Battery bus research

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

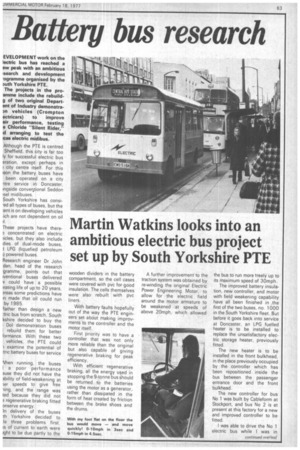

Martin Watkins looks into an ambitious electric bus project set up by South Yorkshire PTE

EVELOPMENT work on the lectric bus has reached a ew peak with an ambitious search and development .ogramme organised by the outh Yorkshire PTE.

The projects in the proamme include the rebuildg of two original Depart-. ent of Industry demon straan vehicles (Crompton ectricars) to improve eir performance, testing e Chloride "Silent Rider," id arranging to test the was electric midibus.

Although the PTE is centred Sheffield, this city is far too ly for successful electric bus eration, except perhaps in city centre itself. For this ison the battery buses have been operated on a city ntre service in Doncaster, ingside conventional Seddon sel rnidibuses.

South Yorkshire has consi-ed all types of buses, but the :ent is on developing vehicles iich are not dependent on oil These projects have there concentrated on electric )icles, but they also include dies of dual-mode buses, 1 LPG (liquefied petroleum t) powered buses.

Research engineer Dr John dan, head of the research Igramme, points out that iventional buses delivered v could have a possible ;rating life of up to 20 years, areas some predictions have Ti made that oil could run by 1985.

Rather than design a new ;tric bus from scratch, South kshire decided to buy the Dot demonstration buses I rebuild them for better formance. With these two vehicles, the PTE could I examine the potential of :tric battery buses for service rVhen running, the buses I a poor performance ause they did not have the ability of field-weakening at ler speeds to give free ling, and the range was ted because they did not a regenerative braking fitted onserve energy.

ln delivery of the buses th Yorkshire decided to .le three problems first. cs of current to earth were ight to be due partly to the wooden dividers in the battery compartment, so the cell cases were covered with pvc for good insulation. The cells themselves were also rebuilt with pvc liners.

With battery faults hopefully out of the way the PTE engineers set about making improvments to the controller and the motor itself.

First priority was to have a controller that was not only more reliable than the original but also capable of giving regenerative braking for peak efficiency.

With efficient regenerative braking, all the energy used in stopping the 9-tonne bus should be returned to the batteries using the motor as a generator, rather than dissipated in the form of heat created by friction between the brake shoes and the drums. A further improvement to the traction system was obtained by re-winding the original Electric Power Engineering Motor, to allow for the electric field around the motor armature to be weakened at speeds of above 20mph, which allowed

the bus to run more treely up to Its maximum speed of 30mph.

The improved battery insulation, new controller, and motor with field weakening capability have all been finished in the first of the two buses, no. 1000 in the South Yorkshire fleet. But before it goes back into service at Doncaster, an LPG fuelled heater is to be installed to replace the unsatisfactory electric storage heater, previously fitted.

The new heater is to be installed in the front bulkhead, in the place previously occupied by the controller which has been repositioned inside the bus between the passenger entrance door and the front bulkhead.

The new controller for bus No 1 was built by Cableforrn at Stockport, and bus No 2 is at present at this factory for a new and improved controller to be fitted_ I was able to drive the No 1 electric bus while I was in Sheffield, and even engage in part of the development programme by taking the bus up the notorious East Bank hill for the first time.

I was very surprised at the effectiveness of the regenerative braking, which seemed far better than the other two battery electrics I have driven, the Lucas midibus and the Leyland National battery trailer bus that has Bosch electrics.

I think the braking power could easily catch out most drivers, as it varies greatly with the vehicle road speed and needs a very sensitive foot movement to bring the bus smoothly to a stop especially when it is travelling at speed.

Acceleration was very sprightly up to 20mph, this speed being reached in about 13.5 seconds: 1 Omph was reached in 3 seconds and 15mph in 4.5 seconds.

The passenger load in battery buses does not make the slightest difference, as the unladen weight is already so high_

I hardly used the service brakes at all, except to bring the bus to a dead stop, and I don't think any other driver would be called upon to use them either.

The regenerative braking stage takes up the first couple of inches of brake travel and is so effective that several times I unwittingly threw the South Yorkshire engineers in the bus towards the front.

When the second bus has been fitted with its new controller, South Yorkshire is hopeful that regeneration control will be milder.

The regeneration overun torque is something that the Leyland FG back axle in the bus was not originally designed to take, and this unit produced some grinding noises from time to time.

Manual steering was very heavy with the total vehicle weight around the 9-tonne mark, and South Yorkshire is considering fitting power steerring to it to ease this load.

The last thing one expects to find in an electric vehicle is noise, but my trial run in the bus took place before sound insulation material had been fitted around the controller unit. Starting from rest the controller produced a loud buzzing noise fro the first few seconds, and also when using the regenerative braking the unit produced some spectacular arcing from the circuit breakers These breakers are designed to last for at least 500 fullpower changes, but changing them will be a simple job. The strange noises will, hopefully, be banished as South Yorkshirhas designed an insulated box to cover the controller which it expects to result in completely silent operation_ The Doncaster city centre service that the buses will operate on is fairly flat with a maximum gradient of 1 in 30 over a distance of 50 metres (54 yards) — nothing like as severe as the hills the bus proved it could tackle during my test run in Sheffield.

The distance round the Doncaster circuit is 2.24 miles and has an average of 10 to 12 stops per mile (including traffic stops). The bus is scheduled to cover this in 15 minutes, with five minutes waiting time in the bus station between circuits.

The dead mileage between. the Doncaster charging point and the start of the run at the bus station is 3km (1.866 miles).

It is envisaged that the electric buses will spend five hours a day in service, on a schedule working during both the morning and evening p( periods. Thus the maxim daily distance the bus will called on to cover in service be 70km (43 miles), with charge in between morning evening service.

Although the PTE has tried any long runs in the since it was rebuilt, it estimi that it is capable of a maxirr range of 120km (74 miles).

For the low mileac required in operation, So Yorkshire has been prepare( sacrifice range to give gi acceleration, and now feelsl further improvements to aq leration could result in j senger discomfort.

The estimated life of batteries — of conventi( tubular plate construction around 1,600 cycles of cha and discharge. This is probz much longer than the flat p batteries used in other elec bus designs.

It seems that using con' tional /acid batteries modified buses has been ta nearly to the limits of de: work by the South Yorks PTE research and developrr team. No doubt if they cc design a new bus from scra rather than modify exis buses based on outdated truck chassis, they could duce a vehicle with still b performance, by using v they have already learnt.

The real development spect for all electric vehicles in lighter and more advar batteries like sodium /sulp The high temperatures at w these batteries operate nE care, especially in designir bus, as safety is a pi consideration.

Despite this, Dr Jordan the other engineers are loo forward to the challengE trying out purpose-1 sodium /sulphur powered b one day, when these batt( have been developed furthE