THE UPKEEP OF THE AUSTIN TWELVE.

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

A Cause of Oil Leakage. The Four-wheel Brakes.

As the Austin Twelve chassis is used to a considerable extent -for highclass vans and ambulances some notes on its upkeep will' not be out of place. Occasionally an engine will be found persistently to become oily and dirty on the near side, and the cause of this is not always easy to discover.

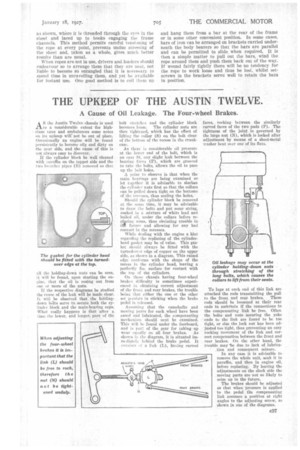

If the cylinder block be well cleaned with imeatfin on the tappet side and the two beesiliel pines (B) removed so that

all the holding-down nuts can be seen, it will be found, upon starting the engine, that the oil is oozing out from one or more of the nuts.

If the respective diagrams be studied ihe CRIM of the leak will be made clear. It will be observed that the holdingdown bats serve to secure both the cylinder block and the main-bearing caps. What really happens is that -after a time the lower, and longer, part of the

bolt stretches and the cylinder block becomes loose. The cylinder .nuts are then tightened, which has the effect of lifting the collar (S) on the bolt clear of the bottom of the recess in the crankcase.

As there is considerable oil pressure at the lower end of the bolt, which is an easy tit, any slight leek between the bearing faces al, which are grooved to take the bolts, allows the oil to pass up the bolt holes.

A point to observe is that when the main bearings are being examined or let together it is advisable to slacken the cylinder nuts first so that the collars can be pelted down tight on the bottoms of the recesses, thus sealing the holes.'

Should the cylinder block be removed at the same time, it may be advisable to draw the bolts and put some string, soaked in a mixture of white lead and boiled oil, under the collars before re/Aldine Same, thus obviating trouble in flit futhre and allowing for any bad contact ill the recesses.

While dealing with the engine a hint regarding the replacing of the cylinderbead gasket may be of value. This gasket should always be fitted with the turned-over edge of copper on the upper side, as shown in a diagram. This raised edge conforms with the shape of the recess in the cylinder head, leaving a perfectly flat surface for contact with the top of the cylinders.

On those chassis having four-wheel braku's difficulty is sometimes expericaved in obtaining correct adjustment of the front and rear brakes, the trouble beiug that either the one or the other set persists in sticking when the brake pedal is released.

Assuming that the camshafts and moving parts for each wheel have been eased and lubricated, the c3mpensating mbehanisia should next be examined. This will be found under the footboard, and is part of the gear for taking up wear equally on all four brakes. As shown in the diagram, it is situated imnn diately behind the brake pedal. It fee.sists ef a link (L), having curved

faces, rocking between the similarly curved faces of the two pads (P). The tightness of the joint is governed by the large nut (N), which is locked after adjustment by means of a sheet-metal washer bent oser one of its flats.

To lugs at each end of this link are attached the rods transmitting the pull to the front and rear brakes. These rods should be loosened at their rear ends to ascertain if the connections to the compensating link be free. Often the bolts and nuts securing the yoke ends to the link are found to be too tight, or else the lock nut has been adjusted too tight, thus preventing an easy rocking movement of the link and correct compensation between the front and rear brakes. On the other hand, the trouble may 'be due to lack of lubrica

tion and consequent seizure.

In any ease it is advisable to remove the whole unit, soak it in paraffin, and then in engine oil, before replacing. By leaving the adjustments on the slack side the moving parts are not so likely to seize up in the future.

The brakes should be adjusted so that when pressure is applied to the pedal the compensating link assumes a position at right angles to the adjusting screw, as shown in one of the diagrams.