A slight case of head gasket hell

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

TRAVELLING down through Southam en route from Coventry to Oxford one day, I thought as we went round the narrow S-bend at the southern end of the village, I could hear faint signs of a head gasket blow.

I went on for a few more miles, letting the road speed fall right off and then accelerating in top gear to put as much load as possible on the engine and, right enough, there was a blow there somewhere.

There are two sorts of head gasket failure, one that allows water to seep through into the oil, and the other which permits cylinder gas to escape between the head and block.

The • first of these, while serious and obviously having to be cured, is not an immediate stopper, and providing you keep an eye on the water level and the degree to which your oil is contaminated,.. it is quite acceptable to soldier on to the end of the week and so not lose any productive time in effecting the repair.

A gas blow, however, is a different matter entirely, for it can result in very expensive damage even if allowed to go on for only the shortest period.

A gas blow is the result of a failure in the seal between head and Hock, and each time that paricular cylinder fires, a sear ing ' flame under extreme pressure shoots through the minute gap,. blowing and burning away the metal of the block face and the cylinder head.

One hour s running on full throttle at 2000rpm means that 60,000 of these flames have had a nibble at the faces of your joint, and even after that short period, already you could be in for a dismal future of head-gasket hell.

Once a gas cut is formed you have no chance whatever of achieving satisfactory head gasket life until the two faces are reground.

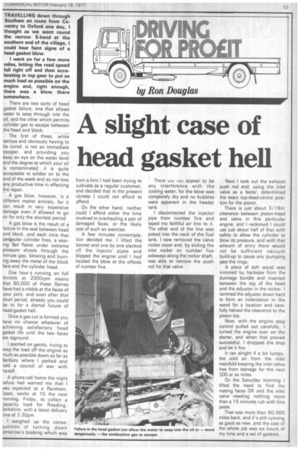

I pootled on gently, trying to A phone-call home the night )efore had warned me that I Nas expected at a Rainham, Essex, works at 10 the next norning, Friday, to collect a .:apacity load for Reading, 3erkshire, with a latest delivery ime of 3.30pm. I weighed up the conseluences of turning down °morrow's booking which was from a firm I had been trying to cultivate as a regular customer, and decided that in the present climate I could not afford to offend. On the other hand, neither could I afford either the time involved in overhauling a pair of damaged faces, or the likely cost of such an exercise. A few minutes contemplation decided me. I lifted the bonnet and one by one slacked off the injector pipes and blipped the engine until I had located the blow at the offside of number five. There ow Hut appear to be any interference with the cooling water, for the blow was completely dry and no bubbles were apparent in the header tank. I disconnected the injector pipe from number five and taped my faithful air line to it. The other end of the line was poked into the neck of the fuel tank. I now removed the valve rocker cover and, by sliding the inlet rocker on number five sideways along the rocker shaft, was able to remove the push rod for that valve. Next I took out the exhaust push rod and, using the inlet valve as a feeler, determined. the exact top-dead-centre position for the piston. There is just about 3/16in clearance between piston-head and valve in this particular engine, and I reckoned I could use just about half of that with safety to allow the cylinder to blow its pressure, and with that amount of entry there would not be sufficient vacuum build-up to cause any pumping past the rings. A piece of soft wood was trimmed by hacksaw from the dunnage bundle and inserted between the top of the head and the adjuster in the rocker. I rammed the adjuster down hard to form an indentation in the wood for a location and carefully halved the clearance to the piston top. Now, with the engine stop control pulled out carefully, I turned the engine over on the starter, and when that proved successful, I dropped the stop and let it fire. It ran alright if a bit lumpy, the cold air from the inlet manifold keeping the inlet valve free from damage for the next 200 or so miles. On the Saturday morning lifted the head to find my mating faces OK and the inlet valve needing nothing more than a 15 minutes rub with fine paste. That was more than 80,000 miles back, and it's still running as good as new, and the cost of the whole job was six hours of my time and a set of gaskets.