Towards an Ideal in Cleansing

Page 123

Page 124

Page 125

If you've noticed an error in this article please click here to report it so we can fix it.

By

Alan Smith

P-1LEANSING engineers' constant demands for efficient machines 6•-/and the. complexities of their sks have given wide scope to the )ntribution of ingenious ideas in .e design of municipal vehicles. lanufacturers early devoted their tention to local authorities' special :eds and municipalities, in their rn, were quick to adopt the motor hick.

At the turn of the century it was timated that one steam wagon mid do the work of six horse-drawn ,rts. One authority saved £175 a ;ar per steamer employed in place horses. Chelsea had a fleet of 15 yland steam tippers. Probably the most recurrent call Ls been for a vehicle which lends elf to the interchange of different pes of bodywork, and nong the first makers to iswer it were John I.

lornycroft and Co., Ltd, heir catalogue for 1905 ;scribed the range of earners offered, and nong them was a tipper, e body of which could removed and replaced ith a sprinkler tank in a w minutes. The tank was said to be made of "the finest torpedo-boat steel" and its capacity was 700 gallons. The valves were operated by pedals.

Thornycroft made a sprinklersweeper similar to the tank vehicle, but having in addition a revolving brush or rubber squeegee at the rear. Their simple tipping refuse collection body could carry up to 4 tons, but a " Colonial" type was built for 5 tons. Special bodywork was made for the collection of sanitary bins, shelves being arranged inside the box body, with "close-fitting door," for 100 receptacles.

Attempts to evolve the universal municipal appliance continued. Some 20 years later, Dennis Bros., Ltd., produced a tipper with an open steel body, at the rear of which was a pair of doors. These were hinged so as to swing clear of the body aperture for unimpeded discharge.

In such a form, the vehicle could be used for refuse disposal, but for the collection of night soil, a 200gallon tank could be mounted at the rear. Contents of latrine receptacles were emptied into the tank, and the vehicle, which cost £480, found some use in rural districts where suctiontype emptiers could not be employed.

However, steps in the direction of the ideal multi-purpose vehicle have not, except perhaps in the case of the mechanical horse and semitrailer principle, reached their goal, and, indeed, it is hard to define what that goal should be. Not only are the technical difficulties great, but municipal authorities' requirements and specifications vary widely.

The industry's efforts have thus been more to improve the efficiency of vehicles designed for one function only, although tank vehicles which could be used for two or more of the purposes for street sprinkling, gully and cesspool-emptying, and firefighting were common in the days following the 1914-1918 war.

Hygiene dictated that open refuse. collection bodies be fitted with canvas canopies, and by the 1920s steel sliding shutters had become familiar. In 1928, the Eagle Engineering Co., Ltd., produced a dustless refuse collector. This had a revolving tank with four filling ports into which fitted the rims of upturned dustbins. The tank was rotated to compress the load and tipped for discharge.

Another Eagle design of this year was a trailer with a rotating framework on which dustbins could be placed to be taken away for emptying at a tip or incinerator, empty bins being carried to replace those picked up as the outfit went on its rounds.

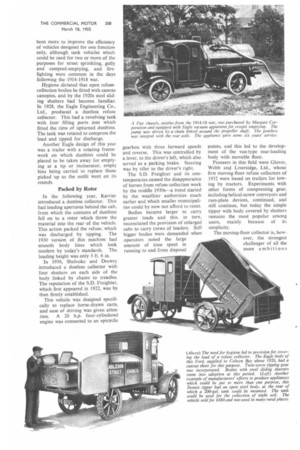

Packed by Rotor In the following year, Karrier introduced a dustless collector. This had loading apertures behind the cab, from which the contents of dustbins fell on to a rotor which threw the material into the rear of the vehicle. This action packed the refuse, which was discharged by tipping. The 1930 version of this machine had smooth body lines which look modem by today's standards. The loading height was only 3 ft. 6 in.

In 1936, Shelvoke and Drewry introduced a dustless collector with four shutters on each side of the body linked by chains to treadles. The reputation of the S.D. Freighter, which first appeared in 1922, was by then firmly established.

This vehicle was designed specifically to replace horse-drawn carts, and ease of driving was given attention. A 20 h,p. four-cylindered engine was connected to an epicyclic gearbox with three forward speeds and reverse. This was controlled by a lever, to the driver's left, which also served as a parking brake. Steering was by tiller to the driver's right.

The S.D. Freighter and its contemporaries caused the disappearance of horses from refuse collection work by the middle 1930s—a trend started by the wealthier authorities much earlier and which smaller municipalities could by now not afford to resist.

Bodies became larger to carry greater loads and this, in turn. necessitated the provision of enlarged cabs to carry crews of loaders. Still bigger bodies were demanded when operators noted the large amount of time spent in running to and from disposal points, and this led to the development of the van-type rear-loading body with movable floor.

Pioneers in this field were Glover, Webb and Liversidge, Ltd., whose first moving-floor refuse collectors of 1932 were based on trailers for towing by tractors. Experiments with other forms of compressing gear, including helical-screw conveyors and ram-plate devices, continued, and still continue, but today the simple tipper with body covered by shutters remains the most popular among users, mainly because of its simplicity.

The moving-floor collector is, however, the strongest challenger of all the more ambitious

(Right) This 1928 Karrier chassis had an Eagle dustless refuse-collection body in the form of a tank with four filling ports. The tank was rotated to compress the load and tipped for discharge. Dustbins used in conjunction with the vehicle had hinged lids which engaged with the filling ports to ensure dust-free loading. (Below) The S.D. Freighter appeared in 1922 and was specially designed for easy control by drivers of horsed carts. The system of steering, braking and gearchanging remained in use for 17 years.

forms of appliance, and now that problems of bulk refuse disposal by road face many municipalities, its development may well further be advanced.

Concurrent with improvements in refuse collectors ran the evolution of the street sweeper. Internal-combustion-engined sweepers first appeared in 1910, and seven years later the Lacre Motor Co. produced an innovation in this line—a vehicle with brushes disposed ahead of the rear axle and having an elevator to pick up sweepings and deposit them through a hopper into the body.

In 1920, Lacre made their L-type three-wheeled sweeper with chaindriven brush gear which could quickly be detached and replaced by a squeegee or snow-plough.

Karrier's early approach to sweeper design was typified by their 1920 model, which incorporated sprinkler equipment. Road refuse was first wetted so that its collection by the pan and conveyor device would be dustless. The Karrier had two fullwidth brushes, one behind each axle. The rear brush was of larger diameter than the front and when worn could be transferred to the leading position.

The rear wheels were also larger than the front, and second gear was in direct drive. This allowed quiet running for sweeping operation at 5 m.p.h., whilst higher indirect gear could be engaged for travelling to the tip.

Newcastle upon Tyne bought a Karrier sweeper and found that it performed the work previously done by four men, a pony cart and two horse-drawn brushes working five nights a week.

Some cost figures published at the time of the introduction of the machine are interesting. It was claimed that whereas horse-drawn sweepers cost £63 per week to clean 45 miles of road, a Karrier cost only £22 10s., expenses including driver's wage at £3 10s., petrol at 3s. a gallon and an allotment of £5 for brush replacement.

The Yorkshire Patent Steam Wagon Co., a company with whom Karrier made a manufacturing arrangement in 1936, devoted themselves largely to the design of gully and cesspit emptiers. Their first model was produced in 1915 for Chiswick and was based on a steamer chassis of their own make.

A 1924 Yorkshire appliance, built for St. Pancras, had a water compartment, as well as a sludge container, for resealing drains. Apparatus made later upon Karrier chassis comprised a tank in which there was a central tube for receiving sludge, whilst the annular compartment around it held sealing water.

Many ex-Army vehicles of the 1914-1918 war were being sold on the civilian market around this period and some went into municipal service.

Pump Before Radiator Dennis gully-emptiers of this time were among the first to include an adaptation for street sprinkling. A turbine pump, mounted in front of the radiator, was connected to the crankshaft of the engine through a clutch. Two fan-shaped nozzles were disposed at the front and water was discharged through slots, rather than perforations, up to a width of 40 ft. A combined gully-emptier and street-washer cost £1,560.

Perhaps the most notable development in recent years in the progress of the municipal vehicle has been the growing adoption of the oil engine. The fable that such a power unit is economic only for vehicles that cover large mileages has been disproved, and many operators have come to appreciate its reliability.