Vulcan Enters 7-ton Range

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

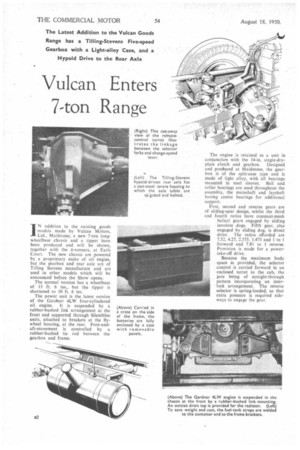

1 N addition to the existing goods models made by Vulcan Motors. Ltd.. Maidstone, a new 7-ton longwheelbase chassis and a tipper have been produced and will be shown, together with the 6-tonners, at Earls Court. The new chassis are powered by a proprietary make of oil engine, but the gearbox and rear axle are of Tilling Stevens manufacture and are used in other models which will be announced before the Show opens.

The normal version has a wheelbase of 13 ft. 6 ins., but the tipper is shortened to 10 ft. 6 ins.

The power unit is the latest version of the Gardner 4LW four-cylindered oil engine. It is suspended by a rubber-bushed link arrangement at the front and supported through Silentbloc units, attached to brackets at the flywheel housing, at the rear. Fore-andaft-movement is controlled by a rubber-bushed tie rod between the gearbox and frame. The engine is retained as a unit in conjunction with the 14-in, single-dry plate clutch and gearbox. Designed and produced at Maidstone, the gearbox is of the split-case type and is made of light alloy, with all bearings mounted in steel sleeves. Ball and roller hearings are used throughout the assembly, the mainshaft and layshaft having centre bearings for additional support.

First, second and reverse gears are of sliding-spur design, .whilst the third and fourth ratios have constant-mesh helical gears engaged by sliding involute dogs. Fifth gear, also engaged by sliding dog, is direct drive. The ratios afforded are 7.52. 4.27, 2.375. 1.473 and 1 to 1 forward and 7.81 to 1 reverse. Provision is made for a powertake-off drive.

Because the maximum body space is provided, the selector control is carried forward in an enclosed turret to the cab, the gate being of straight-through pattern incorporating an interlock arrangement. The reverse selector is spring-loaded, so that extra pressure is required sideways to engage the gear, Hardy Spicer shafts with needleroller-bearing joints are 'standard in both 7-tonners. The long-wheelbase model has two shafts supported by a self-aligning double-row ball steady bearing mounted on a cross-member, whereas the tipper is equipped with a single shaft.

The fully floating rear axle has a hypoid drive with a ratio of 6.5714 to 1. Its case comprises a cast-steel centre housing with two axle tubes which are ,aaigoted and bolted to it: The hypoid pinion is straddle-mounted on preloaded tapered-roller bearings and meshed with the crown wheel, which is attached by a flange and spigOted -to the four-pin differential housing. Arrangements are made in the design to relieve

t 11 c crown wheel straps of load; this is carried entirely by the centre housing.

An orthodox front Axle is fitted and the steering gear is a M arles cam and double roller unit.

Fully enclosed selfadjusting ball joints are used in the drag link and track rod.

The chassis frame has been constructed to withstand heavy duty such as in Australia, where some of the first vehicles to be produced will be operated. The side rails are 8i ins. deep and 7/32-in, thick, the bottom flange being 21 ins wide and the top flange 2i ins. The bolted-on tubular crosi-members are 4 ins, in diameter. Progressive-action semi-elliptic springs with rubber stops to limit full-bump deflection are fitted to both axles, the springs at the front being 4 ft. long, and those at the rear 4 ft 6 ins. long. All the leaves in the front and rear springs are 3 ins. wide.

The foot brake is assisted by a Lockheed continuous-flow system and takes effect on two-leading-shoe units at all wheels. The servo unit is a multicylindered radial-plunger pump, with a high efficiency over the entire speed range in both directions of rotation. It is mounted on the gearbox and

driven from the mainshaft by twin V belts and a double pulley. The brake drums are 16 ins, in diameter, with shoes 3 ins, wide at the front and 4-41 ins. wide at the rear. To reduce weight and cost, the fuel tank is secured to the chassis by two brackets with all-welded straps which encircle the tank. This method has been found satisfactory on prototype models in the hands of operators.

As in the present 6-tonner, the radiator has a large frontal area and oval brass gilled tubes. The batteries— two six-volt units of 148 amp.-hr. capacity—are carried on the side of the frame opposite the 25-gallon fuel tank and are fully enclosed in a metal case with quickly detachable panels.

Three types of forward-control cab are available. They are of light-alloy, allsteel or coachbuilt ash-frame construction. A common mounting arrange ment with • three flexible units is provided.

The long-wheelbase model is supplied with a flat platform body 16 ft. long and 6 ft. 9 ins, wide, or as a drop-sided lorry with sides and tail

, board 1 ft. 6 ins. deep. The tipping body, lined with steel throughout, is 11 ft.

long, 6 ft. 11 ins.

wide and has sides 2 ft. 1 in, deep. Both models have 9.00 by 20-in/36 by 8-in, heavy-duty tyres.

In his annual statement, reported in "The Commercial Motor" on July 21, Mr. V. C. Ponsonhy, chairman of Tilling Stevens. Ltd., said that a new 6-tonner would also be exhibited at Earls Court. but it is now understood that it will not be available yet.