ODY FEATU ES of VANS and LOR RIBS M ATERIALS of

Page 96

Page 97

If you've noticed an error in this article please click here to report it so we can fix it.

a similar quality are usually employed in the construction of bodies for both vans and lorries as well as for private cars. Commercial vehicles have to withstand more pro

longed and harder usage than do motorcars, and as the weight of the vehicle decides the rate of taxation imposed it is impossible to build a body which is both strong and light in weight if inferior materials be employed. Weight is reduced by keeping the floor as close to the chassis as possible and, whenever the conditions allow, embodying a wheel-arch. Much has been learnt from busbody construction regarding the reduction of weight, principally in the use Of fewer and lighter longitudinals for the bottom frame, as well as in the adoption of pressings and other light forms of metal reinforcement.

It is also easier to make a lightweight body if it has flat sides and ends, for then there is the opportunity for cross-bracing, which is unrivalled as a method of achieving lightness.

Although steel panels are much in favour, because they are inexpensive and impart strength to the surrounding framework, they are heavy when compared with aluminium, plywood or composition board.

Fabric panels are now being used as a means for saving weight, and have the additional advantage that they give the vehicle a distinctive appearance. There is no reason why this material should not be more extensively employed, because it can be supported with a foundation of plywood, or the load may be protected by the casing boards only and may be reinforced above the waist-level by slats or battens.

Another reason why the fabric panel should be popular for van construction is that fixed and loose sheets are a common form of van top or tilt cover. The fabric may not be so strong as a waterproof sheet, but the former is available in a far wider range of colours and graining& Fabric may also be employed for the roofs of boxvans when no top load has to be carried. Furthermore, this material has the advantage that it reduces the cost of production, because much painting is avoided, whilst, should the fabric be damaged, repairs can be effected more quickly and more cheaply than with a metal or wood panel.

Although fabric has certain attractions, it is probable that the ideal commercial body is that which is constructed entirely of metal. With this form of construction the body can be made as light as, if not lighter than, that which is of wood, provided that aluminium and duralumin be freely utilized rather than steel. It is also fireproof and is less susceptible to climatic conditions.

The most commonly recurring feature of commercial bodywork is the cab, and, as one type of driver's cab may be mounted in conjunction with one of several varieties of loading compartment, the cab is the most suitable part upon which to make experiments, with the advantage that It is the lesser half of the complete body and, moreover, a self-contained unit.

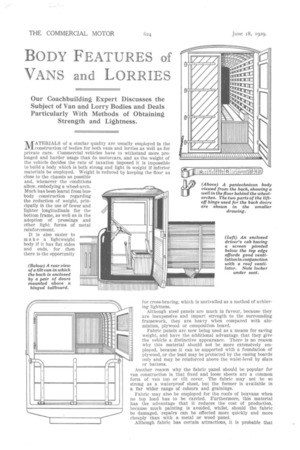

The enclosed cab is now a well-established feature of commercial bodywork. If the door be of extra width, no side window is reqUired at the end of the seat. Thus construction is simplified and the driver is able to get in and out of the cab more easily than with a narrower door. The larger entrance has a window of corresponding width, thus providing a side outlook for the driver which is superior to that available when the rear door-pillar is placed farther forward.

Opinions are divided as to whether the door should be hinged on the front or the rear pillar. The former method is preferred by some, because, should the door fly open accidentally it will tend to close again. On the other hand, a door hung on the rear pillar does not obstruct the gangway in front of the seat, and it should be possible to make the door self-closing by mounting it on spring hinges or upon a suitably designed spring checking device.

The ventilation of the cab is important, because its cubic capacity is comparatively small. Each door has a horizontally sliding or drop window, the former being preferred, as it is more convenient for signalling by hand. When the screen and door windows are open good ventilation is easily afforded, but provision must be made for adequate ventilation when all these inlets are closed by means of a louvre panel over the screen and an air extractor fitted at the back of the roof.

An interesting feature of modern van construction is the variation of the means employed for protecting the load at the rear. The typical method utilized is that of the hinged tailboard, which is used for both vans and lorries. The tailboard forms an end protection fdr the load and it holds the sides of the body together more securely than does a closed door. The tailboard can often be used as a temporary loading base.

Above the tailboard the enclosure may consist of one or a pair of waterproof curtains. These may be long and may be provided with side pieces, so that any load carried on the tailboard is properly covered. This design of rear curtain is often fitted to laundry vans.

The tailboard is designed to shut either between the body sides or against the ends of the sides, in which case the tailboard is extended the full width of the body. The " outside " board is the more common, but if a pair of doors be hung above the tailboard it is more convenient for it to shut inside and flush with the back of the body, because mounting the doors is facilitated.

Doors are used because they are more convenient to operate than a tailboard and are usually considered an essential feature of a high-class commercial vehicle, especially if it be of the lighter pattern. The doors are often hung on ordinary butt hinges, although the lift-off pattern is also frequently employed. The lift-off hinge consists of a hinge-iron having an eye at one end, the eye dropping over the pin or stud of a bolt which passes through the body pillar. As the hinge-line is vertical, the weight of the door keeps it in position and, having no retaining nut, the door may be lifted off when required so that it is out of the way when extensive loading and unloading are taking place, such as during a household removal.