GREATER LOA1 LESS FUEL

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

test along the same route, the two vehicles being almost identical except for slight gear ratio variations. When carrying similar loads, they proved to be equally matched for fuel consumption and general liveliness, and each result could virtually be relied on as a check for the other.

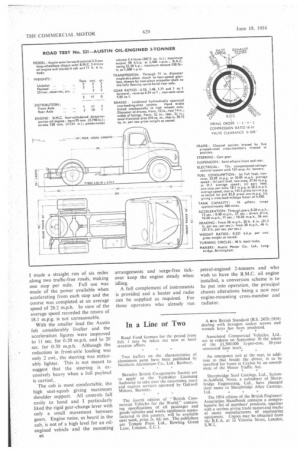

The B.M.C. direct-injection oil engine produces 58 b.h.p. at 2,400 r.p.m., with a maximum torque of 150 lb.-ft. at 1.500 r.p.m. It is a fourcylindered engine with a bore of 95 mm. and stroke of 120 mm., and has a cast-iron crankcase and cylinder block which carries wet liners.

The crankshaft and camshaft each have five bearings, a triplex chain driving the camshaft and Simms injection pump from the front of the crankshaft.

Cooling is unconventional in that only the cast-iron cylinder head is supplied with coolant from the centrifugal pump, the cylinder bores being cooled by thermo-syphon. The bores thus warm up quickly, helping B4 entering the AC mechanicallift pump. A Simms full-flow filter is included in the feed line between the lift and injection pumps.

The four-speed gearbox covers a wide ratio range, and is driven from the engine through a heavy. duty clutch with sprung centre plate. The engine and gearbox assembly has four-point mounting. Metala.stik two-tier-barrel rubbers being used at the front and two Metalastik "U "section units at the gearbox. These rear rubbers prevent fore-and-aft movement of the engine in addition to absorbing oscillation under maximum torque conditions. Although the engine cowling projects substantially into the cab, as it is a semi-forward-control vehicle, there is room to seat two passengers comfortably alongside the driver.

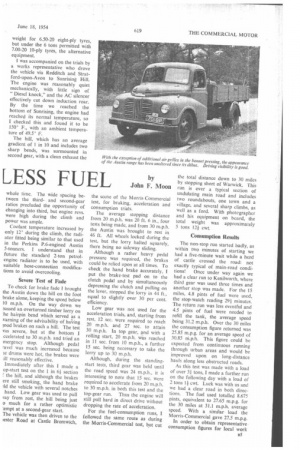

When I joined the lorry at the Longbridge works it was already loaded with 3 tons 1 cwt. of concrete blocks and sandbags, bringing the g.v.w. up to 5 tons 7i cwt. This was 2i cwt. above the permissible

whole time. The wide spacing between the thirdand second-gear ratios precluded the opportunity of changing into third, but engine revs. were high during the climb and power was ample.

Coolant temperature increased by only 12° during the climb, the radiator fitted being similar to that used in the Perkins P.6-engined Austin 5-tonners. I understand that in future the standard 2-ton petrolengine radiator is to be used, with suitable hose-connection modifications to avoid overcooling.

Severe Test of Fade

To check for brake fade I brought the Austin down the hill on the foot brake alone, keeping the speed below 10 m.p.h. On the way down we 3assed an overturned timber lorry on he hairpin bend which served as a yarning of the advisability of halTing ;ood brakes on such a hill. The test vas severe, but at the bottom I ccelerated to 30 m.p.h. and tried an mergency stop. Although pedal ravel was much increased because le drums were hot, the brakes were ill reasonably effective.

Immediately after this I made a op-start test on the 1 in 61section the hill, and although the brakes ere still smoking, the hand brake ;Id the vehicle with several notches hand. Low gear was used to pull vay from rest, the hill being just o much for a rather optimistic :empt at a second-gear start.

The vehicle was then driven to the tester Road at Castle Bromwich, the scene of the Morris-Commercial test, for braking, acceleration and consumption trials.

The average stopping distance from 20 m.p.h. was 20 ft. 6 in., four tests being made, and from 30 m.p.h. the Austin was brought to rest in 46 ft. All wheels locked during the test, but the lorry halted squarely, there being no sideway sliding.

Although a rather heavy pedal pressure was required, the brakes could be relied upon at all times. To check the hand brake accurately. I put the brake-test pad on to the clutch pedal and by simultaneously depressing the clutch and pulling on the lever, stopped the lorry in 44 ft., equal to slightly over 30 per cent. efficiency.

Low gear was not used for the acceleration trials, and, starting from rest, 12 sec. were required to reach 20 m.p.h. and 27 sec. to attain 30 m.p.h. In top gear, and with a rolling start, 20 m.p.h. was reached in 11 sec. from 10 m.p.h., a further 15 sec. being necessary to take the lorry up to 30 m.p.h.

Although, during the standingstart tests, third gear was held until the road speed was 24 m.p.h., it is interesting to note that 15 sec. were required to accelerate from 20 m.p.h. to 30 m.p.h. in both this test and the top-gear run. Thus the engine will still pull hard in direct drive without dropping the rate of acceleration.

For the fuel-consumption runs, I followed the same route as during the Morris-Commercial test, but cut

the total distance down to 30 miles by stopping short of Warwick. This run is over a typical section of undulating main road and includes two roundabouts, one town and a village, and several sharp climbs, as well as a ford. With photographer and his equipment on board, the total weight was approximately 5 tons 12i cwt.

consumption Results

The non-stop run started badly, as within two minutes of starting we had a five-minute wait while a herd of cattle crossed the road: not exactly typical of main-road conditions! Once under way again we had a clear run to Kenilworth, where third gear was used three times and another stop was made. For the 15 miles, 4.8 pints of fuel were used, the stop-watch reading 291 minutes. The return run was less eventful and 4.5 pints of fuel were needed to refill the tank, the average speed being 31.2 m.p.h. Over the 30 miles the consumption figure returned was 25.85 m.p.g. for an average speed of 30.85 nri.p.h. This figure could be expected from continuous running through urban areas and would be improved upon on long-distance hauls along less obstructed roads.

As this test was made with a load of over 31 tons, I made a further run on the following day with a load of 2 tons I cwt. Luck was with us and we had a clear road in both directions. The fuel used totalled 8.675 pints, equivalent to 27.65 m.p.g. for the 30 miles at 31.1 m.p.h. average speed. With a similar load the Morris-Commercial gave 27.5 tn.p.g.

In order to obtain representative consumption figures for local work I made a straight run of six miles along two traffic-free roads, making one stop per mile. Full use was made of the power available when accelerating from each stop and the course was completed at an average speed of 28.2 m.p.h. In view of the average speed recorded the return of 18.1 m.p.g. is not unreasonable.

With the smaller load the Austin felt considerably livelier and the acceleration figures were improved to 11 sec. for 0-20 m.p.h. and to 20 sec. for 0-30 m.p.h. Although the reduction in front-axle loading was only 2 cwt., the steering was noticeably lighter. This is not meant to suggest that the steering is excessively heavy when a full payload is carried..

The cab is most comfortable, the high seat-squab giving maximum shoulder support. All controls fall easily to hand and I particularly liked the rigid gear-change lever with only a small movement between gears. Engine noise, as heard in the cab, is not of a high level for an oilengined vehicle and the mounting 116 arrangements and surge-free tickover keep the engine steady when A full complement of instruments is provided and a heater and radio can be supplied as required. For those operators who already run petrol-engined 2-tonners and who wish to have the B.M.C. oil engine installed, a conversion scheme is to be put into operation, the principal chassis alterations being a new rear engine-mounting cross-member and radiator.