaller and the joints are made by welding. Capping units may be added to provide a surface for panelling. BRAKING BY USING ENGINE COMPRESSION

WHILST the compression of an engine is often regarded as having a braking action, in reality it has little effect, as most of the energy absorbed by the compression is returned on the succeeding expansion stroke. A compression-braking scheme in which energy is actually absorbed forms the subject of patent No. 722,568 (Slid werke Motoren-und Kraf twagenfabriken G.m.b.H., Essen, Germany).

The method proposed is to compress the air in the cylinder and then release it at top dead centre via the exhaust valve. The heat generated in the air is thus allowed to escape as fast as it is created. The scheme is most suited to two-stroke oil engines having uniflow scavenging.

Such an engine is shown in the drawing; the incoming air from the blower (1) charges an annular reservoir (2). This discharges into the cylinder at bottom stroke via a ring of ports (3), whilst the exhaust leaves via valve 4.

To brake, the exhaust valve is made to open at the moment of maximum compression, or at some earlier position if only partial braking is wanted. Control is provided by varying the phase angle of the camshaft; the patent gives details of the mechanism employed.

The patentee states that in modern large vehicles the limit of friction braking is being -approached and for descending long hills it is imperative that the developed heat be quickly dissipated.