ALLING

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

HE SHOTS

Every operator spends time trying to find the right vehicle for the job. But how many achieve it?

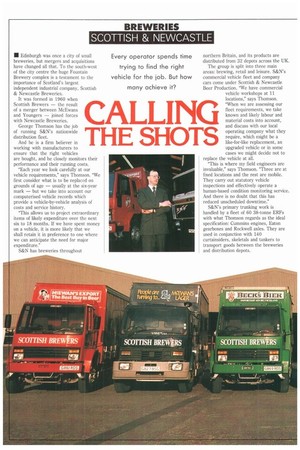

• Edinburgh was once a city of small breweries, but mergers and acquisitions have changed all that_ To the south-west of the city centre the huge Fountain Brewery complex is a testament to the importance of Scotland's largest independent industrial company, Scottish & Newcastle Breweries.

It was formed in 1960 when Scottish Brewers — the result of a merger between McEwans and Youngers — joined forces with Newcastle Breweries.

George Thomson has the job of running S&N's nationwide distribution fleet.

And he is a firm believer in working with manufacturers to ensure that the right vehicles are bought, and he closely monitors their performance and their running costs.

Each year we look carefully at our vehicle requirements," says Thomson. "We first consider what is to be replaced on grounds of age — usually at the six-year mark — but we take into account our computerised vehicle records which provide a vehicle-by-vehicle analysis of costs and service history.

"This allows us to project extraordinary items of likely expenditure over the next six to 18 months. If we have spent money on a vehicle, it is more likely that we shall retain it in preference to one where we can anticipate the need for major expenditure."

S&N has breweries throughout northern Britain, and its products are distributed from 32 depots across the UK.

The group is split into three main areas: brewing, retail and leisure. S&N's commercial vehicle fleet and company cars come under Scottish & Newcastle Beer Production. 'We have commercial vehicle workshops at 11 locations," says Thomson. "When we are assessing our fleet requirements, we take known and likely labour and material costs into account, and discuss with our local operating company what they require, which might be a like-for-like replacement, an upgraded vehicle or in some cases we might decide not to replace the vehicle at all.

"This is where my field engineers are invaluable," says Thomson. "Three are at fixed locations and the rest are mobile. They carry out statutory vehicle inspections and effectively operate a human-based condition monitoring service. And there is no doubt that this has reduced unscheduled downtime."

S&N's primary trunking work is handled by a fleet of 60 38-tonne ERFs with what Thomson regards as the ideal specification: Cummins engines, Eaton gearboxes and Rockwell axles. They are used in conjunction with 140 curtainsiders, skeletals and tankers to transport goods between the breweries and distribution depots. "We use third-party hauliers on longer-distance work," explains Thomson. "Our philosophy is to buy in specialist skills, so in our workshops, for example, we do not employ painters and electricians."

For secondary distribution to pubs S&N uses a mixture of 17-tonne, 10tonne and 7.5-tonne trucks, typically Iveco Fords, Leyland Dafs and Volvos.

"The size used is dictated by operational requirements," says Thomson. "We do use 21-tonne gross urban artics to increase payload, but delivery patterns are constantly changing, and we must consider the options. We are constantly evaluating new vehicle types. We spend some time crawling over a new model before it is loaded and fuelled and sent off on a standard test route. Then we measure its performance — acceleration, hill-climbing and the like, and they are always tested on the same route by the same person."

'Then the test vehicle is sent to one of the operating companies where we assess driveability, comfort and performance. Driver feedback is very important."

Thomson has strong views about the need to find the right vehicles to match S&N's needs. "There is a danger that some manufacturers will try to sell us what they want. We believe in working closely with them, and by doing this we have been able to evolve a 38-tonne unit

that can carry the same payload as the Continentals do with 40-tonne units."

S&N has been an important force in the development of brewery distribution vehicles. Four years ago it designed and built the Bruce, a front-wheel-drive 17-tonner, which achieved a platform height of just 585mm.

"The manufacturers believed that it couldn't be done," Thomson recalls. "It was a valuable exercise, but if anything the Bruce was too low. Today we feel that 30-33in (760-840mm) is a better compromise provided it is a totally flat deck with no wheelarch intrusion.

"In some ways trucks have barely progressed beyond the technology of the horse and cart," reckons Thomson. "We still have to buy chassis that require bodies built by traditional methods. Should we not be looking for complete vehicles?"

In his six years at S&N Thomson has introduced new fleet budgeting and control systems that help to achieve maximum utilisation of the high-mileage vehicles.

At the touch of a button he can call up information on any vehicle, showing its mileage, the fuel burned, and the cost of any maintenance work carried out by company or outside staff.

"With this information, and the hands-on experience of my field engineers, I have a very accurate picture of the fleet, what it is costing us and what it is likely to cost us," he says. "All of this allows us to make sound management decisions on the size and shape of our future fleet.'