MAKING BEST USE OF THE FORD.

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, Which Will Appeal to the Owner, Driver and Repairer.

IN THIS series of hints concerning the Ford light chassis and ton truck wherever they are employed for commercial purposes, we endeavour to deal with the subject from every view-i■oint, so that the advice given will appeal to the owe,er, driver, maintenance engineer, or mechanic. Valuable sources of information are being tapped for this purpose, and it should be understood that the advice given will be derived from those with an intimate knowledge of the sub j ect. We shall welcome for inclusion among. the hints those which have proved of value to individual users, and will make suitable remuneration for any published. What we desire are the results of practice.

Readers are recommended to obtain the original ".Book of the Ford," which constitutes a complete manual dealing with the Ford car, the van and the truck. 2s. 9d. post free from the offices of this journal.

181.—Protecting the Commutator Pipes.

Hot oily vapour from the breather pipe often soaks through the loom wires leading to the commutator and causes the insulation to perish. Trouble is also sometimes experienced during a downpour of rain,

. as the water runs under the bonnet support, which is fixed on the chassis frame, and causes short-circuiting in the wires.

In order to prevent these troubles, one of our readers fitted a new arrangement consisting of a piece of 3-16 in steel bent in the manner illustrated, and of such a length as to suit the cylinder head. Measurements were taken between the second and fourth bolt on the cylinder head, and two pieces of sheet-steel, 4 ins, long, about 1 in. wide and made of 1-16 in. material, were then welded at the correct distance apart on this rod.

Each upright was bent over for 1 in. at the bottom and a 7-16 in. hole drilled in the foot thus formed, and through which the cylinder head bolt could pass. After fitting, the loom wires were wound round the rod and covered with insulating tape as a preventive against slipping due to vibration. By carrying wires in this manner it has been found that they are kept quite clean and dry as they clear the breather pipe by some 3 ins.

182.—Removing the Rear Wheels of the Ton Truck.

A method of removing the rear wheels fromthe ton Ford which has proved effective in many cases wherethe usual type of wheel puller has failed, or by the roadside where such pullers have been unobtainable, is first to slacken the axle shaft nut for a few threads, and then to insert a steel bar about

5 ft. long and 1?-, ins. diameter (an old drive shaft will do) between the rim and the rear radius rod, getting a purchase in the fork of the rod. Pull on the end of this bar, at the same time giving the nut a few sharp taps with a fairly heavy hammer, being careful to give straight blows, so that no damage will be done, to the threads.

This method of removing the wheel is stated never to fail, but so far as roadside repair is concerned we hardly think that many Ford drivers would be found in possession of a steel bar of the length required.

183.—The Blublaze Commutator.

The concessionnaires for the Blublaze commutator, S. Guiterman and Co., Ltd., 35-36, Aldernaanbury, London E.C.2, have drawn our attention to article No. 170, published in our issue for February 26th, and entitled, "Curing a Trouble in a Blublaze Commutator!' It is pointed out by them that the brush iinit of this commutator is designed, and the brush is made sufficiently long, to ensure contact all othe while the brush can be used. As a matter of fact, if a brush be worn right down the device as so arranged that the metal of the brush unit comes into contact with the trackway, and at once gives an intimation that a new brush is required. The fault which we commented on is probably due to some lack of standardization in the camshaft of the particular Ford to which this timer was fitted, as from time to time slight variations from standard occur in certain details.

184.—A Useful Extra-air Device.

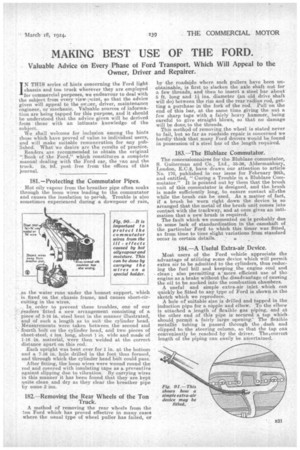

Most users of the Ford vehicle appreciate the advantage of utilizing some device which will permit extra air to be admitted to the cylinders, thus reducing the fuel bill and keeping the engine cool and clean ; also permitting a 'more, efficient use of the engine as a brake without the disadvantage of causing the oil to be sucked into the combustion chambers.

A useful and simple extra-air inlet which can quickly be fitted to any type of Ford is shown in the sketch which we reproduce. A hole of suitable size is drilled and tapped in the induction pipe for a nipple and elbow. To the elbow is attached a length of flexible gas piping, and at the other end of this pipe is secured a tap which should permit a fairly large opening: The flexible metallic • tubing is passed through the . dash and clipped to the steering column, so that the tap can conveniently be reached by the driver. The.icorrect length of the piping can easily be ascertained.