A TOTALLY NEW IDEA IN LOCK-NUTS.

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

A Method of Locking by Contraction of the Nut on to the Bolt.

THE factors which go towards maknig -a really successful lock-nut are more numeruns than one would, on first consideration of the. subject, suppose. Firstof all it must be 'as cheap to manufacture as the castellated nut, which, with its split-pin, has held the field very well against all-corners. Next, it must be as easy as the castellated nut to apply and secure. Then it. must be absolutely reliable, and last, but not least, its effectiveness should not be impaired in any wayby repeated removal and reapplica.tion.' There are many different lock-nuts on the market, and their weak spot, when they prove reliable on first use— when 'qiiite new—is in connection with the lastenamed consideration, for it often happens that under the initial tightening, the locking-faces are slightly, distorted, and at the second or third time of use they are found to be no longer fully reliable.

That the castellated nut, with its split-pin, is not above reproach is capable of being demonstrated any day at a hundred traffic stopping-places in London. These stopping-places could be detected merely by the nuts, bolts, splitpins and other strange bits of machinery found embedded in the wood .paving. They are the places where inertia plays its part in the dislodging of a part from its resting-place on the engine under screen or on some part of the chassis. Castellated nuts and split-pins could he dug up in the course of a day's expedition, sufficient to furnish a complete chassis. The castellated nut, again, is not ideal, for it is fatten found that a sixth of a turn necessary to cause the castellatiens to coincide with the hole in the bolt or stud is just too little or too much. Then split-pins are generally spoiled on extraction, and, whilst the cost of a new one is little, it. often happens that a pin of the size required is not. in stock. The fact that the castellated nut is not self-contained causes a loss of time when securing and when removing it, whilst the need for the hole for the split-pin and for deciding where it shall be drilled involves further less of time, and when fine Work is being handled often puts the castellated nut out of court.

We have for some weeks now been carefully studying a. new lock-nut, de. signed by Mr. H. T. Hutton, of Erin Lodge, Donaghadee, Co. Down, Ireland, who was the inventor of the WoodMilne foot pump, which opened an entirely new era in the inflation of pneumatic-tyres. A considerable amount of time has been spent and research work undertaken in connection with the invention, and everything so far done has gone to show that Mr: Hutton has devised a system of mat locking whish fulfils all the requirements we have laid down. Looking at the section of the nut, one would think it could not. be an easy or a cheap nut to make ; but, actually, it is as we shall show. Its' reliability has been demonstrated under conditions on power plant and road. vehicles where other locking methods had failed, and no instance of failure of the nut has yet occurred. Test nuts

have been applied, screwed tight, loosened and removed, the cycle of operation having been repeated 50 or snore times, and the nut has proved as efficient throughout as when new. It is easier to apply and secure and to remeve than the castellated nut and pin, and it is free from the obvious defects of those devices.

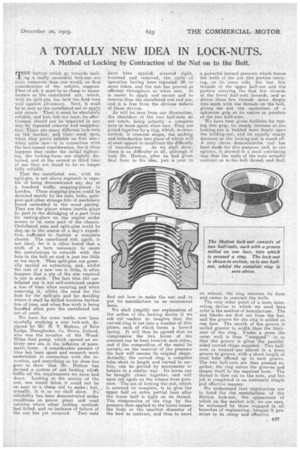

AS will be seen from our illustration, the -shoulders of the two half-nuts do not touch, being actually a complete turn or more apart when new. They are joined together by a ring, which, in crosssection, is crescent shape, the making and introduction into place of which will at, once appear to constitute the difficulty of manufacture. As we shall show, there is no difficulty at all, although it took Mr. Hutton, after he had given final form to his idea, just a year to

find out how to make the nut and to put its manufacture on an economical basis.

We shall simplify our explanation of the action of the locking device if we ask our readers to imagine that the . curved ring is cut into a number of thin plates, each of which forms a bowed spring. It will then be agreed that. on compression the two horns of the crescent can be bent towards each other, and if the composition of the metal be correct, on the removal of the pressure the bow will resume its original shape. Actually; the curved ring, a complete tube short in length and curved in section, can be • proved by micrometer to behave in a similar way. Its horns can be brought closer together, and will open out again on the release from pressure. The act of locking the nut, which / is screwed on complete, is to give the upper half an extra partial turn after the lower half is tight on its thread. The compression of the ring by the pressure thus applied to the horns causes the body or the smallest diameter of the bow to contract, and thus to exert

a powerful inward pressure which forces the walls of the nut (the portion carrying, on its inner side, the last, few threads of the -upper half-nut and the portion carrying the first few threads of the lower half-nut) inwards, and so drives those few threads more deeply into mesh with the threads on the bolt, giving -the nut the equivalent of a sphincter grip at its centre or junction of the two half-nuts.

'We have been given facilities for testing this grip, its steady increase as the locking-nut is bedded more firmly upon the holding-nut, and its equally steady decrease as the locking-nut is eased off. A very clever demonstration tool has been made for this -purpose, arid, in our opinion, it. showed in a most convincing way that the walls of the nuts actually contract on to the bolt thread, and that; on release, the ring recovers it form and ceases to contract the walls.

The only other point of a most interesting device to which we need here refer is the method of manufacture. The nut blanks are first cut, from the bar, and the groove for the ring is milled on one face. The mouth of the groove is milled greater in width than the thickness of the ring. Under a press the outer wall is then "snapped" in so that the groove is given the parallelsided curved shape required. Two halfnuts so treatedtare placed in a press groove to groove, with a, short length of steel tube offered up to each groove. The two half-nuts are then pressed together, the ring enters the grooves and shapes itself.to the required form. The thread is then cut on the nuts, and the job is completed in an extremely simple and effective manner.

We understand that negotiations are in hand for the manufacture of the Hutton lock-nut, the. appearance of which on the market will, we are sure, be welcomed by those engaged in all branches of engineering, because it promises to be cheap and effective.