An Ingenious New Coupling

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

for articulated vehicles

A System Invented by the Carrimore Company which Permits Squareended Semi-trailer Body to Extend to within 6 ins. of Cab when Units are in Line

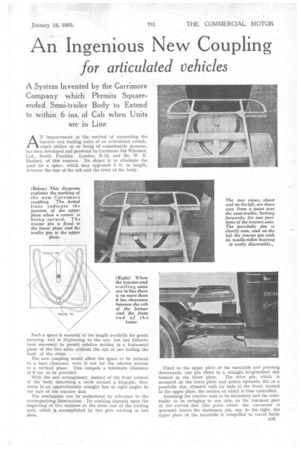

AN improvement in the method of connecting the tractive and trailing units of an articulated vehicle, which strikes us as being of considerable moment, has been developed and patented by Carrimore Si Wheelers, Ltd., North Finchley, London, N.12; and Mr. W. E. Herbert, of this concern.Its object is to eliminate the need for a space, which may approach 2 ft. in length, between the rear of the cab and the front of the body.

Such a space is wasteful of the length available for goods carrying, and is displeasing to the eye, but has hitherto been necessary to permit relative motion in a horizontal plane of the two units without the cab of one fouling the body of the other.

The new coupling would allow the space to be reduced. . to a bare clearance, were it not for the relative motion in a vertical plane. This compels a minimum clearance of 6 ins, to be provided.

With the new arrangement, instead of the front corners of the body describing a circle around a king-pin, they move in an approximately straight line at right angles to the axis of the tractive unit.

The mechanism can be "u.nderstood by reference to the accompanying illustrations. . Its working depends upon the imparting of two motions to the front end of the trailing unit, which .is. accomplished by two .pins working in two slots.

Fixed to the upper plate of the turntable and pointing downwards, one pin slides in a straight longitudinal slot formed in the lower plate. The other pin, which is mounted on the lower plate and points upwards, fits in a parabolic slot, situated with its ends to the front, formed in the tipper plate, the motion of which is thus controlled. Assuming the tractive unit to be stationary and the semitrailer to be swinging to one side, as the rearmost part of the curved slot (the point. where the. curvature is greatest) leaves the stationary pin, say, to the right, the upper plate of the turntable is compelled to travel back wards, with respect to the tractor, as it rotates. Centralization is meanWhile preserved by the forward pin, which moves along the straight slot, also towards the rear of the tractive unit, that is to say, away from the back of the cab. The slots are cut in fin. plates welded together, thus a Uinadeep bearing surface is afforded. Each pin carries a -needle-roller bearing, this being the approximate width of the slots. Provision for lubrication of these bearings is afforded by grease-nipples in the undersides of the pins.

We witnessed, this week, a demonstration of an articulated machine in which this new Carrimore coupling was incorporated, and were much impressed by its performance. The small clearance-between the front of the trailer frame and the back of the cab is clearly shown in one of the accompanying pictures, but the machine photographed was manceuvred in our presence until the tractor had turned through more than 90 degrees relative to the semi-trailer, the clearance increasing slightly during the operation.

In view of the 33-ft. legal limit for the overall length of articulated six-wheelers, the value of the additional forward overhang of the trailing unit that is thus permitted is easily appreciated, whilst a further advantage is the extra weight that • can be imposed on the driving wheels.

It might be thought that the shifting of weight away from the turning centre, when a corner is being rounded, might cause some slight danger of overturning. It can he seen, however, that this is not the case, when it is remembered that the extreme backward position of the semitrailer—that in which the side transference of weight is greatest—is the normal position of a semi-trailer in which a conventional king-pinatype of fixing is employed. .

With regard to the pressures created between the needleroller bearings and the walls of the slots, by the tractive force transmitted by them, these might he expected to be rather high through the wedging action that seems unavoidable, but doubtless they are designed to withstand any heavy loading to which they may be subjected.