MODERN SUSPENSION SYSTE S IS A CHANGE JUSTIFIED?

Page 42

Page 43

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

THERE is hardly a part of a motor-vehicle, chassis that is subjected to so many variable stresses or has to perform such onerous duties as the road springs, and it says much for modern design and the quality of the materials used that so little trouble is experienced from this quarter.

Designers are frequently criticized for adhering to the leaf spring, but it is thought that the critics cannot be fully conversant with the functions which the springs perform beyond that of serving as a flexible load-carrying beam.

Of the many factors with which the designer has to contend, there are static load, the effects of braking and load transference as the direct result, the cruising speed of the vehicle, the provision of reasonably light and responsive steering and the important factor of safety.

Despite the fact that many attempts have been made to depart from the use of the conventional leaf spring, there are to-day few exceptions to its adoption, and these are to be found mainly on vehicles built for specific types of service.

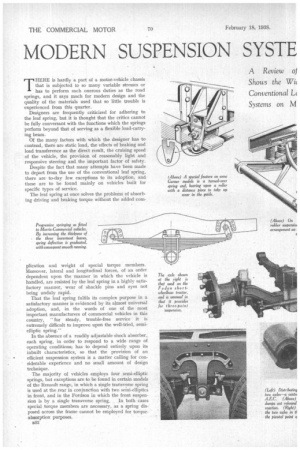

The leaf spring at once solves the problems of absorbing driving and braking torque without the added corn

plication and weight of special torque members. Moreover, lateral and longitudinal forces, of an order dependent upon the -manner in which the vehicle is handled, are resisted by the leaf spring in a highly satisfactory manner, wear of shackle pins and eyes not being unduly rapid.

That the leaf spring fulfils its complex purpose in a satisfactory manner is evidenced by its almost universal adoption, and, in the words of one of the most important manufacturers of commercial vehicles in this country, "for steady, trouble-free service it is extremely difficult to improve upon the well-tried, semi-. elliptic spring."

In the absence of a readily adjustable shock absorber, each spring, in order to respond to a wide range of operating conditions, has to depend entirely upon its inbuilt characteristics, so that the provision of an • efficient suspension system is a matter calling for considerable experience and no small amount of design technique.

The majority of vehicles employs four semi-elliptic springs, but exceptions are to be found in certain models of the Renault range, in which a single transverse spring is used at the rear in conjunction with two serni-elliptics in front, and in the Fordson in which the front suspen sion is by a single transverse spring. In both cases special torque members are necessary, as a spring disposed across the frame cannot be employed for torqueabsorption purposes. So wide may be the variation in the loads with which the springs have to contend, that means arc usually provided to impart a progressive action so that, under full load conditions, the spring assembly is stiffened up and over-deflection prevented.

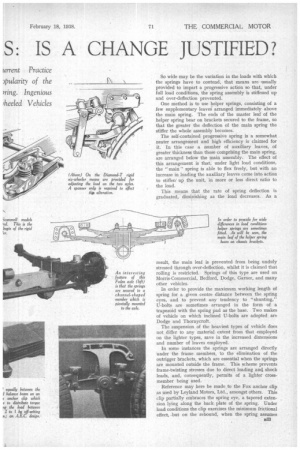

One method is to use helper springs, consisting of a few supplementary leaves arranged immediately above the main spring. The ends of the master leaf of the helper spring bear on brackets secured to the frame, so that the greater the deflection of the main spring the stiffer the whole assembly becomes.

The self-contained progressive spring is a somewhat neater arrangement and high efficiency is claimed for it. In this case a number of auxiliary leaves, of greater thickness than those comprising the main spring, are arranged below the main assembly. The effect of this arrangement is that, under light load conditions, the " main " spring is able to flex freely, but with an increase in loading the auxiliary leaves come into action to stiffen up the unit, in more or less direct ratio to the load.

This means that the rate of spring deflection is graduated, diminishing as the load decreases. As a result, the main leaf is prevented from being unduly stressed through over-deflection, whilst it is claimed that rolling is restricted. Springs of this type are used on Morris-Commercial, Bedford, Dodge, Garner, and many other vehicles.

In order to provide the maximum working length of spring for a given centre distance between the spring eyes, and to prevent any tendency to "shunting," U-bolts are sometimes arranged in the form of a trapezoid with the spring pad as the base. Two makes of vehicle on which inclined U-bolts are adopted are Dodge and Thornycroft.

The suspension of the heaviest types of vehicle does not differ to any material extent from that employed on the lighter types, save in the increased dimensions and number of leaves employed.

In some instances the springs are arranged directly under the frame members, to the elimination of the outrigger brackets, which are essential when the springs are mounted outside the frame. This scheme prevents frame-twisting stresses due to direct loading and, shock loads, and, consequently, permits of a lighter crossmember being used.

Reference may here be made to the Fox anchor clip as used by Leyland Motors, Ltd., amongst others. This clip partially embraces the spring eye, a tapered extension lying along the back plate of the spring. Under load conditions the clip exercises the minimum frictional effect, but on the rebound, when the spring assumes increased positive curvature, the clip automatically tightens its grip to introduce interplate friction on the longest leaves of the spring.

Another important function of this clip is that it serves to distribute torque reaction through as many of the longest leaves of the spring as are embraced by the clip shackle, a point determined in design.

Three-point suspension systems are unusual in the heavier types of vehicle, hence that employed on the Foden shortwheelbase tractor is interesting. In this design the front springs are secured to a channel-shaped member which fits over the axle, to the centre of which it is pivotally mounted.

Although the semi-elliptic spring is retained in the majority of rigid six-wheelers, its actual application varies according to the design of the vehicle and the specific operating conditions for which it is built.

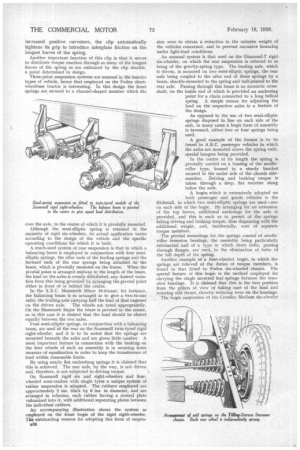

A much-used system of rear suspension is that in which a balancing beam is employed in conjunction with four semielliptic springs, the after ends of the leading springs and the forward ends of the rear springs being attached to the beam, which is pivotally mounted on the frame. When the pivotal point is arranged midway in the length of the beam, the load on the axles is evenly distributed, any desired variation from this being governed by arranging the pivotal point either in front of or behind the centre.

In the A.E.C. Mammoth Minor 10-tonner, for instance, the balancing beam is so arranged as to give a two-to-one ratio, the trailing axle carrying half the load of that imposed on the driven axle. The wheels are tyred appropriately. On the Mammoth Major the beam is pivoted in the centre, as in this case it is desired that the load should be shared equally between the two axles.

Four semi-elliptic springs, in conjunction with a balancing beam, are used at the rear on the Seamrnell twin-tyred rigid eight-wheeler, and it is to be noted that the springs are mounted beneath the axles and are given little camber. A most important feature in connection with the braking on the four wheels of such an assembly is in securing some measure of equalization in order to keep the transference of load withiht reasonable limits.

By using nearly fiat underslung springs it is claimed that this is achieved. The rear axle, by the way. is not driven and, therefore, is not subjected to driving torque.

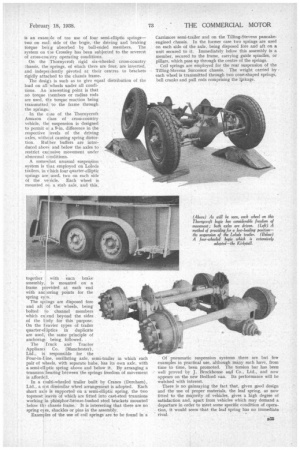

On Scammell rigid six and eight-wheelers and fourwheeled semi-trailers with single tyres a unique system of rubber suspension is adopted. The rubbers employed are approximately 2 ins, thick by 6 ins, in diameter, and are arranged in columns, each rubber having a central plate vulcanized into it, with additional separating plates between the individual rubbers.

An accompanying illustration shows the system as employed on the front bogie of the rigid eight-wheeler. The outstanding reasons for adopting this form of suspen

e34 sion were to obtain a reduction in the unladen weight of the vehicles concerned, and to prevent excessive bouncing under light-load conditions.

An unusual system is that used on the Diamond-T rigid six-wheeler, on which the rear suspension is referred to as being of the gravity-spring type. The leading axle, which is driven, is mounted on two semi-elliptic springs, the rear axle being coupled to the after end of these springs by a beam, shackle-mounted to the spring and ball-jointed to the rear axle. Passing through this beam is an eccentric crossshaft, on the inside end of which is provided an anchoring point for a chain connected to a long helical spring. A simple means for adjusting the load on the respective axles is a feature of the design.

As opposed to the use of two semi-elliptic springs disposed in line on each side of the axle, in many cases a bogie form of assembly is favoured, either two or four springs being used.

A good example of the former is to be found in A.E.C. passenger vehicles in which the axles are mounted above the spring ends, special hangers being provided.

In the centre of its length the spring is pivotally carried on a bearing of the needleroller type, housed in a sturdy bracket secured to the under side of the chassis sidemember. Driving and braking torque is taken through a deep, flat member slung below the axle.

A bogie which is extensively adopted On both passenger and goods vehicles is the Kirkstall, in which two semi-elliptic springs are used—one on each side of the bogie. By arranging for an extension of the top leaves, additional anchorage for the axle is provided, and this is such as to permit of the springs taking driving and braking torque, thus dispensing with the additional weight, and, incidentally, cost of separate torque members.

The pivotal mountings for the springs consist of needleroller trunnion bearings, the assembly being particularly substantial and of a type in which short bolts, passing through flanges, are used, to the elimination of bolts of the full depth of the spring.

Another example of a four-wheeled bogie, in which the springs are relieved of the duties of torque members, is found in that fitted to Foden six-wheeled chassis. The special feature of this bogie is the method employed for carrying the single inverted leaf springs between the trunnion bearings. It is claimed that this is the best position from the ptiints of view of taking care of the load and resisting side thrust, thereby reducing wear on the bearings.

The bogie suspension of the Crossley Medium six-wheeler is an example of roe use of four semi-elliptic springs— two on eacl, side of the bogie, the driving and braking torque beir g absorbed by ball-ended members. The system on tie Crossley has been subjected to the severest of cross-coo: ltry operating conditions.

On the Thornycroft rigid six-wheeled cross-country zbassis, the springs, of which there are four, are inverted, and indepei dently pivoted at their centres to brackets rigidly attached to the chassis frame.

The desigi is such as to give equal distribution of the load on all wheels under all conditions. An nteresting point is that no torque members or radius rods are used, tie torque reaction being transmitted to the frame through the springs.

In the c se of the Thornycroft Amazon c lass of cross-country vehicle, the suspension is designed to permit o: a 9-in, difference in the respective levels of the driving axles, with° at causing spring distor

tion, Rut: her buffers are introduced abovi and below the axles to restrict excfssive movement under abnormal conditions.

A somew hat unusual suspension system is that employed on Lolode trailers, in v hich four quarter-elliptic springs are used, two on each side of the ve iicle. Each wheel is mounted on a stub axle, and this, together with 'cacti brake assembly, is mounted on a

frame piovided at each end with anc toring points for the spring ey S.

The spi ings are disposed fore and aft of the wheels, being bolted lo channel members which ex end beyond the sides of the t ody for this purpose.

On the Feavier types of trailer quarter-el .iptics in duplicate are used, the same principle of anchorap being. followed.

The truck and Tractor Applianc■ Co. (Manchester), Ltd., is responsible for the Four-in-Line, oscillating axle, semi-trailer in which each pair of w heels, with separate hubs, has its own axle, with a semi-elliptic spring above and below it. By arranging a trunnion bearing between the springs freedom of movement is afforded.

In a r lulti-wheeled trailer built by Cranes (Dereham), Ltd., a ri A dissimilar wheel arrangement is adopted. Each short ax] e is supported on a semi-elliptic spring, the two topmost leaves of which are fitted into cast-steel trunnions working in phosphor-bronze-bushed steel brackets mounted below th chassis frame. It is interesting that there are no spring e5 es, shackles or pins in the assembly.

Examples of the use of coil springs are to be found in a

Carrimore semi-trailer and on the Tilling-Stevens pancakeengined chassis, In the former case two springs are used on each side of the axle, being disposed fore and aft on a unit secured to it. Immediately below this assembly is a member, secured to the frame, carrying guide spindles, or pillars, which pass up through the centre of the springs. Coil springs are employed for the rear suspension of the Tilling-Stevens Successor chassis. The weight carried by each wheel is transmitted through two cone-shaped springs, bell cranks and pull rods comprising the linkage.

Of pneumatic suspension systems there are but few examples in practical use, although many such have, from time to time, been promoted. The torsion bar has been • well proved by J. Brockhouse and Co., Ltd., and now appears on the new Bedford van. Its performance will be watched with interest.

There is no gainsaying the fact that, given good design and the use of proper materials, the leaf spring, as now fitted to the majority of vehicles, gives a high degree of satisfaction and, apart from vehicles which may demand a departure in order to meet some specific condition of operation, it would seem that the leaf spring has no immediate rival: