Economics of Mechanical Handling

Page 58

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

for Hauliers

Solving the Problems of the Carrier

IN an article which appeared in The Commercial Motor on June 4, I gave some figures for terminal delays, showing how costly they could be. I gave examples relating to the use of both 15-ton and 5-ton vehicles. For the former, terminal delays totalled from one to three hours and for the latter I assumed that the minimum was still half-an-hour at each end with a maximum of two hours. In the case of the larger vehicle I demonstrated that the difference in terminal delays increased the cost of transport by 4s. 3d. per ton, and in the case of the small vehicle as much as 4s. 7d. per ton.

I made the subject wider in its interest by assuming two lengths of lead-100 miles and 200 miles. The difference in length of lead had no influence on the increase in the cost of the terminal delays, as might be expected, because the time spent in loading and/or unloading was not in any way affected by the distance between the terminal points. Times taken for each journey were such that, in the case of the long lead the larger vehicle could make two • complete journeys per working week, but the 5-tonner was able to make three. I 'did not, however, deal with that aspect of the matter in the article, being interested only in the matter of terminal delays and their cost.

Extra Cost Involved .

For my present purpose, however, I must make provision for the extra cost involved in subsistence payments and, possibly, some extra payment for the parking or garaging of the vehicle. A fair and adequate payment is £1 10s. for the 15-tonner, each time; making £3 in all, and £4 10s. for the smaller machine, which makes three journe!,s per week as compared with two by the other. In the case of the larger vehicle, the cost per trip was shown to be £34 16s when the terminal delays were assumed to be half-an-hour each end. For the week, therefore, the cost must now be reckoned as twice that amount plus £3 for expenses. The total is £72 12s., or £2 8s. 40. per ton. With terminal delays at the maximum, the total, calculated in the same way, will he £37 19s. 4d. plus £1 10s. per journey or £78 18s. 8d. in all. The difference is £6 6s. 8d. per week. That difference will remain the same even if the !cad be shorter for, as shown in the previous article, terminal delays arc not affected by the distance travelled, B24 but only by the times taken to load and unload. That extra cost is practically the maximum saving that can be effected because the minimum allowance of half-an-hour each end is irreducible.

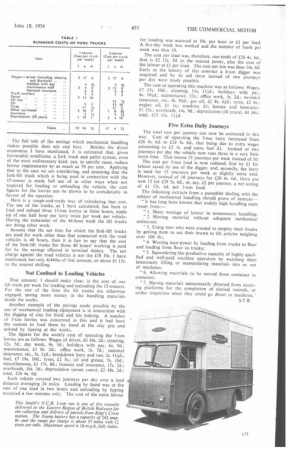

Accepting mechanical handling as a solution of the terminal delay problem, I turn now to some figures passed on to me concerning the operation of fork-lift trucks of the most suitable type for unloading or loading a 15-ton lorry, the goods being of a kind convenient to carry in high-sided pallets. The data arc given in Table I.

The cheaper of the two types of lift truck, the one having an oil engine, costs i17 4s. 72d. per week. Two such trucks are necessary to handle the traffic, one at each end of the journey, so that the minimum expenditure involved is £34 95. *I. per week. That is to compare with a total terminal loss of £6 6s. 8d. per week, the vehicle doing two journeys per week.

Economy With Three Vehicles

The use of this type of mechanical handling in connection with this particular job will not be economical until we come to a point at which three vehicles are employed, each doing two journeys per week. The saving in that case is six times £6 6s. 8d. which is £38.

That sum represents the gross total to be balanced against terminal losses which would be incurred if there were no fork-lift equipment available. Such equipment would save a total of five hours per journey. Without lift trucks and assuming that the terminal times are three hours each end per trip with trucks, the total would be one hour per trip.

Now consider the case when, the same equipment being available, the lead distance is 100 miles instead of 200. The difference between the minimum and maximum times for the terminals will stay the same, i.e., five hours per trip. The number of trips per week per vehicle will novli be three instead of two and the total times at terminals will beminimum, three hours, and maximum, 15.

The cost of those delays will still be £3 3s. 4d. per hour or £47 10s. for the 15 hours. The cost of operating two lift trucks, one at each end of the journey, will still be about £18 10s. each, or £37 per week in all. Therefore. for an expenditure of £37 per week on lift trucks the operator saves £47 10s. per week less £37 which is LIG 10i. ' The full tale of the savings which mechanical handling

makes possible does not end here. Besides the direct economies I have mentioned, it is estimated that, given favourable conditions, a fork truckand pallet system, even of the most rudimentary kind, can, in specific cases, reduce labour requirements by as much as 70 per cent. Applying that to the case we are considering, and assuming that the fork-lift truck which is being used in connection with the 15-tonner is made full use of in other ways when not required for loading or unloading the vehicle, the cost figures for the lorries can be shown to be considerably in favour of the operator.

• Here is a rough-and-ready way of calculating that cost. The use of the trucks, as I have calculated, has been to load and unload three I5-ton lorries in three hours, made .up of one half hour per lorry twice per week per vehicle, During the remainder of the 44-hour week the lift trucks are doing other work.

Assume that the net time for which the fork-lift trucks are used for work other than that connected with the road vehicles is 40 hours, then it is fair to say that the cost of the fork-lift trucks for those 40 hours' working is paid for by the savings effected in terminal delays. The net charge against the road vehicles is not the £18 10s. I have mentioned, but only 4144ths of that amount, or about £1 15s. to the nearest shilling.

Not Confined to Loading Vehicles ,

That amount, I should make clear, is the cost of one lift truck per week for loading and unloading the 15-tonners. For the rest of the time the lift trucks are otherwise engaged, saving more money in the handling materials inside the works.

Another example of the savings made possible by the use of mechanical loading equipment is in connection with the digging of clay for brick and tile making. A number of 5-ton lorries was concerned in this and it had been the custom to load them by hand at the clay pits and unload by tipping at the works.

The figures for the weekly cost of operating the 5-ton lorries are as follows; Wages of driver, £6 10s. 2d.; cleaning, 12s. 5d.; day work, 9s. 5d.; holidays with pay, 6s. 9d.; maintenance, £1 Os. 2d.; office work, 5s. 7d.; national insurance, etc., 5s. lid.; breakdown lorry and van, 2s. 'lid.; fuel, £7 19s. 10d.; tyres, £2 5s.; oil and grease, 7s. IN1.; miscellaneous, 11 17s. 8d.; licences and insurance, 17s. 2d.; overheads, 16s. 3d.; depreciation (seven years), £2 I8s, 2d.; total. £26 4s. 6d.

Each vehicle covered two journeys per day over a lead distance averaging 24 miles. Loading by hand was at the rate of one load in two hours and unloading by tipping occupied a few minutes only. The cost of the extra labour

for loading was assessed at 10s. per hour or £1 per load. A live-day week was worked and the number of loads per week was thus 10.

The cost per load was, therefore, one-tenth of £26 4s. 6d.. that is £2 12s. 5d. to the nearest penny, plus the cost of the labour at £1 per load. The cost per ton was thus 14s. 6d. Early in the history of this contract a 4-ton digger was acquired and by its aid three instead of two journeys per day were made possible.

The cost of operating this machine was as follows: Wages, £7 15s. 10d.; cleaning, I Is. 1 lid.; holidays with pay, 4s. lOid.; maintenance, 12s.; office work, 5s. 2d.; national insurance, etc., 4s. 9id.: gas oil, £2 8s. 61.d.; tyres, £2 6s.; engine oil, £1 Is.; sundries, £1; licence and insurance. £1 13s.: overheads, 14s. 9d.; depreciation (10 years), £4 16s.; total. £23 13s. II Id.

Five Extra Daily Journeys

The total cost per journey can now be estimated in this way. Cost of operating the 5-ton lorry increased from £26 4s. 6d. to £29 5s. 6d., that being due to extra wages amounting to £2 Is. and extra fuel £1. Instead of two journeys per day the vehicle now runs three in a very little more time. That means 15 journeys per week instead of 10.

The cost per 5-ton load is now reduced, first by £1 for labour saved by use of the digger, and, secondly, the lorry is used for 15 journeys per week at slightly extra cost. However, instead of 10 journeys for 126 4s. 6d., there are now 15 for £29 5s. 6d., or, say, £2 per journey, a net saving of £1 12s. 6d. per 5-ton load.

The following extracts from a pamphlet dealing with the subject of mechanical handling should prove of interest: " It has long been known that unduly high handling costs result from: " 1. Sheer wastage of labour in unnecessary handling; " 2. Moving material without adequate mechanical assistance; "3. Using men who were created to employ their brains by getting them to use their brawn to lift articles weighing over 100 lb.; "4. Wasting man-power by loading from trucks to floor and loading from floor to trucks; "5. Squandering the productive capacity of highly qualified and well-paid machine operators by watching them laboriously lifting or manipulating materials into or out of machines: "6. Allowing materials to be moved from container to container; "7. Having materials unnecessarily diverted from receiving platforms for the completion of clerical records, or undue inspection when they could go direct to machines. ' S.T.R.