A British Fleet of Tankers and Pipe-carriers for Persia

Page 56

Page 57

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

OPINIONS and QUERIES

Advantages of CopperAsbestos Gaskets. Trying Out a New Articulated Six-Wheeler Organizing the Maintenance and Repair of a Small Fleet. Equalizing Tyre Pressures

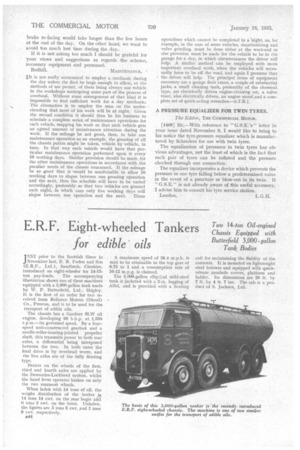

IN spite of the fact that Leyland Motors, Ltd., Leyland, Lanes, possesses an extensive overseas organization which enables the company to be kept advised of operating conditions in many parts of the world, it is sometimes considered wise to despatch a representative overseas to make a firsthand study of local conditions for any particular class of specialized work. Such a case occurred recently, when the .Aug1O-Persian Oil Co., Ltd., desired to place instructions for a fleet of tankers and pipe-carriers. The task of investigating these conditions was undertaken by the company's assistant general manager, Mr. Henry Spurrier, Junr., who spent a lengthy period in the Persian oilfields.

As a result of these investigations it was found that vehicles were required for use on a system of roads owned and built by the operating company itself in Persia, and whilst it was necessary for them to be of large load capacity they had to be constructed so that they could traverse without difficulty steep mountain roads abounding in hairpin bends. On one stretch of road no fewer than 45 such bends occur in a run of ten miles.

Leyland Motors, Ltd., secured the order for a fleet of nine vehicles, these comprising two 1,250-gallon fourwheeled tankers, a four-wheeled pipe'carrier, three 15-ton articulated tenwheeled goods vehicles, a 4,000-gallon ten-wheeled tanker and two 3,000gallon six-wheeled tankers.

Probably the most interesting of the fleet are the three dual-purpose articulated ten-wheeled 15-tonners. They consist of six-wheeled tractor chassis and four-Wheeled trailing bogies. The tractor has a Leyland 11-litre petrol engine of 150 b.h.p. which is governed 1342 to a maximum speed of 2,200 r.p.m. Left-hind steering is, of course, employed. In addition to the usual trailer-brake connection there is a hand-operated brake at the rear of the trailer, designed for operation when negotiating difficult gradients or for use when the unit is at rest on a steep incline.

These vehicles are designed for general transport work or for pipecarrying and will operate from the Anglo-Persian base at Abadan on the Persian Gulf, where material for inland schemes is landed. The tractors are, therefore, supplied with two trailing attachments, one having a fiat steelplatform body, 25 -ft. long, and the other a simple but heavy 32,-ft. framework for carrying pipes, which may measure as much as 40 ft. by 21. ft., to the main pipe lines. Ring bolts have been built in the sides of the trailer frame to take the chains which secure the unwieldy pipes in position.

As these goods vehicles will frequently he called upon to travel long distances over barren desert they have been equipped with a reserve 19-gallon water tank and a 55-gallon oil tank.

The tractor chassis of the ten. wheeled tanker is identical with those of the goods models, but the trailer differs considerably. On the goods models, in order to keep the platform body and the trailer frame ihorizontal, the trailer lc,logie is fitted with a subframe, lifting the body or the frame to the height of the turntable on the tractor. The trailer frame of the 4,000-gallon tanker, however, has been downswept immediately behind the turntable, the sub-frame on the trailer bogie being dispensed with in circler to provide as low a centre of gravity as possible. At the dropped portion of the

frame the side-members are strengthened by strong channel-section flitches welded to the side-members.

The 4,000-gallon tank is built in two compartments and is 22 ft. 9 ins. long, 7 it. 6 ins, wide and 5 ft. high. It is fitted with special transverse and longitudinal baffle plates to prevent surging.

The two 3,000-gallon tankers are based on a short-wheelbase six-wheeled chassis, both rear axles being driven. The 11-litre engine and an auxiliary gearbox are employed.

These three vehicles are to be used for feeding wayside filling stations and for transporting petrol from the depots to the Gulf. It is the company's intention to run them for 24 hours daily and there will be .a crew of three driverS to each machine. Special sleeping bunks have, therefore, been provided in thq cabs for the driver who is off duty.

One of the two 1,250-gallon fourwheeled tankers was shipped to Persia some time ago for service at the Bagdad Airport and was employed for refuelling the planes of competitors in the Melbourne Centenary Air Race from England to Australia. The lines of this machine follow closely the streamlined design which is gaining favour in England. The other fourwheeled tanker follows more orthodox lines. Both are mounted on Leyland Beaver six-cylinder petrol-engined chassis, suitably modified for overseas use and are fitted with Grass Mogul air springs.

The four-wheeled pipe-carrier is a similar Beaver. A narrow driver's cab, which has an additional door built into. the rear, permits the pipes to extend on each side of the cab from the allsteel hody, a pipe-carrying support being fitted a little forward of the radiator. THE MERITS OF COPPER-ASBESTOS GASKETS.

• The Editor, THE COMMERCIAL MOTOR.

[4465] Sir,—Of recent years much has been written regarding the difficulties, that have followed the development of engines of high efficiency, and many ways have been suggested for overcoming them.

Many of the methods suggested do not take into account the real cause of the trouble, and their consequent failure is not surprising. The engine of to-day tends steadily to obtain its efficiency by higher working pressures and consequent higher temperatures, therefore it is essential that the gasket should possess strength to withstand increased pressure and that the materials of which it is composed should favour the rapid elimination of heat.

To achieve these objects experience has shown us that we have nothing better at present than the well-tried combination of copper and asbestos. The metal, possessing as it does a high degree of conductivity, disperses heat rapidly and evenly over the surface of the head and block, and the combination possesses the neceSsary resilience to obtain a properly sealed joint. We find there is no other material or combination of materials that approaches this efficiency and that its intelligent use will overcome all difficulties.

It is probably true that all, or nearly all, manufacturers of high-efficiency engines are using copper and asbestos joints, and for this reason alone it would be well• for owners experiencing trouble to communicate with the makers of their engines or with a well-known gasket

manufacturer before experimenting. GASKETS. Slough.

TESTING THE MORRIS-COMMERCIAL WITH T.T.A. DRAGON SEMI-TRAILER.

The Editor, THE COMMERCIAL MOTOR.

[4466] Sir,—Reading in your issue dated January 4 the account of the test you made of a Morris-Commercial tractor and our Dragon semi-trailer, there are two points on which we would like to comment. The first is that we do not make a non-detachable semi-trailer to come under 3 tons unladen weight with the Morris-Commercial 3-ton tractor, and the reason is that it is against the interests of our own reputation, of the dealer who sells it, and, most of all, of the operator who uses it.

The Dragon is built not only to give years of troublefree service under all ordinary conditions, but with that very essential margin of strength to cope with the most arduous -conditions and to take care of excess loading which, although deplorable, is an everyday, occurrence that has to be recognized. Such a trailer cannot be constructed with a *eight limit of 24 cwt.

The second point is your statement that it is possible for two moderately powerful men to wind down the front supporting wheels." This greatly surprised us, as our detachable semi-trailers—and there are many hundreds in service—are essentially one-man vehicles, and drivers of every type and description find no. difficulty in winding down the front support without outside help.

Upon investigating the circumstances relating to the test vehicle, we find that this had inadvertently been fitted with a double-start thread instead of a single-start

type, and, as a consequence, twice the effort that is nor-mally required was necessary to wind down the support wheels. This operation is definitely only one man's work, and we would appreciate your drawing attention to this in. your next-issue.

T. M. PATTERSON, For TRUCK AND TRACTOR APPLIANCE CO., (MANCHESTER), LTD.

Manchester 17.

[With reference to the first point mentioned by Mr. Patterson we would point out that in the Morris-Commercial catalogue dealing with the tractor unit is the following comment:—" When used in conjunction with non-detachable semi-trailers of approved design it comes within the unladen-weight limit of 3 tons and qualifies for the annual tax of 435 . . ." The second point is explained in the letter. No mention of this alternative winding gear was made to us during the test—ED.]

MAINTAINING A SMALL MIXED FLEET.

The Editor, THE COMMERCIAL MOTOR.

[4467] Sir,—As a reader of The Commercial Motor for many years I have found your articles most interesting and helpful. As you are so intimately connected with the operation of vehicles I was wondering whether you could help me with my little problem.

I have to prepare a scheme for the maintenance and repair of a mixed fleet of 10 vehicles, comprising two Ford 30 cwt., two Leyland Cubs, the rest various 5-tormers, one being equipped with a Dorman oil engine. These vehicles are out all day and return at various times from 5 p.m. onward. The chief difficulty is the arrangement of the work so that the mechanic will not 'have too much to do at night and yet keep busy during the period when the vehicles are out on the road during the day.

It is realized, that jobs such as decarbonizing and i343

brake re-facing would take longer than the few hours at the end of the day.. On the other hand, we want to avoid too much lost time during the day., If it is not asking too much I should be grateful for your views and suggestions as regards the scheme, necessary equipment and personnel.

Redhill. MAINTENANCE. '

lit is not really economical to employ a mechanic during the day unless the fleet be large enough to allow, or the methods of use permit, of there being always one vehicle in the workshops undergoing some part of the process of overhaul. Without some arrangement of that kind it is impossible to find sufficient work for a day mechanic. The alternative is to employ the man on the understanding that most of his work will be at night. Given the second condition it should then be his business to schedule a complete series_ of maintenance operations for each vehicle, mapping his week so that each vehicle gets an agreed amount of maintenance attention during the week. If the mileage be not great, then, to take one maintenance operation as an example, the greasing of all the chassis points might be taken, vehicle by vehicle, in turn. In that way each vehicle would have that particular maintenance operation performed upon it every 10 working days. Similar provision should be made, for the other maintenance operations in accordance with the peculiar needs of the chassis concerned. If the mileage be so great that it would be unadvisable to allow 10 working days to elapse between one greasing operation and the next, then the schedule will have to be varied' accordingly, preferably so that two vehicles are greased each night, in which case only five working days will elapse between one operation and the next. Those

operations which cannot be completed in a 'night, as, for example, in the case of some vehicles, decarbonizing and valve grinding, must be done either at the week-end or else provision must be made for the vehicle to be in the garage for a day, in which circumstances the driver will help. A similar method can be employed with more important overhaul work, when the vehicles will necessarily have to be off the road, and again I presume that the driver will help. The principal items of equipment necessary are a garage floor crane, a couple of substantial jacks, a small cleaning tank, preferably of the chemical type, an: electrically driven engine-cleaning set, a valve truer, also electrically driven, an engine stand and a complete set of quick-acting wrenches.—S.T.R.1 A PRESSURE EQUALIZER FOR TWIN TYRES.

The Editor, THE COMMERCIAL MOTOR.

[4468] Sir,—With reference to " G.S.E.'s " letter in your issue dated November 9, I would like to bring to his notice the tyre-pressure equalizer which is manufactured by Schraders for use with twin tyres.

The equalization of pressures in twin tyres has obvious advantages, not the least of which is the fact that each pair of tyres can be inflated and the pressure checked through one connection.

The equalizer incorporates a device which prevents the pressure in one tyre falling below a predetermined value in the event of a puncture or blow-out in its twin. If " G.S.E." is not already aware of this useful accessory, I advise him to consult his tyre service station.

London. L . G. H.