M ANY operators use tippers of all-steel construction for all-purpose work

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

and then wonder why the bodies disintegrate after a few months' service. The manufacturers are often blamed for bad design or poor workmanship, but in most cases the real fault lies with the operator. Unless he specifies at the time of ordering the vehicle for what purpose he intends to use it, he can hardly expect to get the right equipment for the job.

The steel tipping body, in standard form, is now well established, and still gaining in popularity. Many specialized types of body can be obtained to suit dilrering requirements, and to choose the correct one for the operator's needs is essential. A standard body is not a maid-of-all-work, and will 1_-o more withstand misuse than will any other equipment.

When an operator requires a tipping body it is for him and the supplier to get together and discuss the ideal type for his purposes. If necessary, the bodymaker's representative should be called in, and he will ensure that only the most suitable body is ordered at the lowest possible cost, even to the extent of specifying an entirely new type.

In the words of Mr. A. F. E. Hole_ sales director of Anthony Hoists, Ltd.: "If only the operator, the dealer and the manufacturer could be brought into closer cooperation, I am confident that operators could obtain far better service from their equipment and much needless expense could be avoided."

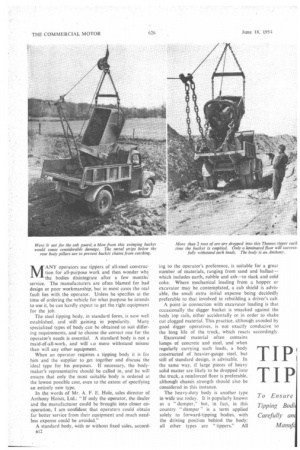

A standard body, with or without fixed sides, accorda12 ing to the operator's preference, is suitable for a great number of materials, ranging from sand and ballast— which includes earth, rubble and ash—to slack and cold coke. Where mechanical loading from a hopper or excavator may be contemplated, a cab shield is advisable, the small extra initial expense being decidedly preferable to that involved in rebuilding a driver's cab.

A point in connection with excavator loading is that occasionally the digger bucket is smacked against the body top rails, either accidentally or in order to shake out clogged material. This practice, although avoided by good digger operatives, is not exactly conducive to the long life of the truck, which reacts accordingly.

Excavated material often contains lumps of concrete and steel, and when regularly carrying such loads, a body constructed of heavier-gauge steel, but still of standard design, is advisable. In the same way, if large pieces of heavy solid matter are likely to be dropped into the truck, a reinforced floor is preferable, although chassis strength should also be considered in this instance.

The heavy-duty body is another type in wide use today. It is popularly known as a "dumper," but, in fact, in this country " dumper " is a term applied solely to forward-tipping bodies, with the driving position behind the body: all other types are "tippers." All

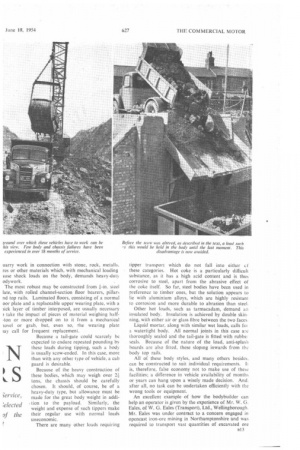

uarry work in connection with stone, rock, metallit, res or other materials which, with mechanical loading lose shock loads on the body, demands heavy-duty odywork.

The most robust may be constructed from 4-in. steel late, with roiled channel-section floor bearers, pillars nd top rails. Laminated floors, consisting of a normal oor plate and a replaceable upper wearing plate, with a lick layer of timber interposed, arc usually necessary ) take the impact of pieces of material weighing half-ton or more dropped on to it from a mechanical tovel or grab, but, even so, the wearing plate ray call for frequent replacement.

Because a tail-gate could scarcely be expected to endure repeated pounding by

1\1 these loads during tipping, such a body

is usually scow-ended. In this case, more is usually scow-ended. In this case, more than with any other type of vehicle, a cab guard is desirable.

Because of the heavy construction of these bodies, which may weigh over 2i tons. the chassis should be carefully chosen. It should, of course, be of a heavy-duly type, but allowance must be made for the great body weight in addition to the payload. Similarly, the weight and expense of such tippers make their regular use with normal loads uneconomic.

There are many other loads requiring tipper transport which do not fall into either ct these categories. Hot coke is a particularly difficult substance, as it has a high acid content and is thus corrosive to steel, apart from the abrasive effect of the coke itself. So far, steel bodies have been used in preference to limber ones, but the solution appears to lie with aluminium alloys, which are highly resistant to corrosion and more durable to abrasion than steel.

Other hot loads, such as tarmacadam, demand an insulated body. Insulation is achieved by double skinning, with either air or glass fibre between the two faces Liquid mortar, along with similar wet loads, calls fo: a watertight body. All normal joints in this case are thoroughly sealed and the tail-gate is fitted with rubbe. seals. Because of the nature of the load, anti-splash boards are also fitted, these sloping inwards from the body top rails.

All of these body styles, and many others besides, can be constructed to suit individual requirements.

is, therefore, false economy not to make use of these facilities; a difference in vehicle availability of months or years can hang upon a wisely made decision. And. after all, no task can be undertaken efficiently with the wrong tools or equipment.

An excellent example of how the bodybuilder can help an operator is given by the experience of Mr. W. G. Eales, of W. G. Eales (Transport), Ltd., Wellingborough. Mr. Eales was under contract to a concern engaged in opencast iron-ore mining in Northamptonshire and was required to transport vast quantities of excavated ore

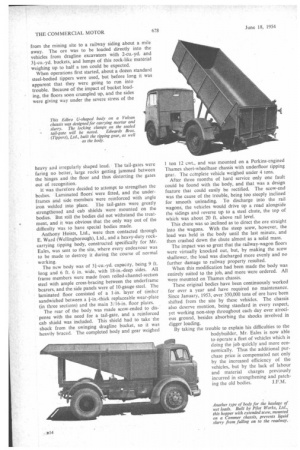

from the mining site to a railway siding about a mile away. The ore was to be loaded directly into the vehicles from dragline excavators with 2-cu.-yd. and 31-cu.-yd. buckets, and lumps of this rock-like material weighing up to half a ton could be expected.

When operations first started, about a dozen standard steel-bodied tippers were used, but before long it was apparent that they were going to run into trouble. Because of the impact of bucket loading, the floors soon crumpled up, and the sides were giving way under the severe stress of the heavy and irregularly shaped load. The tail-gates were faring no better, large rocks getting jammed between the hinges and the floor and thus distorting the gates out of recognition.

It was therefore decided to attempt to strengthen the bodies. Laminated floors' were fitted, and the underframes and side members were reinforced with angle iron welded into place. The tail-gates were greatly strengthened and cab shields were mounted on the bodies. But still the bodies did not withstand the treat .. ment, and it was obvious that the only way out of the difficulty was to have special bodies made.

Anthony Hoists, Ltd., were then contacted through E. Ward (Wellingborough), Ltd., and a heavy-duty rockcarrying tipping body, constructed specifically for Mr. Eales, was sent to the site, where every endeavour was to be made to destroy it during the course of normal working.

The new body was of 3I-cu.-yd. capacity, being 9 ft. long and 6 ft. 6 in. wide, with 18-in.-deep sides. All frame members were made from rolled-channel-section steel with ample cross-bracing between the underframe bearers, and the side panels were of 10-gauge steel. The laminated floor consisted of a 1-in, layer of timber sandwiched between a 1-in.-thick replaceable wear-plate (in three sections) and the main 3/16-in, floor plates.

The rear of the body was made scow-ended to dispense with the need for a tail-gate, and a reinforced cab shield was included. This shield had to take the shock from the swinging dragline bucket, so it was heavily braced. The completed body and gear weighed 1 ton 12 cwt., and was mounted on a Perkins-engined Thames short-wheelbase chassis with underfloor tipping gear. The cornplete vehicle weighed under 4 tons.

After three months of hard service only one fault could be found with the body, and that was a design feature that could easily be rectified. The scow-end was the cause of the trouble, being too steeply inclined for smooth unloading. To discharge into the rail wagons, the vehicles would drive up a road alongside the sidings and reverse up to a steel chute, the top of which was about 20 ft. above rail level.

This chute was so inclined as to direct the ore straight into the wagons. With the steep scow, however, the load was held in the body until the last minute, and then crashed down the chute almost as a solid mass.

The impact was so great that the railway-wagon floors were virtually knocked out, but, by making the scow shallower, the load was discharged more evenly and no further damage to railway property resulted.

When this modification had been made the body was entirely suited to the job, and more were ordered. All were mounted on Thames chassis.

These original bodies have been continuously worked for over a year and have required no maintenance. Since January, 1953, over 350,000 tons of ore have been shifted from the site by these vehicles. The chassis also deserve mention, being standard in every respect, yet working non-stop throughout each day over atrocious ground, besides absorbing the shocks involved in digger loading.

By taking the trouble to explain his difficulties to the bodybuilder, Mr. Eales is now able to operate a fleet of vehicles which is doing the job quickly and more economically. Thus the additional purchase price is compensated not only by the increased efficiency of the vehicles, but by the lack of labour and material charges previously incurred in strengthening and patch ing the old bodies. J.F.M. Thirteen regular drivers and attendants are employed some working 48 hours a week and some 44 on a rota which changes weekly. Although occasional journeys are made to places as far away as London and Leeds, the aggregate mileage is not great and the fleet and staff are adequate to cope with the work. Mr. Witcomb Smith was good enough to give me the breakdown of his costs and they are shown in Table Worcestershire presents quite a different problem and set-up. The administrative county is roughly rectangular in shape with the bulk of the population concentrated in the north-eastern industrial area which, in fact, forms part of the Birmingham conurbation. Almost in the middle of the county is the city of Worcester, which as a county borough is itself responsible for the provision of an ambulance service. The area of the county and city together is about 81 times that of Birmingham, but the population is not much more than one-third of that city.