BEDFORD LACRE TG COMPACT ROAD SWEEPER

Page 61

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

by Gibb Grace, DauE, CEng, MIMechE

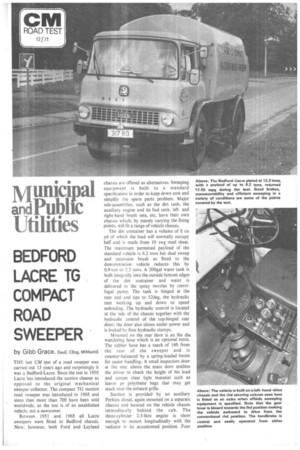

THE last CM test of a road sweeper was carried out 13 years ago and surprisingly it was a Bedford-Lacre. Since the test in 1958 Lacre has introduced the suction cleaner as opposed to the original mechanical sweeper-collector. The compact TO suction road sweeper was introduced in 1968 and since then more than 700 have been sold worldwide, so the test is of an established vehicle, not a newcomer.

Between 1951 and 1968 all Lacre sweepers were fitted to Bedford chassis. Now, however, both Ford and Leyland chassis are offered as alternatives. Sweeping equipment is built to a standard specification in order to keep down cost and simplify the spare parts problem. Major sub-assemblies, such as the dirt tank, the auxiliary engine and its fuel tank, leftand right-hand brush sets, etc, have their own chassis which, by merely varying the fixing points, will fit a range of vehicle chassis.

The dirt container has a volume of 8 cu yd of which the load will normally occupy half and is made from 10 swg steel sheet. The maximum permitted payload of the standard vehicle is 6.2 tons but dual sweep and extension brush as fitted to the demonstration vehicle reduces this by 0.9-ton to 5.3 tons. A 200gal water tank is built integrally into the outside bottom edges of the dirt container and water is delivered to the spray nozzles by centrifugal pump. The tank is hinged at the rear end and tips to 52deg, the hydraulic ram working up and down to speed unloading. The hydraulic control is located at the side of the chassis together with the hydraulic control of the top-hinged rear door; the door also closes under power and is locked by four hydraulic clamps.

Mounted on the rear door is an 8M dia wandering hose which is an optional extra. The rubber hose has a reach of 14ft from the rear of the sweeper and is counter-balanced by a spring-loaded boom for easier handling. A small inspection door at the rear above the main door enables the driver to check the height of his load and scrape clear light material such as leaves pr polythene bags that may get stuck over the exhaust grille.

Suction is provided by an auxiliary Perkins diesel, again mounted on a separate chassis and located on the vehicle chassis immediately behind the cab. The three-cylinder 2.5-litre engine is short enough to mount longitudinally with the radiator in its accustomed position. Four V-belts drive the suction fan and another belt drives the water and hydraulic pumps of the sweeping equipment. Power for tipping and for operating the rear door is provided by a pto from the vehicle engine. The auxiliary engine is supplied from a separate 13fgal tank and thus qualifies for the untaxed red fuel.

A substantial casting forms another sub-assembly; this part sits astride the main vehicle chassis and tows the right-or left-hand sweeping gear or both; it also provides attachments for the angled extension brush when fitted. The sweeping gear is mounted on a three-wheeled trolley which can be raised and lowered remotely from inside the cab. Three wheels ensure the optimum surface contact regardless of camber.

The all important gutter brush is hydraulically driven at a constant speed regardless of vehicle speed but the set speed may be varied by a hand-control valve to suit conditions. The brush is free to swing and rise and fall on its mounting but because of its weight and direction of rotation, tends to take up the lowest and outermost position.

In this way small deviations, up to 12in., from the kerb are catered for and save the driver having to religiously follow every kerbside irregularity. The suction head is mounted behind the brush and this brush/suction head combination will sweep a width up to 3.5ft from the kerb. An hydraulically driven angled extension brush can be ordered as an optional extra and this serves to direct dirt into the suction head and extend the swept width to 6.5ft.

The controls for the auxiliary engine and the sweeping equipment are neatly arranged in a central console next to the driver; the instruments include fuel tank level, oil pressure and coolant gauges. A built-in safety feature ensures that the engine will not run if the oil pressure drops below 201b /in.' or the coolant temperature exceeds 210 deg F.

Dirty roads are hard to come by in the Hatfield area as all sweepers are road tested locally before delivery and we had to go quite a way to find suitable sections of road. The chosen sections were two sides of the same road and part of a dual carriageway Class 1 road. It had rained the night before the test and although the day was bright and sunny a lot of surface water stood in the gutters of the first section. Because of the road camber and bad -drainage, this section was very dirty, the other side of the road, section two, by comparison was only about half as bad. The Class 1 road, section three, was dry and had only light dirt and occasional shingle close up to the kerb. Each section was 1.2 miles long.

The operational test was very short, the total time on the road being 2hr and the time spent sweeping lhr 18min, the balance being spent running between 'the depot and sweeping areas, but it was long enough to form definite impressions. Section A was swept in first gear all the way with the vertical scarifying brush and transverse brush in use. At the start of this section there was a gradient of about 1 in 10 and I noticed a certain amount of surging in the progression of the vehicle. I pointed this out to the Lacre driver, who drove during all the tests, but he was not perturbed about it; he was driving using the accelerator whereas normally a driver would turn up the idle control and drive without the use of the accelerator. We tried this technique but it did not stop the surging; on later sections at higher speeds and drier roads progression was uninterrupted and very smooth.

The driver habitually hung out of the window and infrequently stood up in the seat. He demonstrated that he could drive perfectly well sitting down with the mirrors provided, as in rain, but preferred to see direct. On this section although the soil was up to 2 or 3m. deep in the fillet, the brush gouged it out most effectively. The brush stalled from time to time when forced hard against the kerb but I did not see it stalled just by dirt, hard-packed clay forced the steel bristles, though very tough, to bend away or to lift the brush up rather than stall the motor. The amount of dirt on the road • was such that where the kerb was low a significant amount of dirt was thrown onto the pavement.

The most surprising fact of this part of the test, for me, was the noise level in the cab; the noise was remarkably low in spite of the fact that I was sitting sandwiched between the truck engine below and the auxiliary engine right behind. The frequencies were low rather than high and did not hurt the ears. Normal speech across the cab inside the vehicle was easy; on the pavement, the noise level was very high and we found it impossible to talk coherently walking beside the vehicle.

However, at a distance of, say, 20yd on an open road, the noise level was very much lower and not unpleasant. This first 1.2-mile section was covered in 39min, ie at 1.85 mph. In spite of the amount of dirt on this section it was swept remarkably clean, and only the very worst parts could have been improved upon. Section B was drier and much less dirty. As a result, 2nd gear was used for a large part of the time and the speed went up. One part of this section was completely dry and we tried sweeping without water; a lot of dust was kicked up but sweeping efficiency did not suffer. This section was completed in 26min. 2.8 mph.

The third and last section, C, was fast, open dual carriagewaywith only very light, mainly fine shingle dirt. This was swept in third gear with the speedometer registering 10 mph for most of the time. The 1.2 miles was covered in 13min giving a true average of 5.5 mph. This stretch was drained and completely dry and swept very clean in spite of the much higher speed. Towards the end of this section the red warning light came on indicating that the 200gal water tank was empty. The tank had lasted 3.5 miles or 11hr of operation. We continued to the end of the section, raised the brushes, then filled up at a kerbside hydrant and drove back to the weighbridge.

The gross weight had increased by 4.312 tons but this did, of course, include 400gal of water or 1.785 ton. We had picked up

2.537 tons of dirt and surface water in 1.3hr and 3.6 miles. As an average this represents 1.95 ton /hr or 0.705 ton/mile but in fact about two-thirds of this must have been picked up on the first section giving 2.6 tan /hr or 1.41 ton /nil. Filling took about 10 mm from a gravity tank and 4imin from the hydrant. The tank could not be filled at full pressure from the hydrant as it spilled out of the overflow. Separate consumption figures over the three sections were not taken but average for the 2hr test was 13 mpg. The auxiliary engine had consumed 3gal in 1.3hr giving 2.3 gal /hr.

Braking was adequate and would have improved under full load as the rear wheels locked very early. The , unusually heavy braking in the tests caused some spillage of payload back through the suction boxes. The gearbox ratios are well spaced enabling an adequate road performance, so necessary now that loads of dirt have to be carried some miles to the dump. A fuel consumption run over a measured six-mile mixed town and country route gave 12.55 mpg at an average speed of 26.8 mph.

The Bedford-Lacre sweeper will be regarded by some as a "premium” vehicle—certainly the quality of the product is very obvious at a glance, but I feel that long-term investments of this type deserve the best specification and that the extra expense incurred will pay off in highly productive troublefree work.